Graphene organic silicon rubber composite material and preparation method thereof

A technology of silicone rubber and composite materials, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve problems such as poor thermal conductivity, achieve improved thermal conductivity, excellent resistance to ultraviolet rays and nuclear radiation, and improve thermal conductivity sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

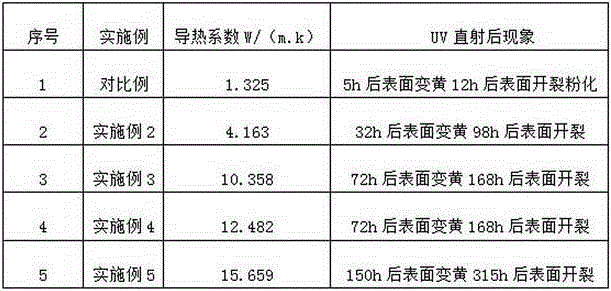

Examples

Embodiment 1

[0021] A kind of graphene silicone rubber composite material, comprises the component of following parts by weight:

[0022] 15-39 parts of high phenyl silicone rubber, 1-40 parts of graphene, 55-98 parts of thermal conductive filler, 1-5 parts of silazane, and 1-5 parts of catalyst.

[0023] In this embodiment, the high phenyl silicone rubber is made of tetramethylcyclotetrasiloxane, tetramethyltetraphenylcyclotetrasiloxane, octaphenylcyclotetrasiloxane, divinyltetramethyldi At least two of the siloxanes are polymerized in any proportion under alkaline conditions.

[0024] In this embodiment, the molecular weight of the high-phenyl silicone rubber is 400,000-900,000, the phenyl mass content of the high-phenyl silicone rubber is 30%-70%, and its refractive index is greater than 1.54.

[0025] In this embodiment, the thermally conductive filler is composed of micron alumina compounded with various particle sizes, and the particle size of the micron alumina is 1-400 μm. Furthe...

Embodiment 2

[0029] A kind of graphene silicone rubber composite material, comprises the component of following parts by weight:

[0030] 15 parts of high phenyl silicone rubber, 1 part of graphene, 98 parts of thermally conductive filler, 5 parts of silazane, and 1 part of catalyst.

[0031] In this embodiment, the high phenyl silicone rubber consists of 10 parts of octaphenylcyclotetrasiloxane, 90 parts of tetramethyltetraphenylcyclotetrasiloxane and 2 parts of divinyltetramethyldisiloxane Polymerized under alkaline conditions.

Embodiment 3

[0033] A kind of graphene silicone rubber composite material, comprises the component of following parts by weight:

[0034] 32 parts of high phenyl silicone rubber, 11 parts of graphene, 75 parts of thermally conductive filler, 1 part of silazane, and 4 parts of catalyst.

[0035] In this embodiment, the high phenyl silicone rubber is polymerized by 10 parts of octaphenylcyclotetrasiloxane and 90 parts of tetramethyltetraphenylsiloxane under alkaline conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com