Polyimide film as well as preparation method, flexible substrate and application thereof

A flexible polyimide, polyimide technology, applied in the field of polyimide film and its preparation, can solve the problems of inability to meet the application requirements of flexible displays, and achieve the effect of good high temperature dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

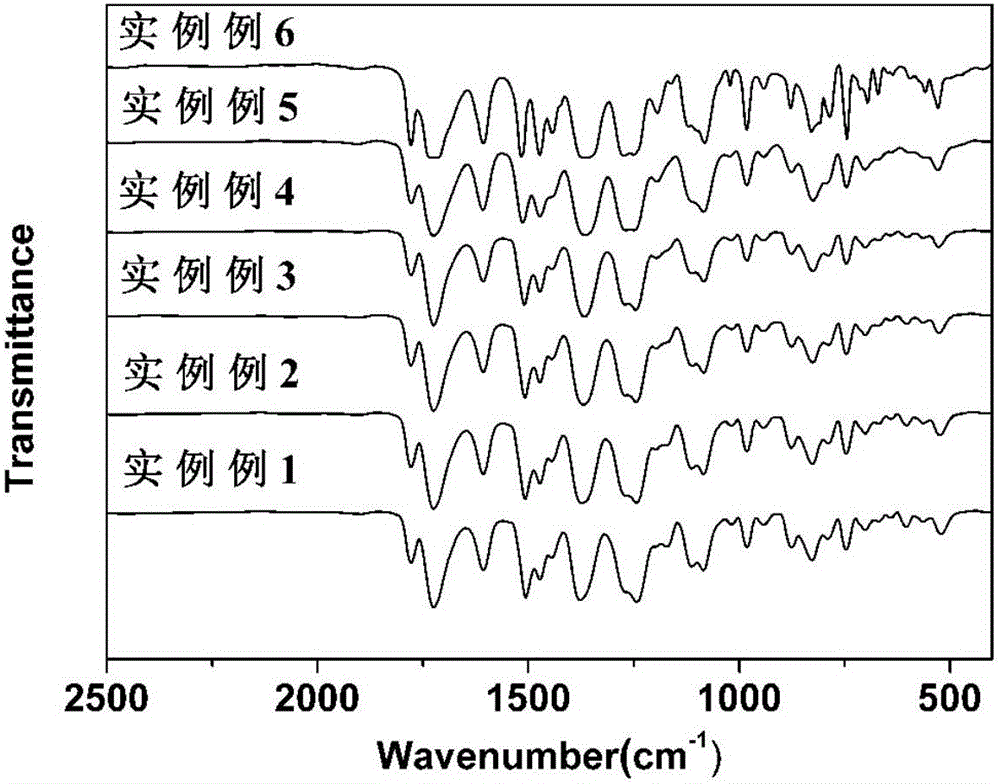

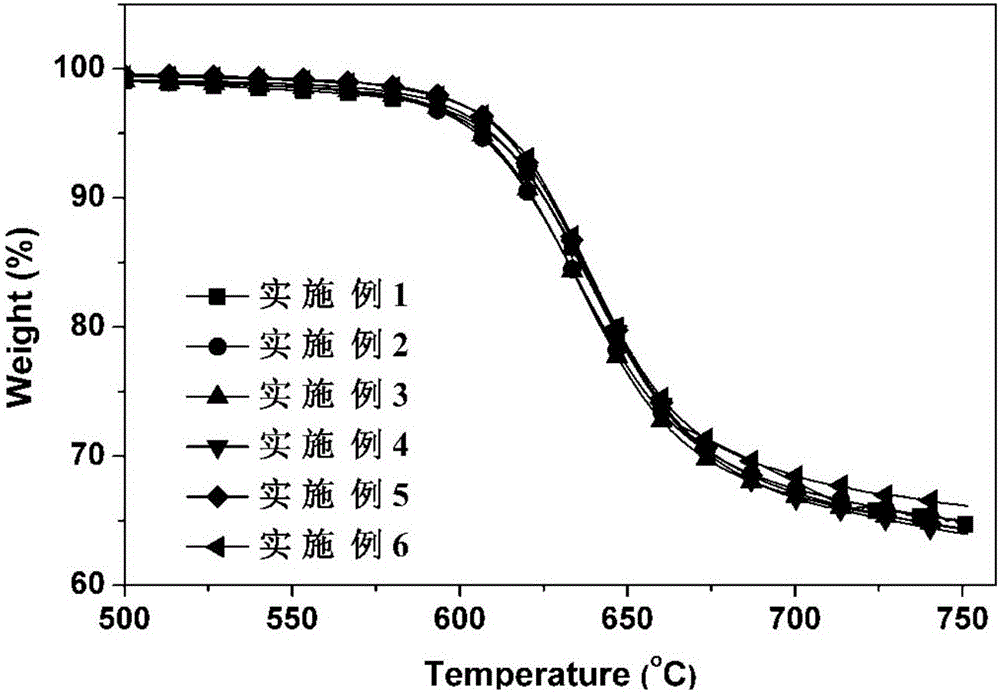

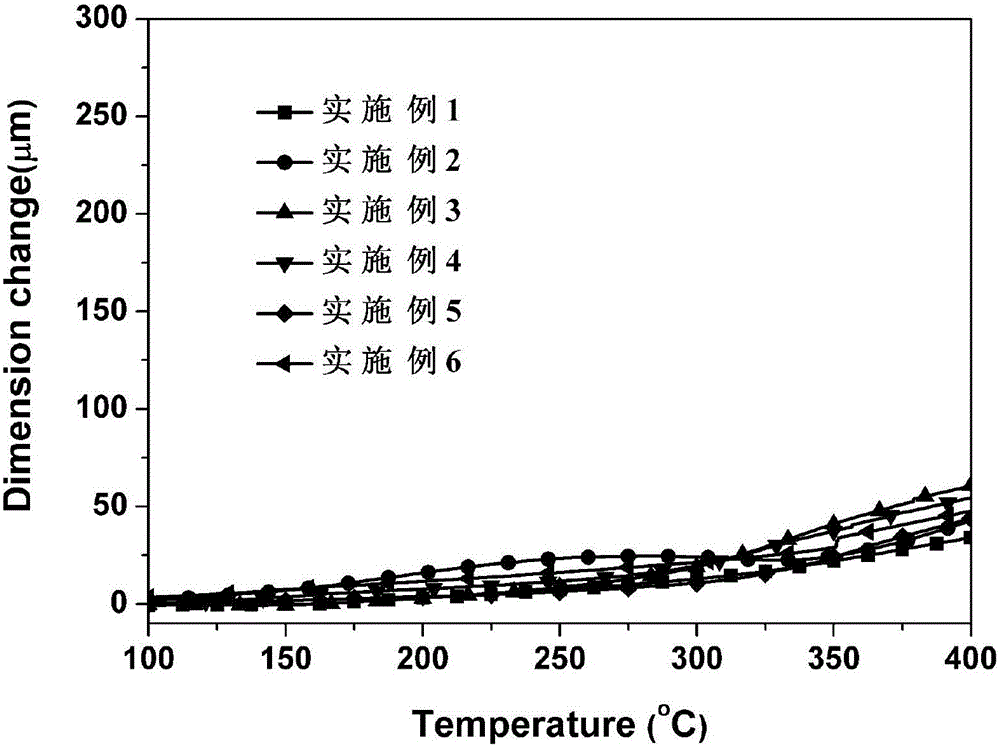

[0037] The polyimide shown in formula I is prepared by sBPDA and 1,3-dimethyl-1,2,3,4-cyclobutane tetraacid dianhydride (MCBDA) in a ratio of 90:10 (molar ratio)

[0038] Add 10.8140 g (0.1 mol) of p-phenylenediamine and 60 g of NMP into a 500 mL three-necked flask equipped with a nitrogen inlet, a thermometer and a feeding port. After stirring at room temperature to dissolve completely, 2.2417g (0.01mol) MCBDA and 26.4798g (0.09mol) sBPDA were added, and 98g NMP was added to adjust the solid content to 20% (weight percent). After stirring at room temperature for 24 h, a light brown viscous solution was obtained. The solution was filtered to remove insoluble impurities. The obtained solution was evenly coated on a clean glass substrate, and the film thickness was controlled by a doctor blade. Place the glass plate in a clean drying oven protected by nitrogen and perform thermal imidization according to the following procedure: 80°C / 3h+120°C / 3h+150°C / 1h+180°C / 1h+250°C / 1h+300°...

Embodiment 2

[0044] Be 85:15 (molar ratio) by ratio sBPDA and 1,3-dimethyl-1,2,3,4-cyclobutane tetraacid dianhydride (MCBDA) polyimide shown in formula I

[0045] Add 10.8140 g (0.1 mol) of p-phenylenediamine and 60 g of NMP into a 500 mL three-necked flask equipped with a nitrogen inlet, a thermometer and a feeding port. After stirring at room temperature to dissolve completely, 3.3626g (0.015mol) MCBDA and 25.0087g (0.085mol) sBPDA were added, and 96g NMP was added to adjust the solid content to 20% (weight percent). After stirring at room temperature for 24 h, a light brown viscous solution was obtained. The solution was filtered to remove insoluble impurities. The obtained solution was evenly coated on a clean glass substrate, and the film thickness was controlled by a doctor blade. Put the glass plate in a clean drying oven protected by nitrogen and carry out thermal imidization according to the following procedure: 80°C / 3h+120°C / 3h+150°C / 1h+180°C / 1h+250°C / 1h+300°C / 1h +350°C / 1h. N...

Embodiment 3

[0051] The polyimide shown in formula I is prepared by sBPDA and 1,3-dimethyl-1,2,3,4-cyclobutane tetraacid dianhydride (MCBDA) in a ratio of 80:20 (molar ratio)

[0052] Add 10.8140 g (0.1 mol) of p-phenylenediamine and 60 g of NMP into a 500 mL three-necked flask equipped with a nitrogen inlet, a thermometer and a feeding port. After stirring at room temperature to dissolve completely, 4.4834g (0.02mol) MCBDA and 23.5376g (0.08mol) sBPDA were added, and 95g NMP was added to adjust the solid content to 20% (weight percent). After stirring at room temperature for 24 h, a light brown viscous solution was obtained. The solution was filtered to remove insoluble impurities. The obtained solution was evenly coated on a clean glass substrate, and the film thickness was controlled by a doctor blade. Put the glass plate in a clean drying oven protected by nitrogen and carry out thermal imidization according to the following procedure: 80°C / 3h+120°C / 3h+150°C / 1h+180°C / 1h+250°C / 1h+300°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com