Hollow precious metal nanowire as well as preparation method and application thereof

A technology of nanowires and noble metals, which is applied in the field of hollow noble metal nanowires and its preparation and application, and can solve problems such as complicated preparation processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The present invention investigates the influence of different metal salts as precursors in the preparation process of hollow precious metal nanowires, and finds that all the metal salts provided by the present invention can be used to grow M-Ag hollow nanowires.

[0026] In some embodiments of the present invention, the M metal precursor and AgNO 3 The molar ratio is (0.1-10):1; preferably M metal precursor and AgNO 3 The molar ratio of ascorbic acid is (1-5):1; the molar ratio of ascorbic acid to M metal precursor is 5:1.

[0027] In other embodiments of the present invention, the M metal precursor includes at least one of Pt salt, Pt acid, and Pd salt; and the Pt acid is H 2 PtCl 6 ; The Pt salt is Na 2 PtCl 6 And / or K 2 PtCl; The Pd salt is K 2 PdCl 4 And / or Na 2 PdCl 4 .

[0028] In the present invention, the M metal precursor is preferably dried before use.

[0029] The present invention investigates the influence of reaction temperature and reaction time on the growth of n...

Embodiment 1

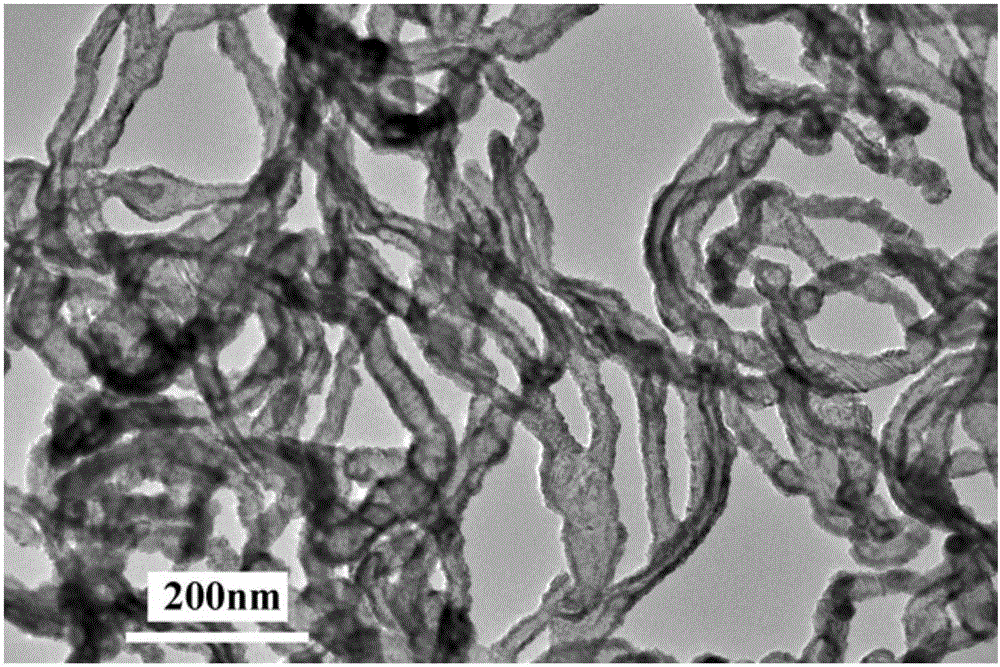

[0061] Example 1: Use H 2 PtCl 6 Used as a Pt source to prepare hollow Pt-Ag nanowires (the molar ratio of Pt to Ag is 0.12).

[0062] At room temperature, take 2.9mgH 2 PtCl 6 And 10mgAgNO 3 Dissolved in 20 mL of ethylene glycol, added 15 mg of ascorbic acid, and then added 0.4 mL of polydiallyl dimethyl ammonium chloride. After the ultrasonic dissolution was completed, the reaction was allowed to stand at room temperature for 20 hours to obtain gray-brown hollow Pt-Ag nanowires. Transfer the reaction solution in the bottle to a centrifuge tube, centrifuge for 10 minutes (10,000 revolutions / min), and disperse the sediment in water again, then centrifuge again, repeat the sedimentation and centrifugation process 3 times to remove by-products and excess solvent in the solution And the protective agent can finally obtain pure hollow Pt-Ag nanowires.

Embodiment 2

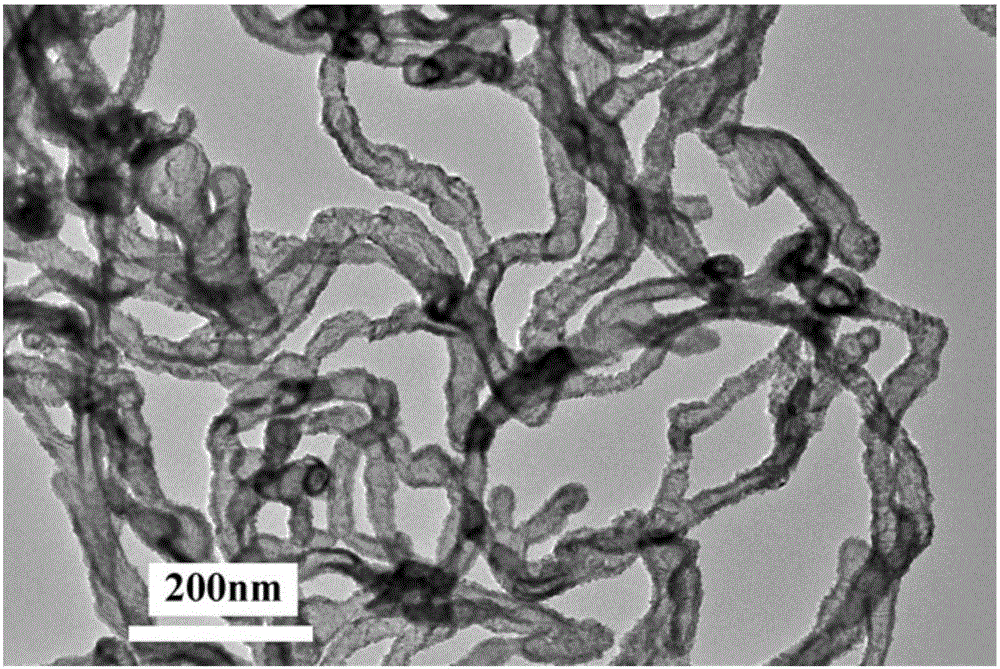

[0063] Example 2: Use Na 2 PtCl 6 Used as a Pt source to prepare hollow Pt-Ag nanowires (the molar ratio of Pt to Ag is 0.12).

[0064] At room temperature, take 3.2mgH 2 PtCl 6 And 10mgAgNO 3 Dissolved in 20 mL of ethylene glycol, added 15 mg of ascorbic acid, and then added 0.4 mL of polydiallyl dimethyl ammonium chloride. After the ultrasonic dissolution was completed, the reaction was allowed to stand at room temperature for 20 hours to obtain gray-brown hollow Pt-Ag nanowires. Transfer the reaction solution in the bottle to a centrifuge tube, centrifuge for 10 minutes (10,000 revolutions / min), and disperse the sediment in water again, then centrifuge again, repeat the sedimentation and centrifugation process 3 times to remove by-products and excess solvent in the solution And the protective agent can finally obtain pure hollow Pt-Ag nanowires.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com