Composite pipeline

A technology of composite pipes and pipe materials, which is applied in the field of composite pipes, can solve problems such as low strength, weak tensile strength, and pipe rupture, and achieve the effects of high mechanical properties, convenient machining, and improved high temperature tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

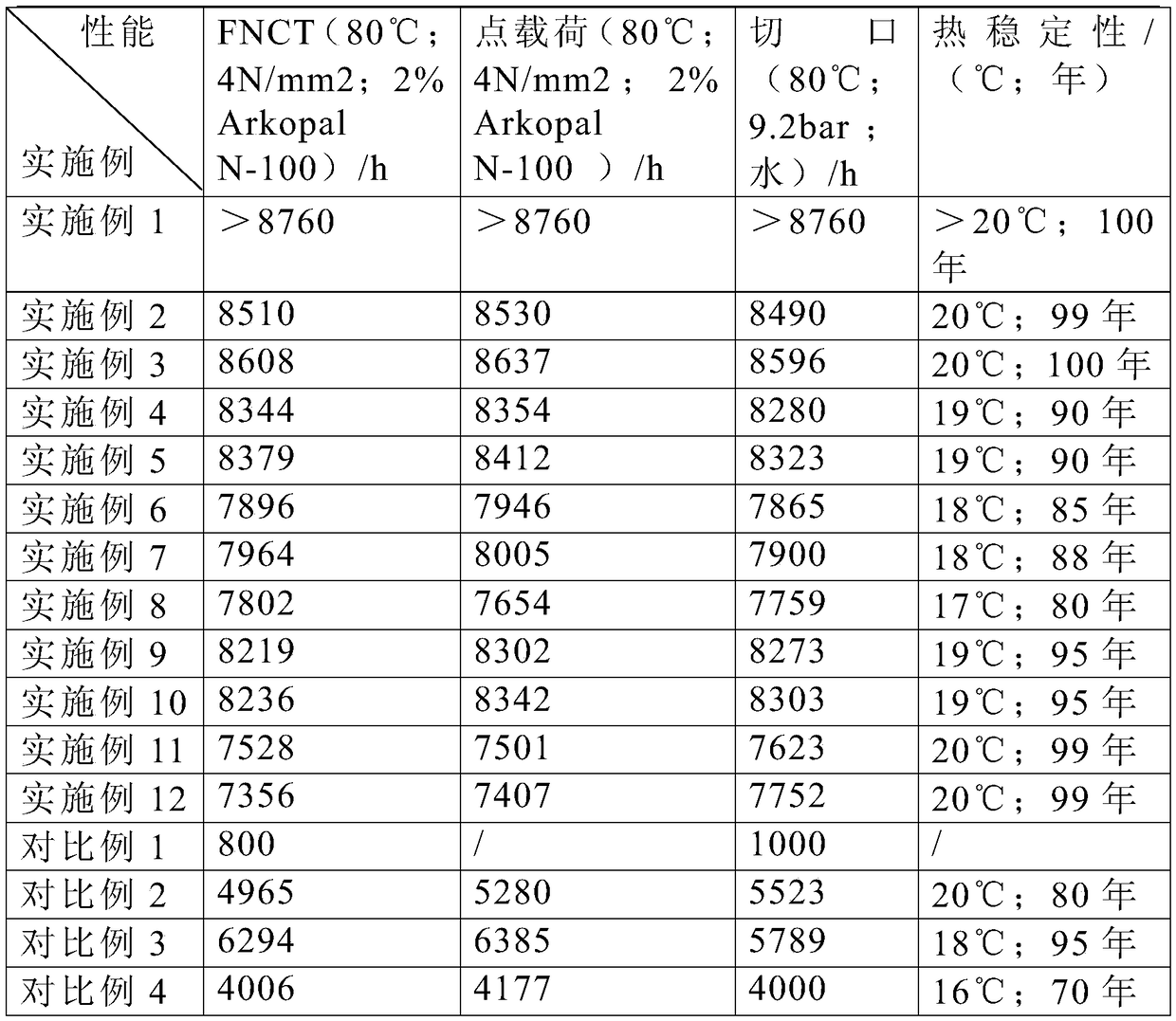

Examples

Embodiment 1

[0034] Ingredients: Weigh the raw materials of the middle layer tube, including the following parts by weight: high-density polyethylene: 100 parts, polyimide: 4 parts, filler: 10 parts, color masterbatch: 15 parts, azodicarbonamide: 0.05 parts, weigh the raw materials of the inner and outer tubes, including the following parts by weight: 100 parts of ultra-high molecular weight polyethylene, 12 parts of polyimide, 23 parts of high-density polyethylene, 15 parts of color masterbatch, Pearl powder: 8 parts, lanthanum oxide: 1 part, paraffin wax: 2 parts, wherein, pearl powder and lanthanum oxide are particles with a particle diameter of 50 nm.

[0035] Extrusion: Mix the raw materials of the middle layer pipe evenly, send them into the No. 1 extruder to get the pipe material 1, mix the raw materials of the inner and outer layer pipes evenly, and send them into the No. 2 extruder to get the pipe material 2.

[0036] Co-extrusion molding: feed pipe material 2, pipe material 1, an...

Embodiment 2

[0039] Ingredients: Weigh the raw materials of the middle layer tube, including the following parts by weight: high-density polyethylene: 80 parts, polyimide: 3 parts, filler: 5 parts, color masterbatch: 10 parts, azodicarbonamide: 0.01 parts, weigh the raw materials of the inner and outer tubes, including the following parts by weight: 80 parts of ultra-high molecular weight polyethylene, 8 parts of polyimide, 15 parts of high-density polyethylene, 12 parts of color masterbatch, Pearl powder: 6 parts, lanthanum oxide: 0.1 part, paraffin wax: 1 part, wherein, pearl powder and lanthanum oxide are particles with a particle diameter of 20 nm.

[0040] Extrusion: Mix the raw materials of the middle layer pipe evenly, send them into the No. 1 extruder to get the pipe material 1, mix the raw materials of the inner and outer layer pipes evenly, and send them into the No. 2 extruder to get the pipe material 2.

[0041] Co-extrusion molding: feed pipe material 2, pipe material 1, and p...

Embodiment 3

[0044]Ingredients: Weigh the raw materials of the middle layer tube, including the following parts by weight: high-density polyethylene: 120 parts, polyimide: 5 parts, filler: 15 parts, color masterbatch: 20 parts, azodicarbonamide: 0.1 parts, weigh the raw materials of the inner and outer tubes, including the following parts by weight: 120 parts of ultra-high molecular weight polyethylene, 15 parts of polyimide, 30 parts of high-density polyethylene, 18 parts of color masterbatch, Pearl powder: 10 parts, lanthanum oxide: 2 parts, paraffin wax: 3 parts, wherein, pearl powder and lanthanum oxide are particles with a particle diameter of 20-80nm.

[0045] Extrusion: Mix the raw materials of the middle layer pipe evenly, send them into the No. 1 extruder to get the pipe material 1, mix the raw materials of the inner and outer layer pipes evenly, and send them into the No. 2 extruder to get the pipe material 2.

[0046] Co-extrusion molding: feed pipe material 2, pipe material 1, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com