Titanium dioxide barium sulfate coating method

A barium sulfate, titanium dioxide technology, applied in chemical instruments and methods, inorganic pigment treatment, dyeing and washing, etc., can solve the problems of reducing product performance and service life, paint loss of gloss, etc., to improve hiding power, reduce oil absorption, The effect of reducing waste by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

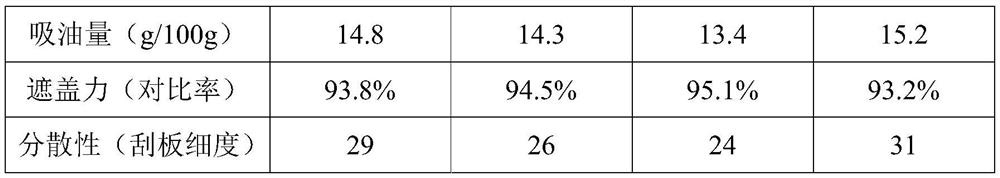

Embodiment 1

[0037] 1. Take the abrasive from the workshop, adjust the concentration of the abrasive to 300g / L, adjust the pH to 10-10.5, and the temperature at 60°C; 2. Co-flow the coating with sodium metaaluminate and dilute sulfuric acid solution for 90 minutes, and aluminum clad The amount of film is 1wt%, and the co-flow coating is completed, and the aging is 90min; 3. Adjust the pH of the slurry to 6.8-7.2, and aging for 90min; 4. Slowly add barium chloride solution (concentration 100g / L), and the coating amount of barium sulfate is 0.5 % by weight, the addition time is 60 minutes, after the addition is complete, it is matured for 90 minutes; 5. Adjust the pH of the slurry to 6.8-7.2, and it is matured for 90 minutes. 6. After the coating is completed, sample 1 is obtained by washing, drying, and grinding, and is ready for use.

Embodiment 2

[0039] The difference from Example 1 is that the coating amount of barium sulfate is changed to 1 wt%, and sample 2 is obtained, which is ready for use.

Embodiment 3

[0041] The difference from Example 1 is that the coating amount of barium sulfate is changed to 2wt% to obtain sample 3, which is ready for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com