Preparation method for diatomaceous earth-supported nanometer carbon composite adsorption material

A technology of composite adsorption material and diatomite, which is applied in the field of preparation of diatomite-loaded nano-carbon composite adsorption material, can solve the problems of high reaction equipment and production safety requirements, difficult production wastewater treatment, and potential safety hazards. Adsorption efficiency and adsorption capacity, low cost, good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

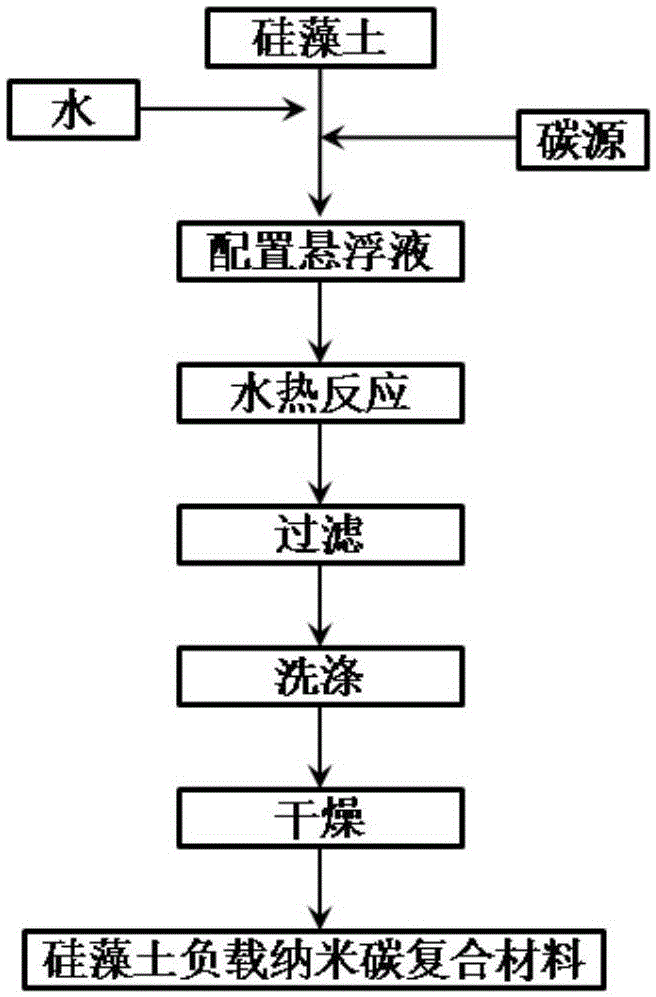

[0015] The specific implementation steps are as follows:

[0016] Raw material introduction: Diatomite comes from Liudaogou mining area in Linjiang, Jilin Province, and its main chemical composition and content are SiO 2 88.19%, Al 2 o 3 3.59%, Fe 2 o 3 1.53%, TiO 2 0.11%, CaO0.62%, K 2 O0.55%, Na 2 O0.11%. Using glucose as carbon source, glucose is analytically pure, white powder, chemical formula is C 6 h 12 o 6 ·H 2 O.

[0017] The preparation process steps are as follows:

[0018] (1) Take 2.5g of diatomite mineral sample and 3.5g of glucose and place them in 75ml of water, and ultrasonically disperse them for 30min, so that the diatomite and glucose are fully and uniformly dispersed in the suspension.

[0019] (2) Add the suspension obtained in step (1) into a 100 mL hydrothermal autoclave, seal it well, and conduct a hydrothermal reaction at a temperature of 180° C. for 12 hours. The obtained precipitated product was alternately washed with absolute ethanol...

Embodiment 2

[0022] The raw materials and steps are the same as in Example 1, except that 3.0 g of diatomaceous earth and 3.5 g of glucose are placed in 75 ml of water; hydrothermal reaction is carried out at 200° C. for 14 hours.

Embodiment 3

[0024] The raw materials and steps are the same as in Example 1, except that 2.5 g of diatomaceous earth and 3.75 g of glucose are placed in 75 ml of water; hydrothermal reaction is carried out at 220° C. for 8 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com