Method for determining content of all elements in galvanized sheet substrate by glow discharge spectrometer

A glow spectrometer and the technology of each element, which are applied in the preparation of test samples, electrical excitation analysis, material excitation analysis, etc., can solve the problems of long process and complicated operation, and achieve low detection limit, simple method and reduced use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

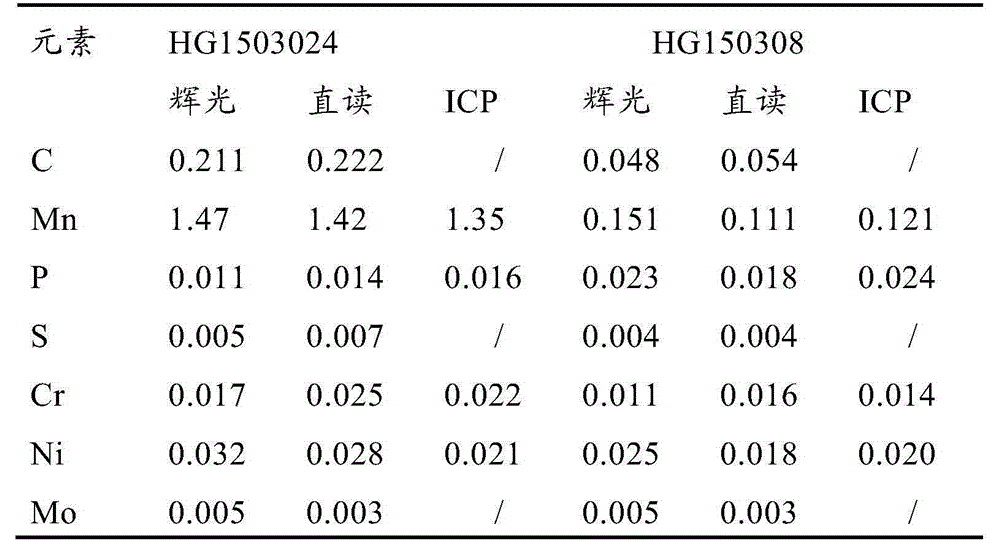

Examples

Embodiment Construction

[0015] The above-mentioned and other technical features and advantages of the present invention will be described in more detail below in conjunction with the embodiments.

[0016] 1. Method summary:

[0017] Debug the instrument, carry out center positioning and curve calibration to make the instrument reach the best state. The sample needs to be cut into a sample block of appropriate size. The surface of the sample block should be flat and free of defects. After simple wiping to remove the surface dirt, the sample is installed in the sample chamber of the spectrometer , Measure the intensity of the spectral line, obtain the change curve of the intensity of each element with time, analyze and calculate the content of each element in the galvanized sheet matrix by analyzing the curve.

[0018] 2. Main equipment:

[0019] 2.1 Cutting machine, which can cut steel samples of different sizes in the cutting area

[0020] 2.2GDProfiler2 glow spectrometer

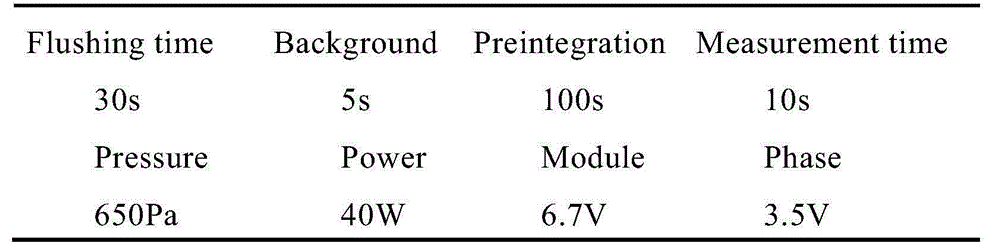

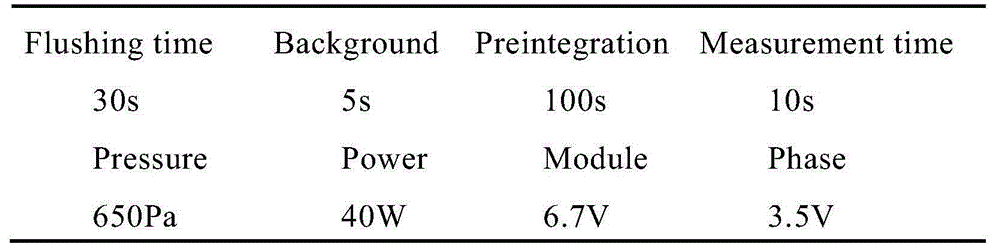

[0021] 3. Electrode spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com