High-modulus ABS engineering plastic and preparing method thereof

A technology of engineering plastics and high modulus, applied in the field of high modulus ABS engineering plastics and its preparation, can solve the problems of low tensile properties, mechanical properties, limited material application, inability to meet, etc., achieve good dimensional stability, improve yield performance, the effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A high modulus ABS engineering plastic, characterized in that it comprises the following components by mass percentage: ABS resin: 60%, AS resin: 10%, release agent: 0.3%, antioxidant: 0.8%, styrene-mass Toic anhydride copolymer: balance.

[0036] Wherein the AS resin is styrene-acrylonitrile block copolymer, the release agent is release agent P121, and the antioxidant is antioxidant 168.

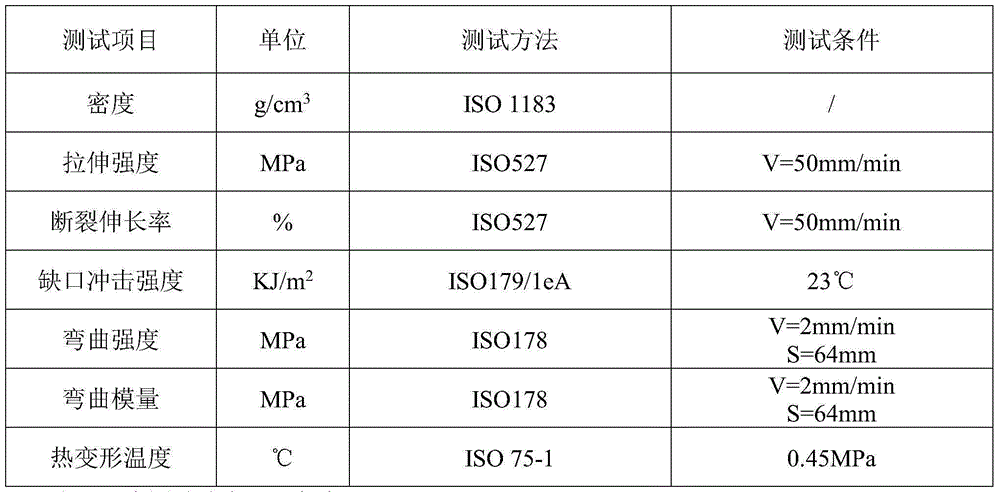

[0037]The performance test data of this material are listed in Table 1.

Embodiment 2

[0039] A kind of high modulus ABS engineering plastics, it is characterized in that it comprises the composition of following mass percent: ABS resin: 66%, AS resin: 8%, release agent: 0.2%, antioxidant: 0.4%, styrene-mass Toic anhydride copolymer: balance.

[0040] Wherein the AS resin is styrene-acrylonitrile block copolymer, the release agent is release agent P121, and the antioxidant is antioxidant 1010.

[0041] The performance test data of this material are listed in Table 1.

Embodiment 3

[0043] A high modulus ABS engineering plastic, characterized in that it comprises the following components by mass percentage: ABS resin: 67%, AS resin: 5%, release agent: 0.1%, antioxidant: 0.8%, styrene-mass Toic anhydride copolymer: balance.

[0044] The AS resin is styrene-acrylonitrile block copolymer, the release agent is release agent P121, and the antioxidant is antioxidant 1076.

[0045] The performance test data of this material are listed in Table 1.

[0046] Table 1

[0047] Test items

[0048] Notched impact strength

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com