Aeration chlorine dioxide generator

A chlorine dioxide and generator technology, applied in the direction of chlorine oxide, etc., can solve problems such as difficult to stabilize the flow rate of the metering pump, substandard reaction yield, adverse effects of the generator, etc., to reduce the loss of drugs and reduce the construction workload , the effect of reducing trouble and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in combination with specific embodiments.

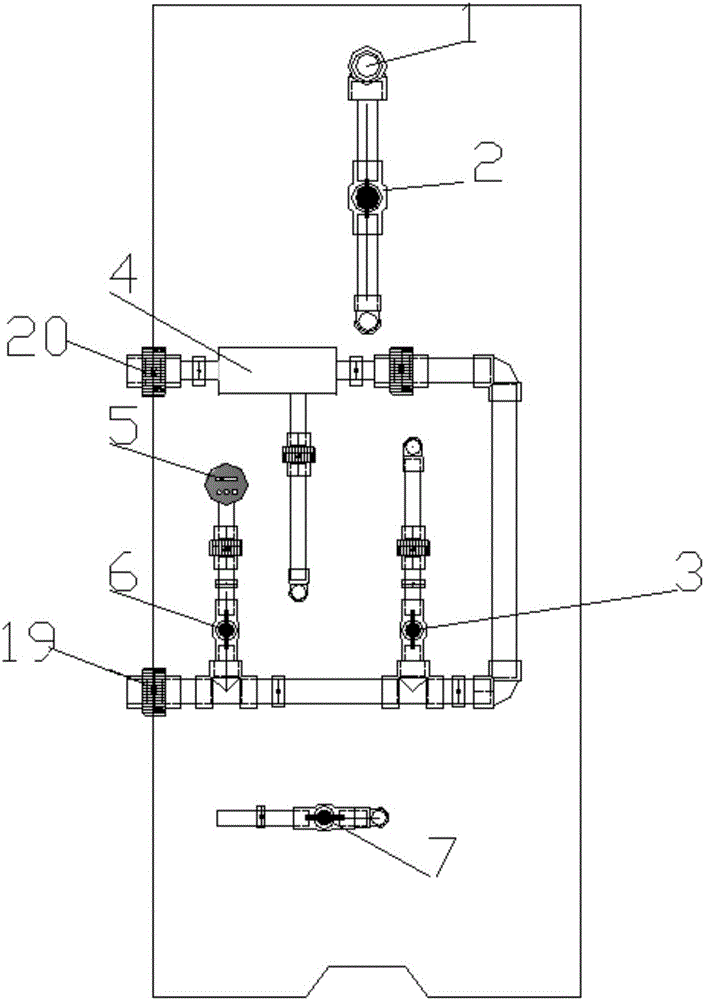

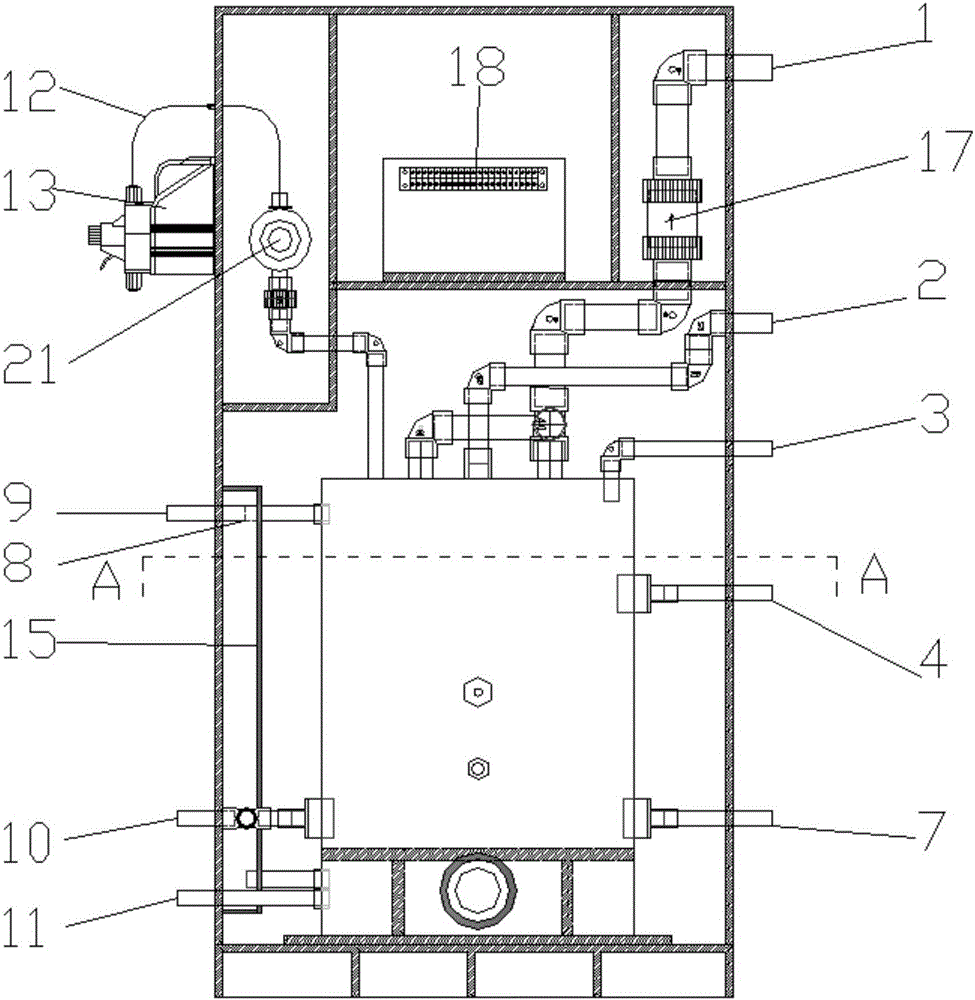

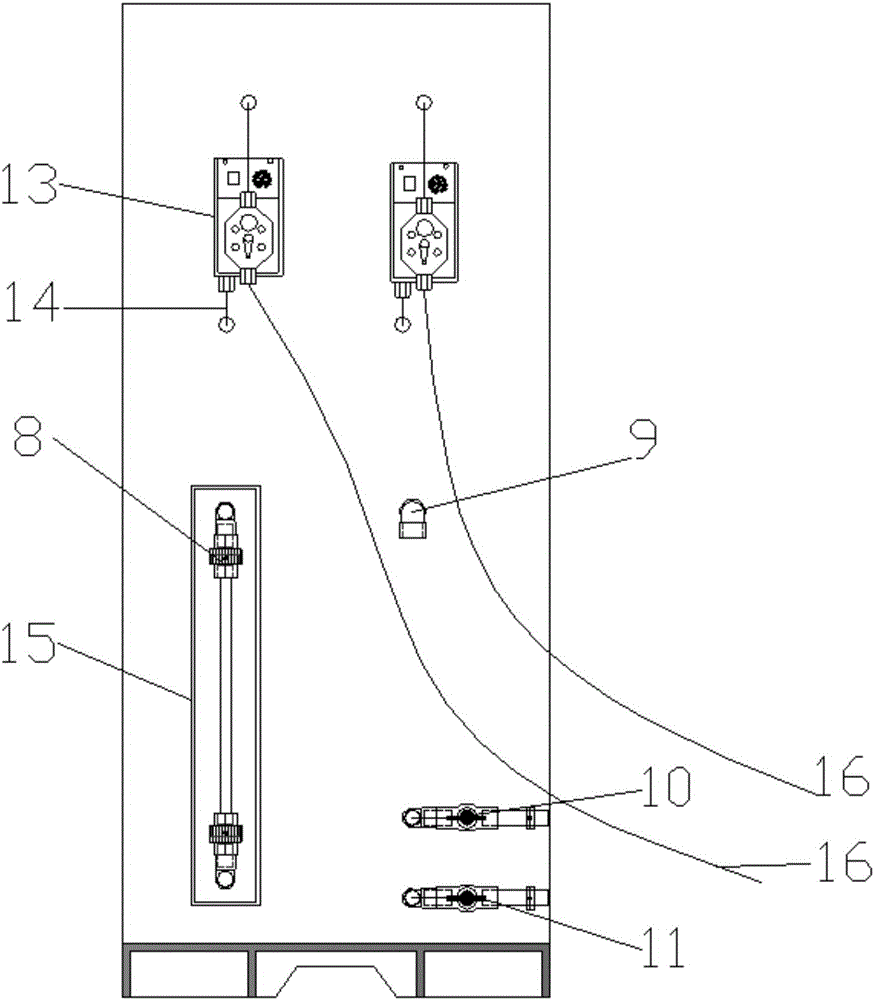

[0039] Such as Figure 4 , Figure 6 and Figure 7 Shown, a kind of aeration type chlorine dioxide generator comprises a water supply system for providing water to the reaction and a reaction system 28 for synthesizing chlorine dioxide, the water supply system communicates with the reactor of the reaction system 28, and the reaction system The reactor includes a reactor body 23 and an aeration pipe assembly, the reactor body 23 includes several reaction chambers 31 connected in sequence, the reaction chamber 31 at one end communicates with the raw material supply device, and the reaction chamber 31 at the other end communicates with the waste liquid outlet , each reaction chamber 31 is in communication with the uniform product outlet, the aeration pipeline is in communication with each reaction chamber 31 through the aeration disc 32 assembly, and the aeration pipeline is i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com