Fire retardant coating of super thin steel structure and preparation method thereof

A fire-resistant coating and steel structure technology, applied in fire-resistant coatings, coatings, etc., can solve the problems of complex construction, aesthetic impact, and high cost, and achieve low cost, improved adhesion, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

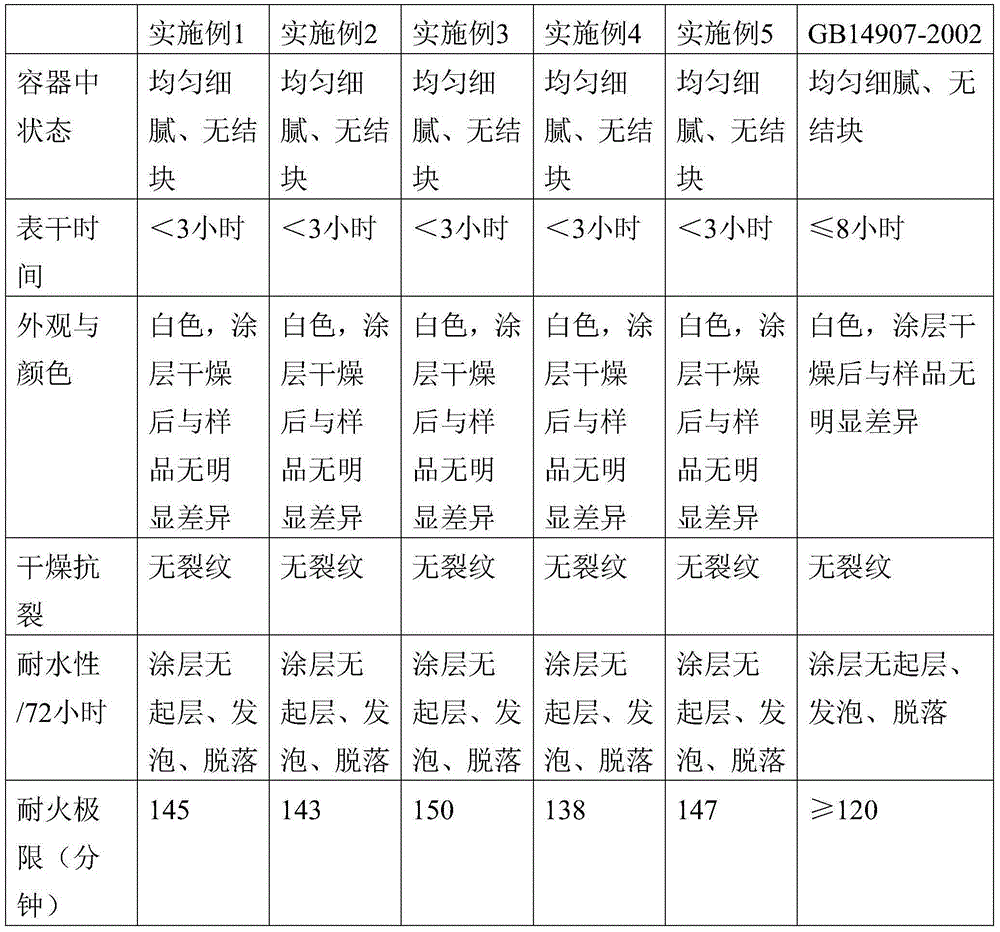

Examples

Embodiment 1

[0051] An ultra-thin fireproof coating for steel structures, comprising the following raw materials in parts by weight:

[0052] 30 parts amino resin

[0053] 20 parts of solvent oil

[0054] Ammonium polyphosphate 20 parts

[0055] 10 parts of titanium dioxide

[0056] 5 parts melamine

[0057] Pentaerythritol 12 parts

[0058] 0.5 parts of bentonite

[0059] 4 parts of chlorinated paraffin.

[0060] As a preferred technical scheme, the solvent oil is 200# solvent oil.

[0061] As a preferred technical solution, the bentonite is selected from 801 bentonite.

[0062] The preparation method of the ultra-thin steel structure fireproof coating of the present invention comprises the following steps:

[0063] (1) Prepare raw materials according to the above-mentioned ratio of parts by weight;

[0064] (2) According to the above ratio, the amino resin and mineral spirits were mixed and stirred evenly, and the stirring time was 12 minutes;

[0065] (3) Then add ammonium pol...

Embodiment 2

[0069] An ultra-thin fireproof coating for steel structures, comprising the following raw materials in parts by weight:

[0070] 32 parts of amino resin

[0071] 18 parts of solvent oil

[0072] Ammonium polyphosphate 22 parts

[0073] 7 parts of titanium dioxide

[0074] 6 parts melamine

[0075] Pentaerythritol 10 parts

[0076] 0.8 parts of bentonite

[0077] 3.5 parts of chlorinated paraffin.

[0078] As a preferred technical scheme, the solvent oil is 200# solvent oil.

[0079] As a preferred technical solution, the bentonite is selected from 801 bentonite.

[0080] The preparation method of the ultra-thin steel structure fireproof coating of the present invention comprises the following steps:

[0081] (1) Prepare raw materials according to the above-mentioned ratio of parts by weight;

[0082] (2) According to the above ratio, the amino resin and mineral spirits were mixed and stirred evenly, and the stirring time was 14 minutes;

[0083] (3) Then add ammonium p...

Embodiment 3

[0087] An ultra-thin fireproof coating for steel structures, comprising the following raw materials in parts by weight:

[0088] 35 parts amino resin

[0089] 15 parts of mineral spirits

[0090] Ammonium polyphosphate 25 parts

[0091] Titanium dioxide 5 parts

[0092] 8 parts melamine

[0093] 8 parts of pentaerythritol

[0094] 1 part bentonite

[0095] 3 parts of chlorinated paraffin.

[0096] As a preferred technical scheme, the solvent oil is 200# solvent oil.

[0097] As a preferred technical solution, the bentonite is selected from 801 bentonite.

[0098] The preparation method of the ultra-thin steel structure fireproof coating of the present invention comprises the following steps:

[0099] (1) Prepare raw materials according to the above-mentioned ratio of parts by weight;

[0100] (2) According to the above ratio, the amino resin and mineral spirits were mixed and stirred evenly, and the stirring time was 16 minutes;

[0101] (3) Then add ammonium polypho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com