In-situ chemical oxidation restoration construction method for organic contaminated soil

An in-situ chemical oxidation and organic pollution technology, which is applied in the field of soil remediation, can solve the problems of long treatment cycle of microbial remediation technology, insufficient removal of pollutants, difficult cultivation of remediation bacteria, etc., and achieve good environmental benefits and social benefits. Avoid the destruction of soil structure and achieve the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

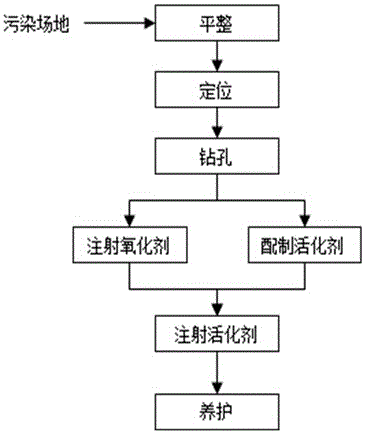

[0031] The content of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0032] see Attachment

[0033] The in-situ chemical oxidation repair construction method of organic polluted soil includes the following steps:

[0034] (1) Leveling: Clear and excavate the surface dregs in the polluted area to level the surface of the site to avoid affecting the operation of the drilling rig by the dregs on the soil surface.

[0035] (2) Positioning: According to the repair requirements, select the agent injection point and use the crawler anchor drilling rig for positioning.

[0036] (3) Drilling: Turn on the piston air compressor, the working pressure is 0.1~0.9MPa; turn on the plunger type high-pressure grouting pump, the water pump pressure is 10~40MPa, the water pump flow rate is 80-120L / min, after confirming that the nozzle is intact In the case of the rig, the drill bit starts drilling at a speed of 10~100r / min, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com