Complete production line for processing myotonin through dry method

A dry processing and production line technology, applied in applications, grain processing, agriculture, etc., can solve the problems of polluting the processing line, potential health and safety hazards, and inability to effectively treat sewage, so as to reduce brown rice damage, improve yield, reduce The effect of water usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

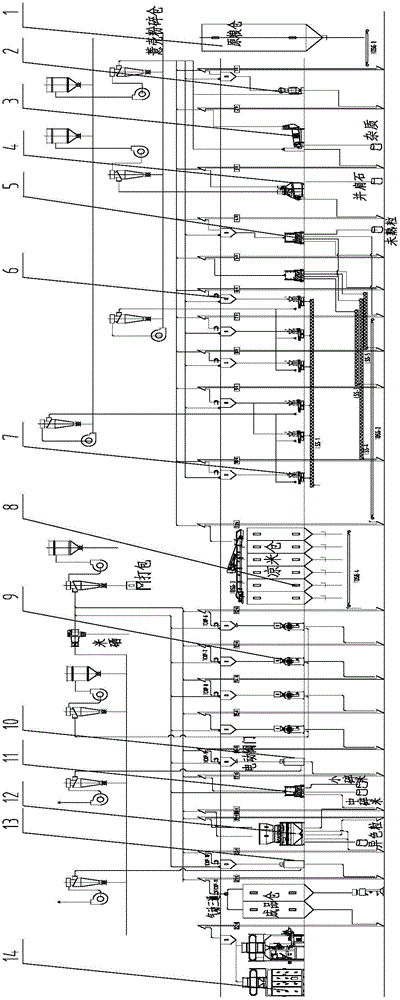

[0024] Such as figure 1 As shown, the present invention provides a complete production line for dry processing of coix seed rice. The complete production line is sequentially provided with an electronic measuring instrument 2, a vibration cleaning device 3, a specific gravity stone removal device 4, a particle classification device 5, and a magnetic field by a raw material feeding bin 1. Iron removal equipment 6, barley shelling equipment 7, cool rice warehouse 8, emery roller milling equipment 9, polishing equipment 10, white rice grading equipment 11, secondary polishing equipment 13 and packaging equipment 14, wherein the polishing equipment 10 and two The secondary polishing equipment 13 is surface water mist humidification and pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com