Tea polyphenol tobacco humectant and application thereof in cigarettes

A technology of tea polyphenols and humectants, which is applied in the field of preparation and its application in cigarettes, can solve the problems of increased content of harmful substances such as acetaldehyde, irritating smell of smoke, and unfavorable taste of cigarettes, etc., so as to reduce the consumption of tobacco leaves , Improve the effect of sensory moisturizing and coordination of smoke aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

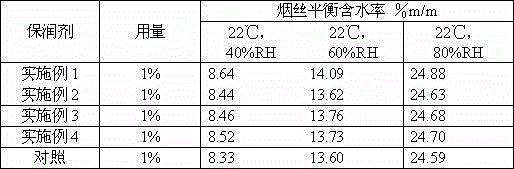

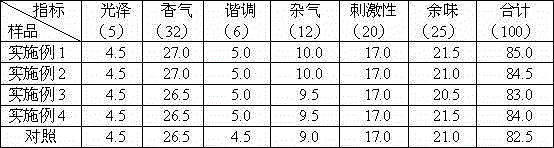

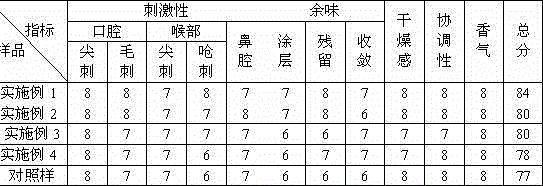

[0017] Example 1. Weigh 100g of tea polyphenol powder samples, keep the temperature in an oven at 120°C for 120min, crush them through a 40-mesh sieve to obtain a neutral sample of modified tea polyphenols; weigh 100g of tea polyphenol powder samples, add 10g of 2% hydrochloric acid solution , stir evenly to form a semi-dry material, keep the temperature in an oven at 120°C for 120min, and pulverize through a 40-mesh sieve to obtain a modified tea polyphenol acidified sample; weigh 100g of tea polyphenol powder sample and add 10g of a mass fraction of 2% sodium hydroxide solution, Stir evenly to form a semi-dry material, keep the temperature in an oven at 120°C for 120 minutes, and pulverize through a 40-mesh sieve to obtain an alkalized sample of modified tea polyphenols. Weigh 30g of the prepared neutral sample, 5g of the acidified sample, 5g of the alkalized sample and 5g of propylene glycol and add them to 55g of water to adjust the pH to neutral. Add 0.5g preservative an...

Embodiment 2

[0018] Example 2. Weigh 100g of tea polyphenol powder sample, keep the temperature in an oven at 100°C for 145min, and crush it through a 40-mesh sieve to obtain a modified tea polyphenol neutral sample; weigh 100g of tea polyphenol powder sample and add 15g of 1% sodium hydroxide solution by mass fraction , stir evenly to form a semi-dry material, keep the temperature in an oven at 100°C for 145min, and pulverize through a 40-mesh sieve to obtain a modified tea polyphenol alkalized sample. Weigh 20 g of the prepared neutral sample and 20 g of the alkalized sample and add them to 60 g of water to adjust the pH to neutral. Add 0.5g preservative and 0.5g defoamer to prepare tea polyphenol moisturizer. Weigh 10g of humectant and spray evenly onto 1000g of shredded tobacco. The amount of humectant is 1% of the mass of tobacco leaves. Cigarette samples were prepared from the shredded tobacco.

Embodiment 3

[0019] Example 3. Weigh 100g of tea polyphenol powder sample, keep the temperature in an oven at 150°C for 30min, crush it through a 40-mesh sieve to obtain a modified tea polyphenol neutral sample; weigh 100g of tea polyphenol powder sample, add 20g of 0.5% hydrochloric acid solution , stir evenly to form a semi-dry material, keep the temperature in an oven at 150°C for 30 minutes, and pulverize through a 40-mesh sieve to obtain a modified tea polyphenol acidified sample. 30 g of the prepared neutral sample, 20 g of the acidified sample, and 10 g of propylene glycol were weighed and added to 40 g of water to adjust the pH to neutral. Add 0.5g preservative and 0.5g defoamer to prepare tea polyphenol moisturizer. Weigh 10g of humectant and spray evenly onto 1000g of shredded tobacco. The amount of humectant is 1% of the mass of tobacco leaves. Cigarette samples were prepared from the shredded tobacco.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com