Zygopophysis bone drilling device capable controlling bone drilling depth

A technology of articular process and bone drilling, which is applied in medical science, surgery, etc. It can solve the problems of grinding away abnormal bone at the articular process and affecting surgical treatment, and achieves the advantages of convenient operation, enlarged grinding range, and wide implantation space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

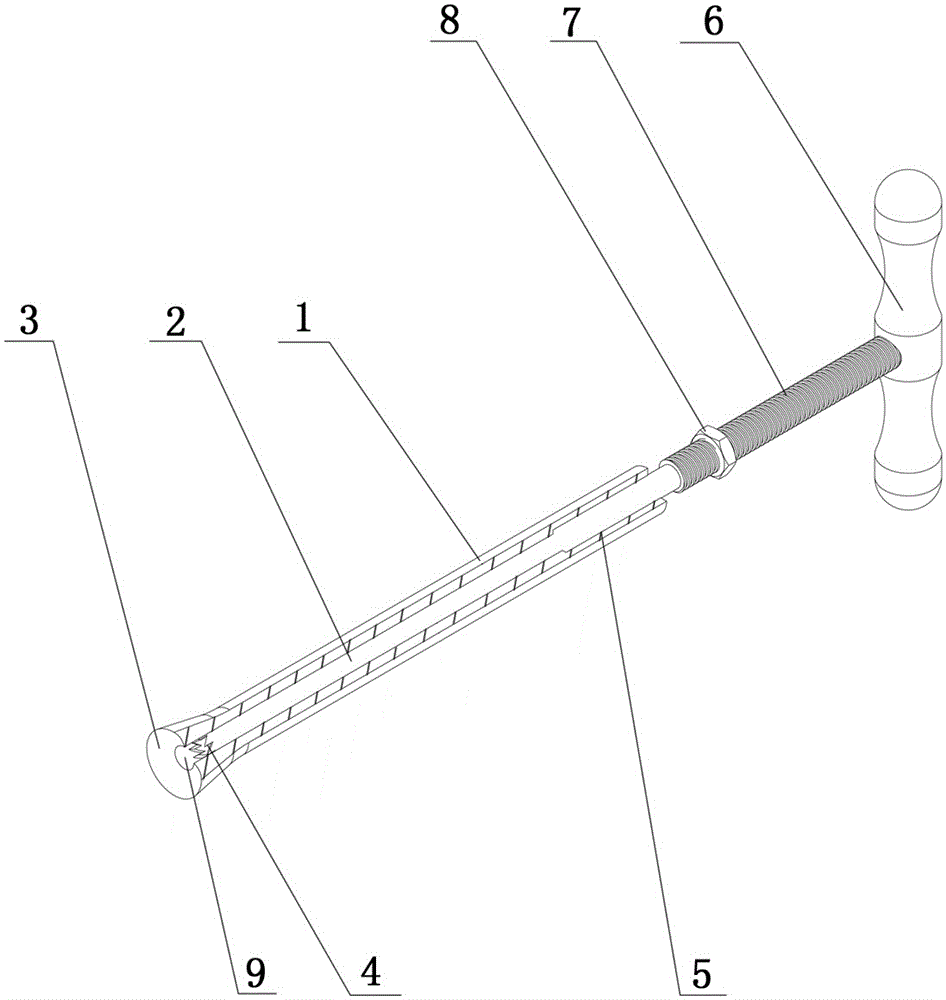

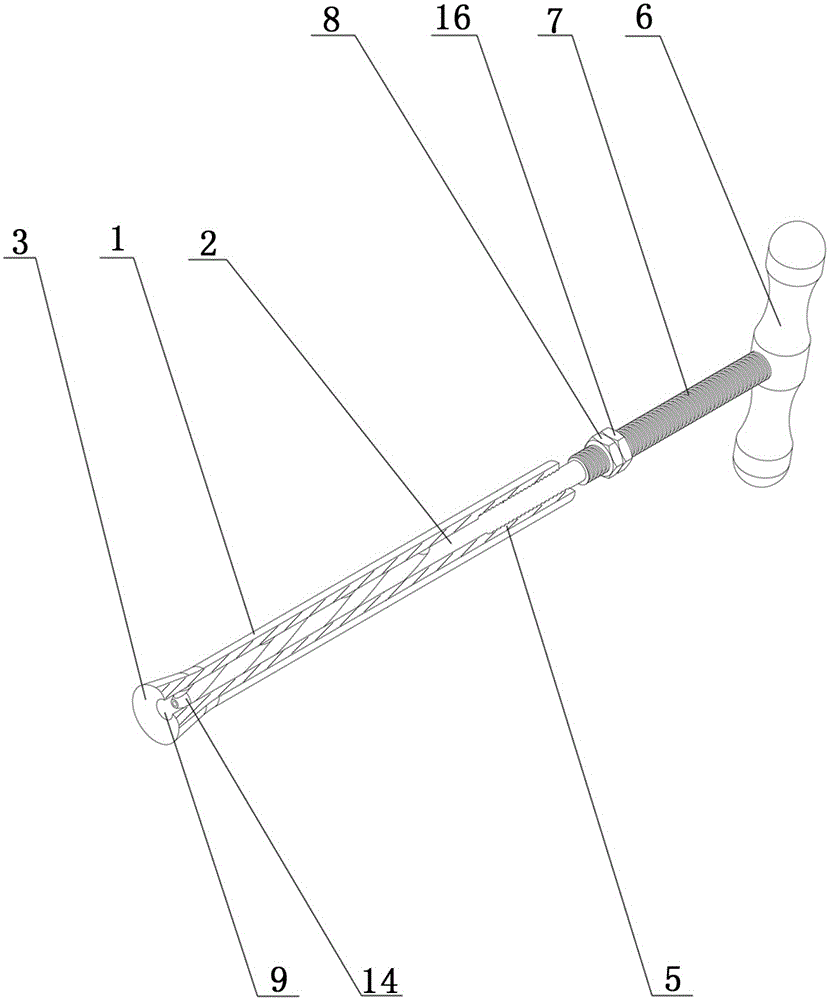

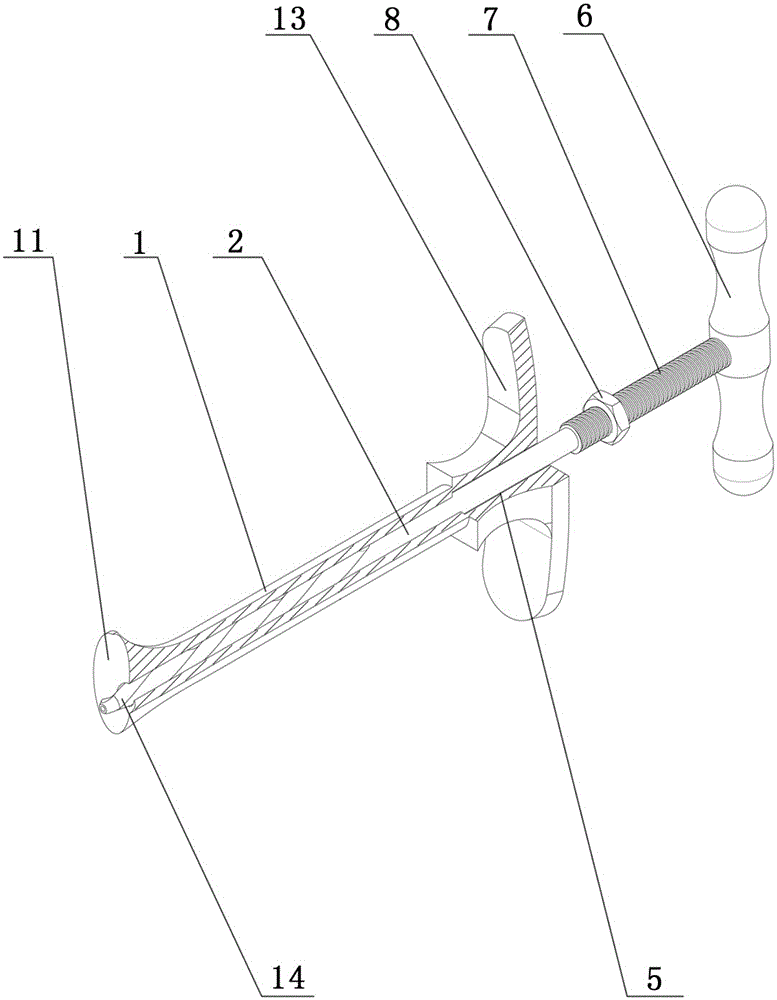

[0020] Such as Figure 1~Figure 4 As shown, the articular process bone drilling device provided by the present invention which can control the bone drilling depth includes a positioning sleeve and a bone grinding drill.

[0021] The bone grinding drill comprises a cylindrical straight shank drill rod 2, an operating handle 6 is connected to the upper end of the drill rod 2, and a drill bit is arranged at the lower end of the drill rod 2. A section of threaded segment 7 is arranged on the drill rod 2 adjacent to the operating handle 6 . The major diameter of the threaded segment 7 is larger than the diameter of the drill rod 2 , and a stop nut 8 is threadedly connected to the threaded segment 7 .

[0022] The positioning sleeve includes a positioning sleeve body 1. The positioning sleeve body 1 is a cylindrical rod structure. On the positioning sleeve body 1, there is an axially penetrated cylindrical channel 9 for inserting the bone grinding drill rod 2. , the axis of the chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com