Wet type high-temperature sterilization method for aquatic products through tunnels and microwaves and processing and testing equipment

A technology of high-temperature sterilization and test equipment, which is applied in the fields of food preservation, food science, and application. It can solve problems such as unbalanced internal and external pressure, bag swelling, and food quality that affects the effect of sterilization, and achieves the effect of high temperature uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

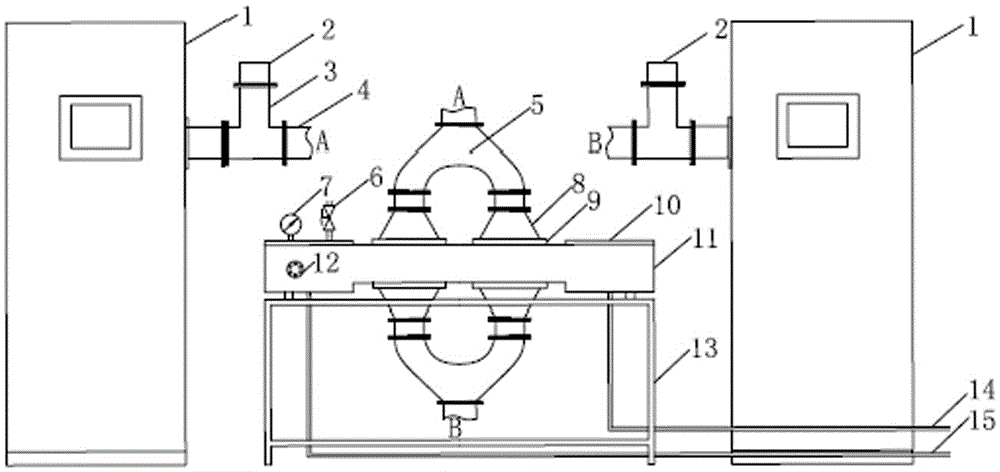

[0027] Wet aquatic product tunnel microwave high-temperature sterilization processing test equipment, including three units: microwave generating device, microwave resonant cavity and water circulation system;

[0028] The microwave generating device comprises a microwave source 1, a water load 2, a circulator 3, a connecting waveguide 4, a power divider 5 and a pyramidal horn 8; the microwave source 1 is connected to one end of the circulator 3, and the circulator 3 is another The two ends are respectively connected to the water load 2 and the connection waveguide 4; the connection waveguide 4 is connected to the pyramidal horn 8 through the power divider 5, and the number of the pyramidal horn 8 is twice the number of the power divider 5, and the power divider 5 is divided into two branches, each connected to a pyramid horn 8;

[0029] The microwave resonant cavity includes an exhaust valve 6, a pressure gauge 7, a medium coupling window 9, a feed door 10, a resonant cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com