Low temperature flue gas denitration catalyst and preparation method thereof

A denitrification catalyst and low-temperature flue gas technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problem of no catalyst found, achieve excellent denitrification effect, low production cost, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The preparation method of the low-temperature flue gas denitrification catalyst of the present invention comprises the following steps:

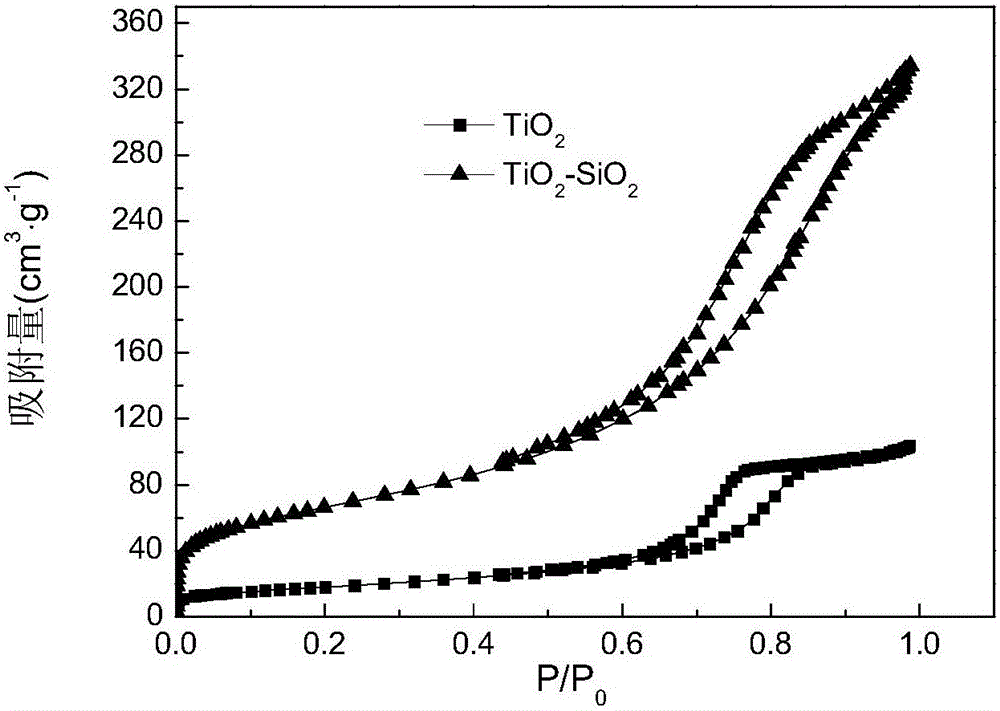

[0045] 1. Preparation of TiO 2 -SiO 2 composite oxide carrier

[0046] (a) take by weighing 16gTiOSO 4 Adding temperature is in the water bath of 40~80 ℃, stirring and dissolving, add 20g silica sol (containing 30wt% SiO 2 ), stirring and standing for 1h to obtain a mixed solution;

[0047] (b) Add dropwise 25wt% ammonia solution in the mixed solution, control the pH value to be 10-11, and generate a suspension;

[0048] (c) The resulting suspension is left standing at 40° C. for 10 h; then filtered and washed to obtain a precursor material;

[0049] (d) drying the obtained precursor material at 110° C. for 10 h, and grinding the dried solid into powder;

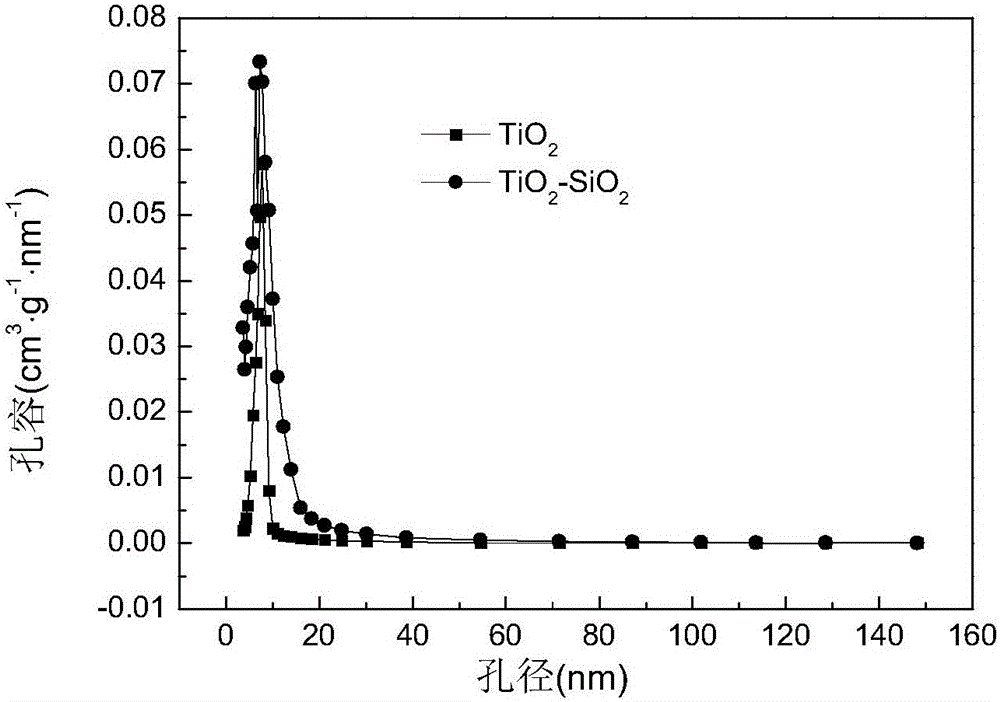

[0050] (e) Calcinate the ground powder at 550°C for 5h, and then sieve the obtained powder to obtain TiO with less than 100 mesh 2 -SiO 2 Composite oxide support, among them...

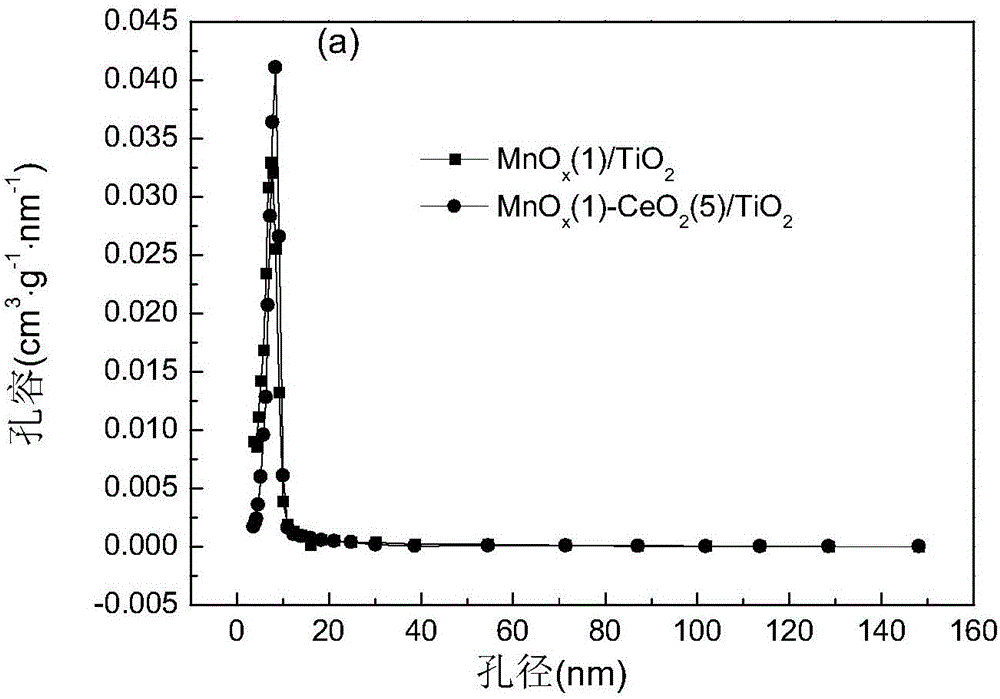

Embodiment 2

[0073] MnOx-CeO 2 / TiO 2 -SiO 2 The synthesis steps of low-temperature flue gas denitrification catalyst are basically the same as in Example 1, only the amount of cerium nitrate added is changed, and 0.504g of cerium nitrate and the prepared 2gMnOx / TiO 2 -SiO 2 Catalyst, obtain target product: MnOx-CeO 2 / TiO 2 -SiO 2 Low temperature flue gas denitrification catalyst. where CeO 2 The loading amount is 10wt%.

Embodiment 3

[0075] MnOx-CeO 2 / TiO 2 -SiO 2 The synthesis steps of low-temperature flue gas denitrification catalyst are basically the same as in Example 1, only the amount of cerium nitrate added is changed, and 0.757g of cerium nitrate and the prepared 2gMnOx / TiO 2 -SiO 2 Catalyst, obtain target product: MnOx-CeO 2 / TiO 2 -SiO 2 Low temperature flue gas denitrification catalyst. where CeO 2 The loading amount is 15wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com