No-damage numerical control water dissolving, polishing and removing method for KDP crystal surface micro-nano texture

A crystal surface, non-destructive technology, applied in the field of ultra-precision polishing, can solve problems such as influence and poor optical performance of crystal elements, and achieve the effect of improving surface accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner of the present invention will be described below in conjunction with the technical scheme and accompanying drawings.

[0030] The non-damaging numerical control water-dissolving polishing removal method of the micro-nano texture on the KDP crystal surface adopts the following steps:

[0031] Step 1: Utilizing the water-soluble characteristic of KDP crystals, water-containing oil-based microemulsion is selected as the polishing liquid. The water content in the polishing liquid is controlled within the range of 3%-30% according to the rough and fine polishing quality of the material and the removal rate requirements;

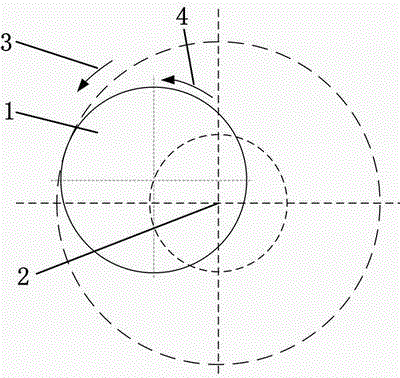

[0032] Step 2: Use a small-sized circular polishing tool with an area smaller than the KDP crystal to be processed, and a polyurethane polishing pad with low hardness is attached to the lower part of the polishing head 1;

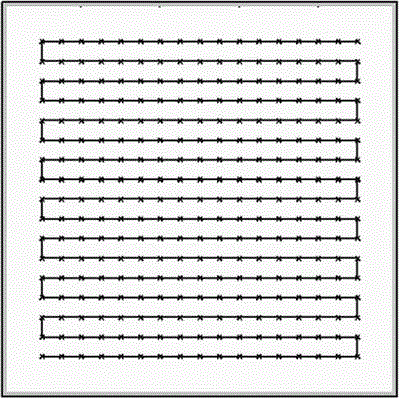

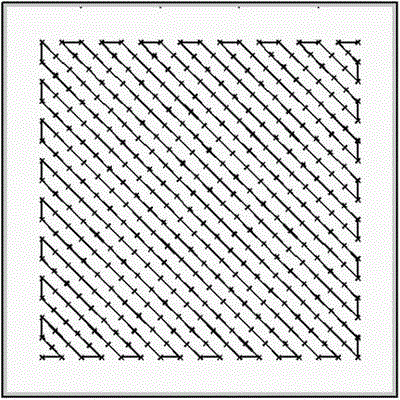

[0033] Step 3: The polishing head 1 performs planetary motion relative to the polished KDP crystal 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com