Gas Drainage Sealing Method Based on Radial Strong Expansion

A technology of gas drainage and gas expansion, which is applied in the field of gas drainage and sealing based on radial strong expansion, can solve the problems of slow sealing speed, waste of sealing materials, shallow sealing depth, etc., and improve the effect of sealing , Saving sealing material, fast foaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

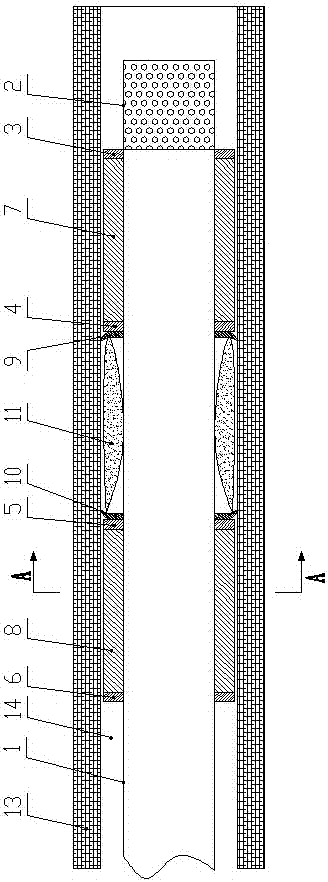

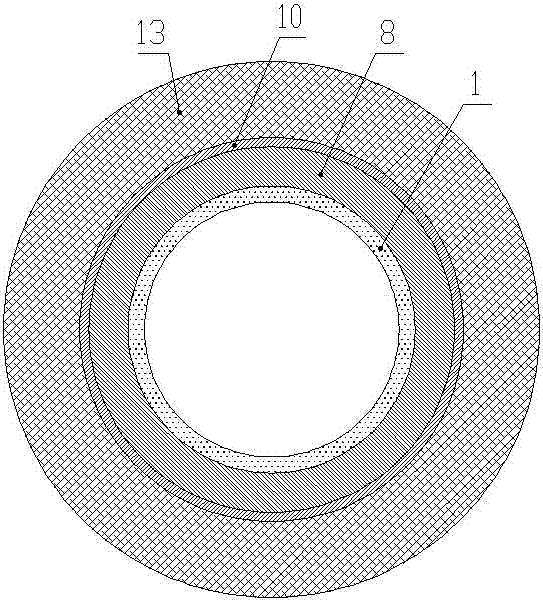

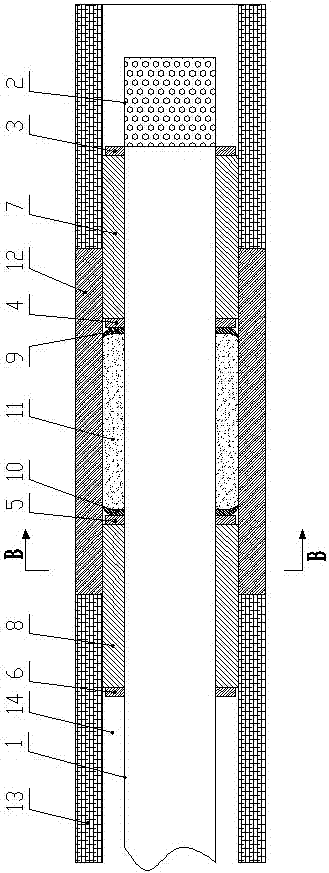

Image

Examples

Embodiment Construction

[0028] The method for gas drainage and sealing based on radially strong expansion of the present invention includes the following steps:

[0029] (1) The test site was selected as the auxiliary air return lane in the north wing of the fourth level of the third mine of Hebi Coal Industry Group. This area is a dangerous area for coal and gas outbursts, with an average coal thickness of 6.8m and a coal seam inclination of 23°~26°; the drill holes control the seam floor elevation between -580 and -620m, the ground elevation is +138.8m, and the buried depth is 718.8m ~758.8m. The permeability coefficient of the vertical coal seam is 3.60~7.15m2 / MPa2•d, and the gas content is 12~15m3 / t.

[0030] First, analyze the development range of cracks in the coal wall of the roadway on site to determine the sealing depth, and use the RFPA-3D numerical simulation method to analyze the development range of cracks in the coal wall of the roadway based on the actual data on site. The model test piec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com