Polymeric diamond saw blade and manufacturing process thereof

A technology of diamond saw blades and diamond cutter heads, which is applied in the direction of manufacturing tools, sawing machine tool manufacturing, metal sawing equipment, etc., can solve problems such as deformation, material resistance to impact, saw tooth chipping, broken teeth, etc., and achieve the goal of using Increased life, improved service life, and high cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

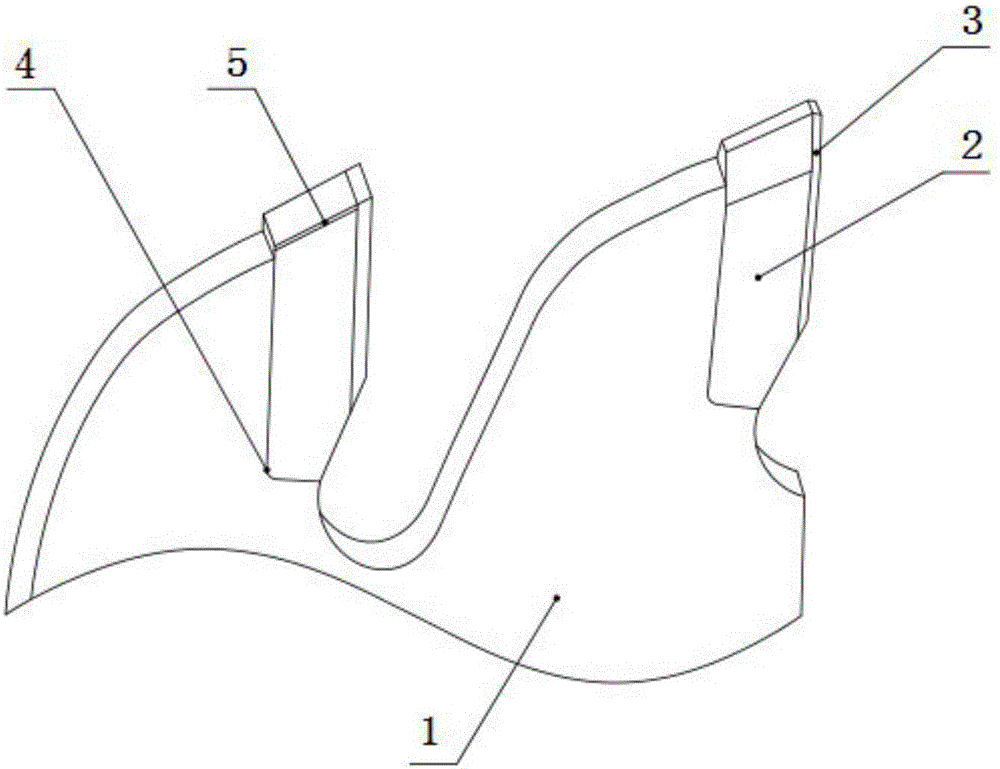

[0018] Such as figure 1 As shown, a polymeric diamond saw blade includes a saw blade body 1 and a sawtooth 2 welded on the saw blade body 1. The sawtooth 2 is provided with a polymerized diamond segment 3, and the sawtooth 2 is welded to the saw blade body 1. On the L-shaped gear holder 4, the flank surface of the serration 2 is also coated with a PVD coating 5, and the PVD coating 5 is an ALCrN hard coating, and the coating thickness is 1-4um.

[0019] The process for manufacturing the above polymerized diamond saw blades includes the following steps: step 1, pretreatment of the saw blade body; step 2, pretreatment of the polymerized diamond sawtooth; the polymerized diamond head surface of the sawtooth is polished so that the Ra value reaches 0.05, and the surface of the sawtooth The flank is ground...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com