Method for manufacturing microstructure carbide blade

A cemented carbide blade and cemented carbide technology, which are applied in the field of tool preparation and cutting processing, can solve the problems of mass production of unsuitable micro-textured tools, low equipment production efficiency, expensive process equipment, etc., and achieve high practical value and processing efficiency. High, reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to illustrate the specific implementation process of the preparation method of the present invention, the operation process and the drawings of various structures involved are explained in detail by taking YG10X tungsten steel alloy as an example in the following implementation. The implementation process provided below is only illustrative, and does not specifically limit the present invention.

[0026] The preparation method of the present invention specifically comprises the following processes:

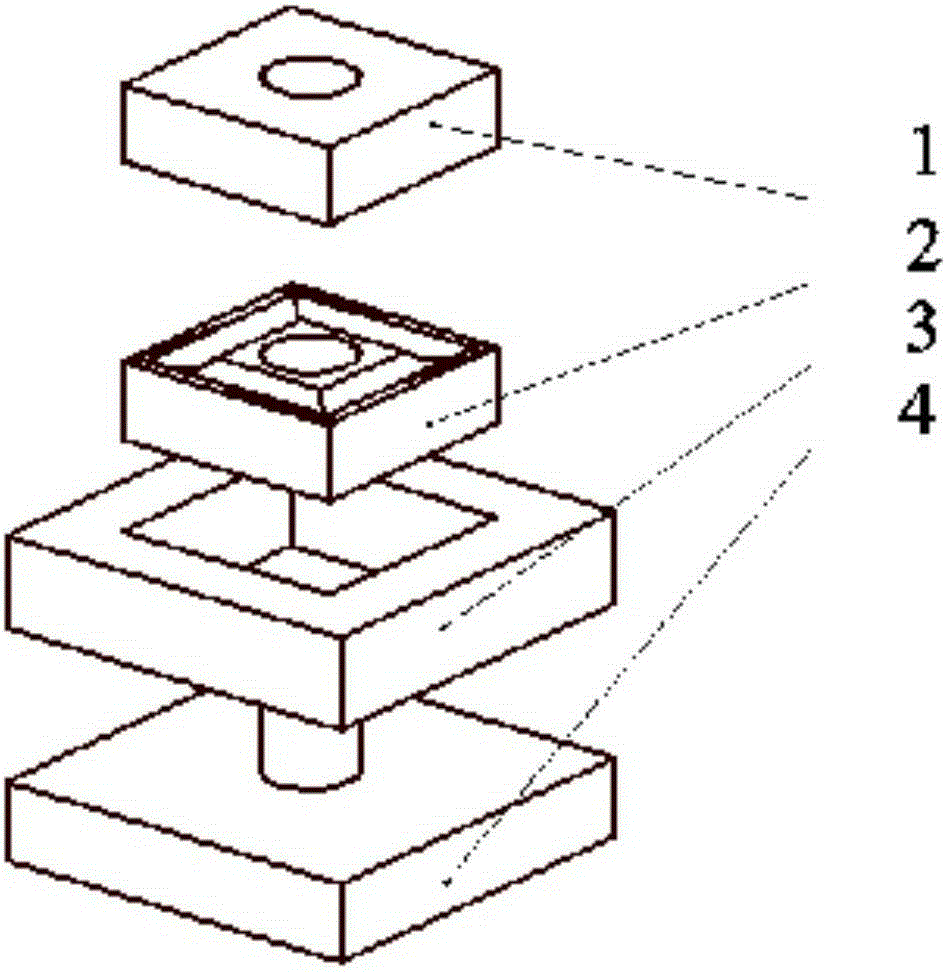

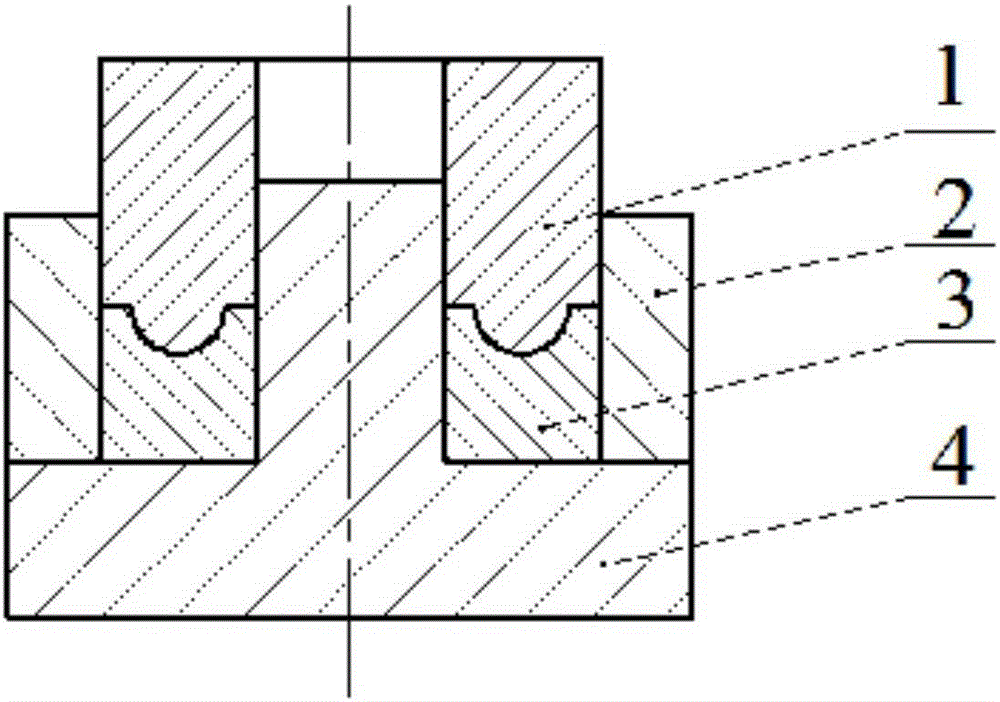

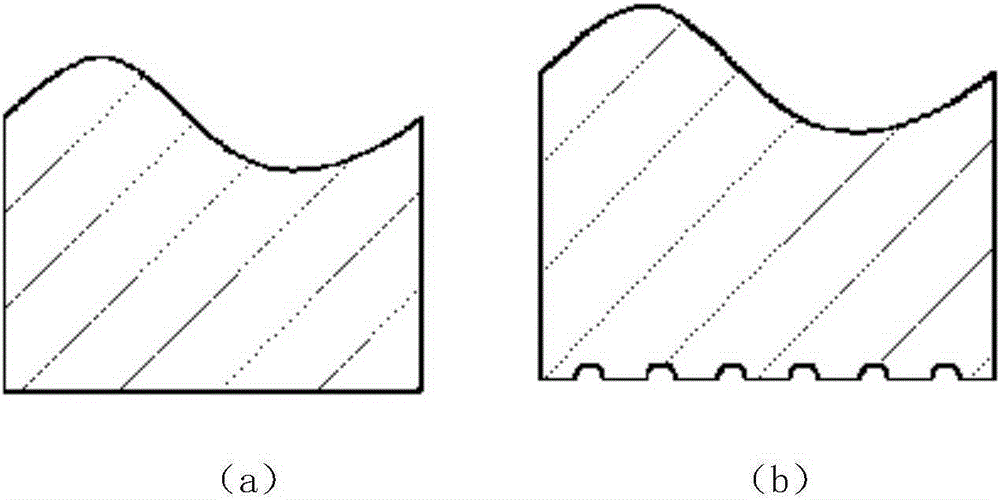

[0027] First, the cubic boron nitride grinding wheel is micro-shaped, and on the surface of the cubic boron nitride grinding wheel (such as image 3 As shown in (a), the micro-textured morphology (such as image 3 (b) shown); then use the cubic boron nitride grinding wheel after micro-shaping to grind the cemented carbide molding die to prepare a die with micro-texture topography (such as image 3 (c) shown); Then, the cemented carbide powder that is stirred even...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Arc radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com