Method for freezing and concentrating paper-making reconstituted tobacco refined liquid

A technology of freeze-concentration and reconstitution of tobacco leaves, which is applied in the fields of tobacco, tobacco preparation, and tobacco treatment. It can solve the problems of loss of aroma components, unstable concentration, and waste of resources in tobacco extracts, so as to improve the reuse rate, maintain flavor and Aroma, the effect of avoiding darkening of color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

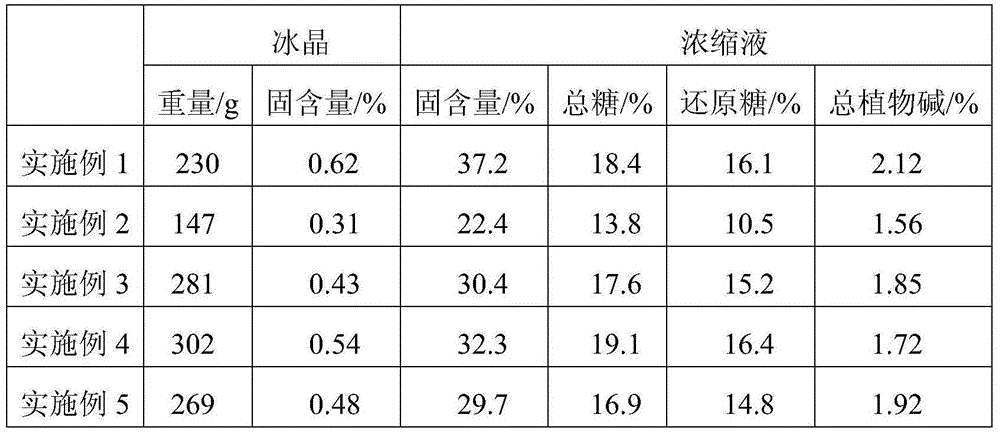

Embodiment 1

[0018] Embodiment 1: The method for freezing and concentrating the refined liquid of reconstituted tobacco leaves by the papermaking method of the present invention comprises the following steps:

[0019] (1) First, take 1L of the refined liquid after extraction of tobacco raw materials, with a solid content of 8.2%, and put it into a freeze concentration tank after cooling to a temperature of 5°C. ℃) to cool down the refined liquid again, turn on the agitator in the freeze concentration tank, ice crystals will be generated on the tank wall, and the ice crystals will enter the refined liquid through agitation to promote the secondary nucleation of the refined liquid to produce large ice crystals. When the freezing time reaches 1h, When the temperature drops to the preset value -12°C, the ice crystals are mature, open the valve at the bottom of the freeze concentration tank, pour the mixture of concentrate and ice crystals into a low-temperature centrifuge, centrifuge at a speed...

Embodiment 2

[0023] Embodiment 2: The method for freezing and concentrating the refined liquid of reconstituted tobacco leaves by the papermaking method of the present invention comprises the following steps:

[0024] (1) First, take 1L of the refined liquid after extraction of tobacco raw materials, with a solid content of 8%, and put it into a freeze concentration tank after cooling to a temperature of 5°C. ℃) to cool down the refined liquid again, turn on the agitator in the freeze concentration tank, ice crystals will be generated on the tank wall, and the ice crystals will enter the refined liquid through agitation to promote the secondary nucleation of the refined liquid to produce large ice crystals. When the freezing time reaches 1h, When the temperature drops to the preset value -12°C, the ice crystals are mature, open the valve at the bottom of the freeze concentration tank, pour the mixture of concentrate and ice crystals into a low-temperature centrifuge, centrifuge at a speed o...

Embodiment 3

[0028] Embodiment 3: The method for freezing and concentrating the refined liquid of reconstituted tobacco leaves by the papermaking process of the present invention comprises the following steps:

[0029] (1) First, take 1L of the refined liquid after extraction of tobacco raw materials, with a solid content of 6.3%, and put it into a freeze concentration tank after cooling to a temperature of 5°C. ℃) to cool down the refined liquid again, turn on the agitator in the freeze concentration tank, ice crystals will be generated on the tank wall, and the ice crystals will enter the refined liquid through agitation to promote the secondary nucleation of the refined liquid to produce large ice crystals. When the freezing time reaches 1h, When the temperature drops to the preset value -12°C, the ice crystals are mature, open the valve at the bottom of the freeze concentration tank, pour the mixture of concentrate and ice crystals into a low-temperature centrifuge, centrifuge at a spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com