Electromagnetic wire for nuclear power unit and preparation method thereof

A technology for nuclear power units and electromagnetic wires, which is applied in the manufacture of cables/conductors, circuits, insulated cables, etc., can solve the problems of poor craftsmanship, high and low temperature resistance to thermal shock and low reliability, etc., and achieves thermal shock resistance. The effect of excellent performance, excellent nuclear radiation resistance and excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

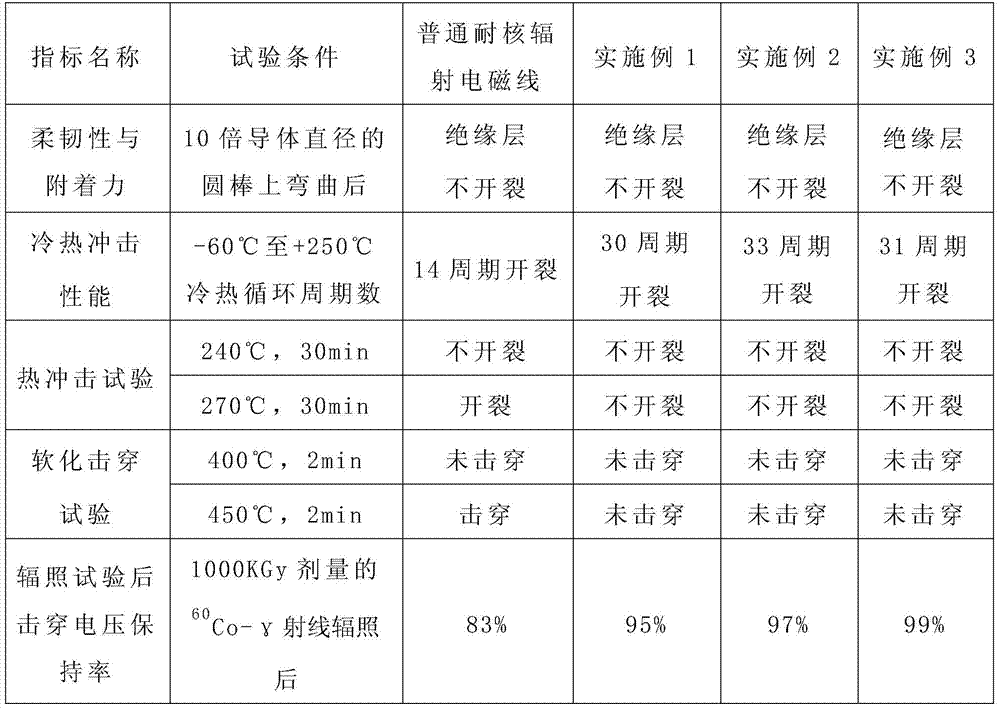

Examples

Embodiment 1

[0025] The electromagnetic wire for nuclear power unit includes an enamelled copper round wire and an insulating layer wrapped around the enamelled copper round wire; the enamelled copper round wire is an aromatic high-temperature resistant polyimide enameled wire; the insulating layer It is composed of single or double glass fiber wrapping and then externally coated with boric acid modified high temperature resistant silicone resin. Wherein, the conductor is an electrical pure copper wire with a diameter of 1.00mm. The wire diameter of the enamelled round copper wire is 1.10 mm; the insulation thickness of both sides of the glass fiber-wrapped insulating layer is 0.15 mm.

[0026] The preparation method of the electromagnetic wire for nuclear power unit is as follows: the copper rod material is drawn on a wire drawing machine to a diameter of 1.00mm, and then annealed in an annealing furnace, and the surface of the copper wire is first coated with an aromatic high-temperature...

Embodiment 2

[0028] The electromagnetic wire for nuclear power unit includes an enamelled copper round wire and an insulating layer wrapped around the enamelled copper round wire; the enamelled copper round wire is an aromatic high-temperature resistant polyimide enameled wire; the insulating layer It is composed of single or double glass fiber wrapping and then externally coated with boric acid modified high temperature resistant silicone resin. Wherein, the conductor is an electrical pure copper wire with a diameter of 1.00 mm. The wire diameter of the enamelled round copper wire is 1.12 mm; the insulation thickness of both sides of the glass fiber-wrapped insulating layer is 0.15 mm.

[0029] The preparation method of the electromagnetic wire for nuclear power unit is as follows: the copper rod material is drawn on a wire drawing machine to a diameter of 1.00mm, and then annealed in an annealing furnace, and the surface of the copper wire is first coated with an aromatic high-temperatur...

Embodiment 3

[0031] The electromagnetic wire for nuclear power unit includes an enamelled copper round wire and an insulating layer wrapped around the enamelled copper round wire; the enamelled copper round wire is an aromatic high-temperature resistant polyimide enameled wire; the insulating layer It is composed of single or double glass fiber wrapping and then externally coated with boric acid modified high temperature resistant silicone resin. Wherein, the conductor is an electrical pure copper wire with a diameter of 1.00 mm. The wire diameter of the enamelled copper round wire is 1.12 mm; the insulation thickness of both sides of the glass fiber-wrapped insulating layer is 0.16 mm.

[0032] The preparation method of the electromagnetic wire for nuclear power unit is as follows: the copper rod material is drawn on a wire drawing machine to a diameter of 1.00mm, and then annealed in an annealing furnace, and the surface of the copper wire is first coated with an aromatic high-temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com