Base masking paints and coatings

一种遮蔽涂料、基底的技术,应用在涂层、纤维状填料、对表面涂布液体的装置等方向,能够解决遮蔽力未必充分等问题,达到遮蔽力优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

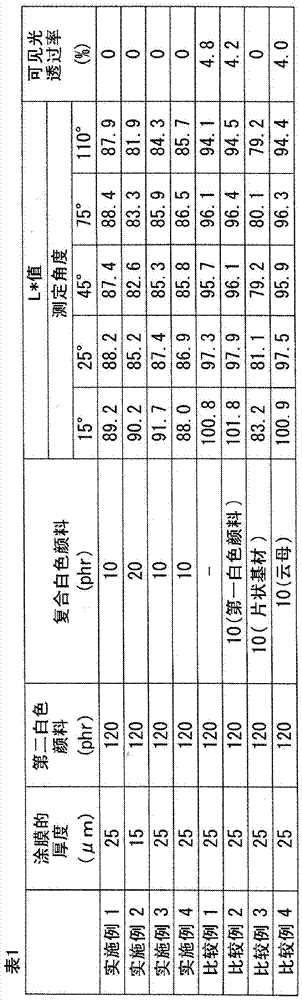

[0092] Hereinafter, the present invention will be explained in detail with examples, but the present invention is not limited to these.

[0093]

[0094]

[0095] 300ml of petroleum spirit was added to a three-necked flask, and 153.8g of aluminum particles (trade name: "Aluminum paste CS420" (metal content: 65%, average particle size: 8μm) as a sheet-like base material, manufactured by Toyo Aluminum Co., Ltd.) And 20.0 g of polymerized carboxylic acid (trade name: "DIACID1550", manufactured by Harima Chemical Co., Ltd.), which is the first compound by thermally polymerizing acrylic acid and soybean oil fatty acid, heated and stirred, then cooled to normal temperature, and filtered, Thus, the degreasing process is performed. In this way, a sheet-like base material subjected to degreasing treatment with the first compound is obtained.

[0096] Next, add 400ml of petroleum spirit as a solvent and TiO as the first white pigment to the mixer 2 (Trade name: "CR-90-2" (average particle s...

Embodiment 2

[0108] In Example 1, the content of the composite white pigment in the base masking paint was 20 phr, and the thickness of the coating film was 15 μm. Except for this, the same procedure as in Example 1 was carried out to obtain a base masking paint on the substrate. The coating of the formed coating film. About the obtained coating film, similarly to Example 1, the visible light transmittance and the L* value of X-rite were measured. The results are shown in Table 1.

Embodiment 3

[0110] In Example 1, 20.0 g of the alicyclic polyamine as the second compound was replaced with 20.0 g of ethylamine. Other than that, the same procedure as in Example 1 was carried out to obtain a substrate with a base masking coating. The coating of the coating. With respect to the obtained coating film, the visible light transmittance and the L* value of X-rite were measured in the same manner as in Example 1. The results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| visible light transmittance | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com