A miniaturized electronic module circuit system and its manufacturing method

A circuit system and electronic module technology, which is applied in the field of electronic module circuit systems, can solve the problems of poor anti-electromagnetic interference ability of module circuits, miniaturized production cost, performance impact, large unit module circuit assembly volume, etc., to achieve process simplification, The effect of avoiding metal fatigue and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

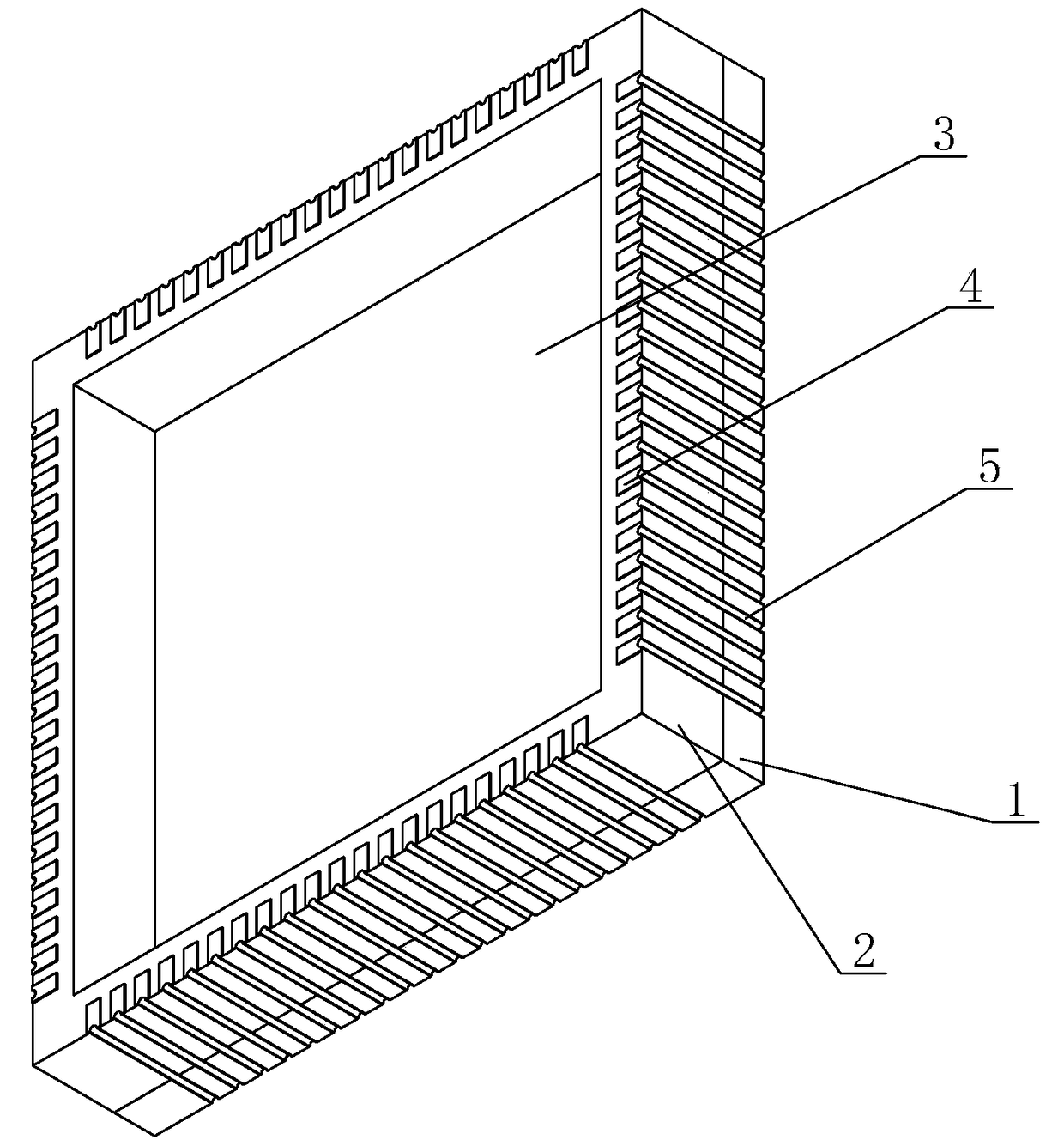

[0031] see figure 1 as shown, figure 1 It is a schematic perspective view of the miniaturized electronic module circuit system provided in Embodiment 1 of the present invention.

[0032] In this embodiment, a miniaturized electronic module circuit system includes a square carrier board 1 for mounting components and a square cavity frame 2 with a hollow structure, the carrier board 1 is made of several layers of printed boards, Both sides of it are set as device assembly surfaces. The cavity frame 2 is formed by stacking several hollow printed boards, and a cavity 3 for accommodating components is formed inside. The outer dimensions of the cavity frame 2 The same as the outer dimensions of the carrier board 1, one side of the cavity frame 2 is bonded to the carrier board 1, and the other side is as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com