Preparation method for foam draining corrosion inhibitor

A technology of foam drainage and corrosion inhibitor, which is applied in the direction of chemical instruments and methods, earthwork drilling, drilling compositions, etc., can solve the problems of no drainage effect, no corrosion, no corrosion inhibition performance, etc., and achieve the reduction of medium Density, performance enhancement, corrosion control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment includes the following steps:

[0039] The first step: Add nonylphenol polyoxyethylene ether TX-18, then add sulfamic acid, mix well and slowly raise the temperature to 125~130℃, control the heating rate at 1.8 hours, and then at 130~140 The reaction was kept at ℃ for 5.5 hours, and the kettle was cooled at 50℃ to obtain nonylphenol polyoxyethylene ether sulfonic acid;

[0040] The molar ratio of the materials in the reaction process: nonylphenol polyoxyethylene ether: sulfamic acid=1:0.995.

[0041] Step 2: Add lauric acid to the reactor, add a certain amount of diethylenetriamine, stir well and raise the temperature to 170~180℃, react for 2.5 hours and then increase the temperature to 240~250℃, react for 4.5 hours, and cool to 110~120℃ , Add a certain amount of nonylphenol polyoxyethylene ether sulfonic acid, stir uniformly, react at 110-120°C for 3.5 hours, cool to 60°C and take out the kettle to obtain nonylphenol polyoxyethylene ether sulfonic acid imidaz...

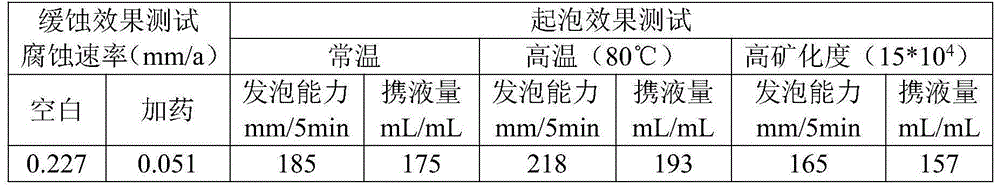

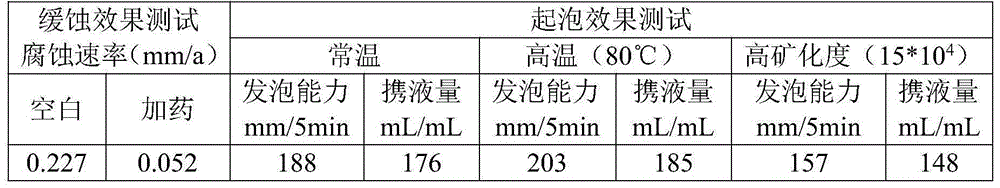

Embodiment 2

[0052] This embodiment includes the following steps:

[0053] The first step: Add nonylphenol polyoxyethylene ether TX-21, then add sulfamic acid, mix well and slowly raise the temperature to 125~130℃, control the temperature rise rate at 1.8 hours, then at 130~140 The reaction was kept at ℃ for 5.5 hours, and the kettle was cooled at 50℃ to obtain nonylphenol polyoxyethylene ether sulfonic acid;

[0054] The molar ratio of the materials in the reaction process: nonylphenol polyoxyethylene ether: sulfamic acid=1:0.995.

[0055] Step 2: Add lauric acid to the reactor, add a certain amount of diethylenetriamine, stir well and raise the temperature to 170~180℃, react for 2.5 hours and then increase the temperature to 240~250℃, react for 4.5 hours, and cool to 110~120℃ , Add a certain amount of nonylphenol polyoxyethylene ether sulfonic acid, stir uniformly, react at 110-120°C for 3.5 hours, cool to 60°C and take out the kettle to obtain nonylphenol polyoxyethylene ether sulfonic acid i...

Embodiment 3

[0066] This embodiment includes the following steps:

[0067] The first step: Add nonylphenol polyoxyethylene ether TX-18, then add sulfamic acid, mix well and slowly raise the temperature to 125~130℃, control the heating rate at 1.8 hours, and then at 130~140 The reaction was kept at ℃ for 5.5 hours, and the kettle was cooled at 50℃ to obtain nonylphenol polyoxyethylene ether sulfonic acid;

[0068] The molar ratio of the materials in the reaction process: nonylphenol polyoxyethylene ether: sulfamic acid=1:0.995.

[0069] Step 2: Add lauric acid to the reactor, add a certain amount of diethylenetriamine, stir well and raise the temperature to 170~180℃, react for 2.5 hours and then increase the temperature to 240~250℃, react for 4.5 hours, and cool to 110~120℃ , Add a certain amount of nonylphenol polyoxyethylene ether sulfonic acid, stir uniformly, react at 110-120°C for 3.5 hours, cool to 60°C and take out the kettle to obtain nonylphenol polyoxyethylene ether sulfonic acid imidaz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com