A Dry Packed Tower Capable of Quickly Unloading Packing

A packed tower, dry technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of inconvenient use, large investment, and large land occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

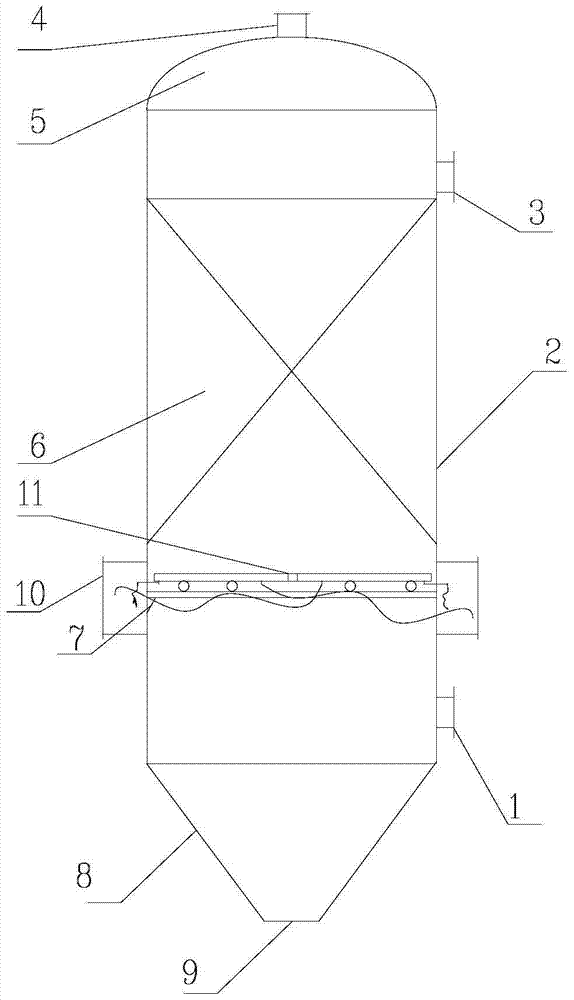

[0065] use Figure 8 to Figure 14 The dry-type packed tower with a layer of misplaced composite packing support is used to remove naphthalene from coke oven gas, and it can also be called dry-type naphthalene-removed tower. Composition of coke oven gas: nitrogen N 2 : 3%, Oxygen O 2 : 0.5%, hydrogen H 2 : 60%, carbon monoxide CO: 7.5%, carbon dioxide CO 2 : 2.3%, methane CH 4 : 24.3%, heavy hydrocarbons C n h m : 2.4%. The content of main impurities: tar mist: 50mg / Nm 3 , Naphthalene: 400mg / Nm 3 , Benzene: 4000mg / Nm 3 , hydrogen sulfide: 200mg / Nm 3 . The content of main impurities after purification is required: tar mist: less than 5mg / Nm 3 , naphthalene: less than 20mg / Nm 3 , hydrogen sulfide: less than 5mg / Nm 3 . Single tower processing coke oven gas volume 15000Nm 3 / h.

[0066] Control the operating pressure of the above-mentioned dry denaphthalene removal tower to 20kPa, the maximum operating temperature to 260°C, and the diameter of the tower to 4.8 mete...

example 2

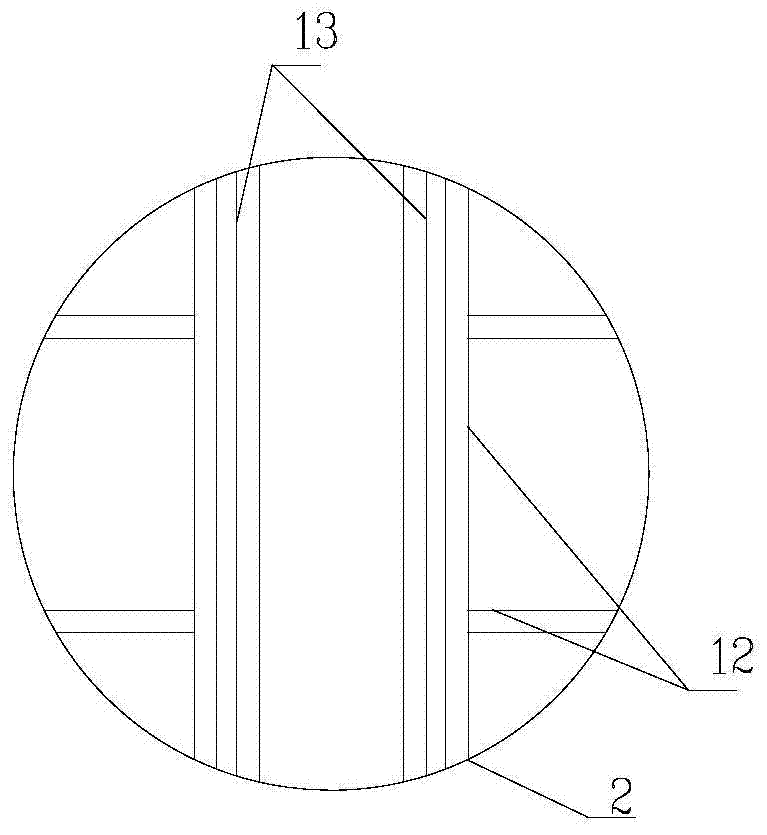

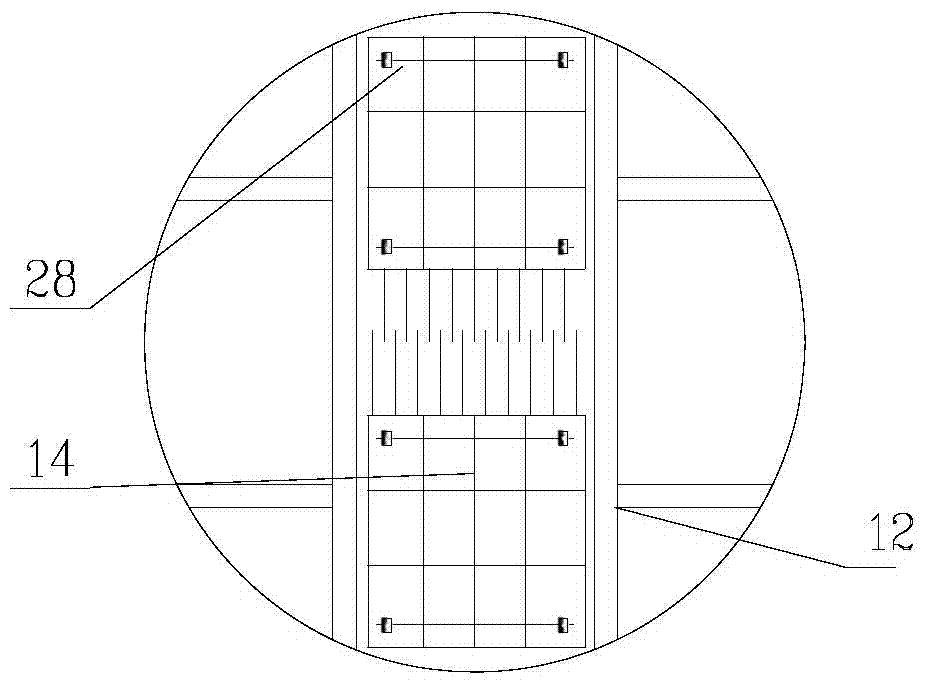

[0069] use Figure 1 to Figure 7 A dry-type packed tower with a layer of fitted composite packing support removes benzene from coke oven gas, and it can also be called a dry-type debenzene tower. Composition of coke oven gas: nitrogen N 2 : 3%, Oxygen O 2 : 0.3%, hydrogen H 2 : 61.2%, carbon monoxide CO: 6.5%, carbon dioxide CO 2 : 2.0%, methane CH 4 : 24.6%, heavy hydrocarbons C n h m : 2.4%. The content of main impurities: tar mist: 50mg / Nm 3 , Naphthalene: 50mg / Nm 3 , Benzene: 3000mg / Nm 3 , hydrogen sulfide: 20mg / Nm 3 . The content of main impurities after purification is required: Benzene: less than 1mg / Nm 3 . Single tower processing coke oven gas volume 10000Nm 3 / h.

[0070] Control the operating pressure of the above-mentioned dry-type debenzene tower to 50kPa, the maximum operating temperature to 160°C, and the diameter of the tower to be 3.6 meters. Lay 2 layers of stainless steel wire mesh on the support of the fitted composite packing, and then instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com