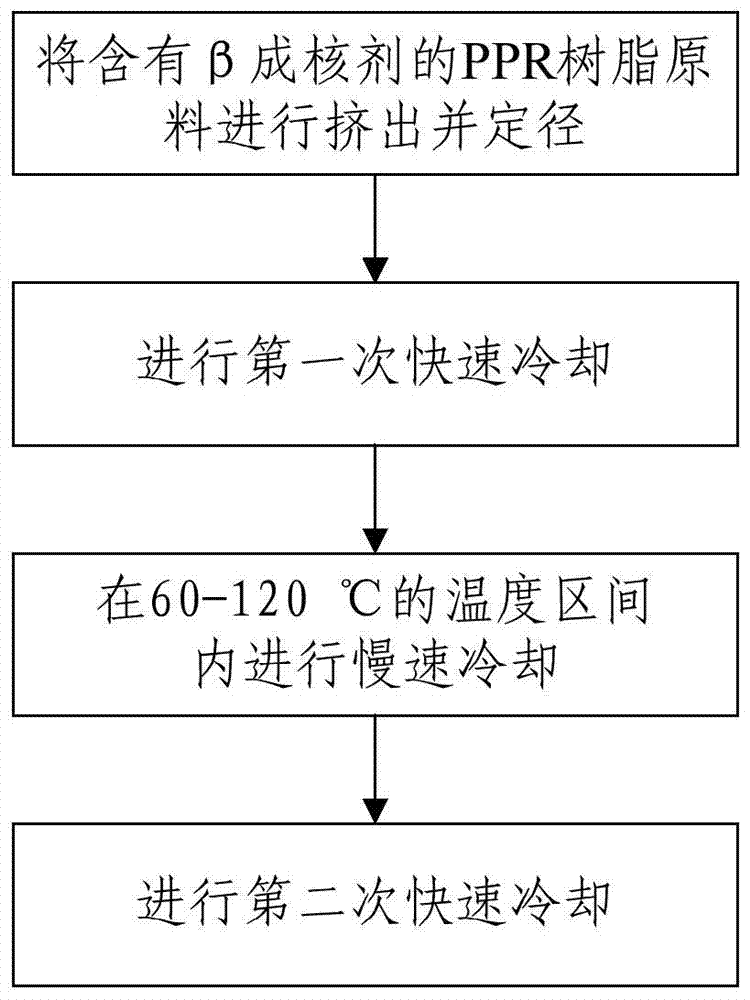

A kind of fractional crystallization method for extruding β crystal ppr pipe

A technology of fractional crystallization and β crystal form, applied in the direction of tubular articles, applications, household appliances, etc., can solve problems such as inhibiting α crystal, and achieve the effect of improving production efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

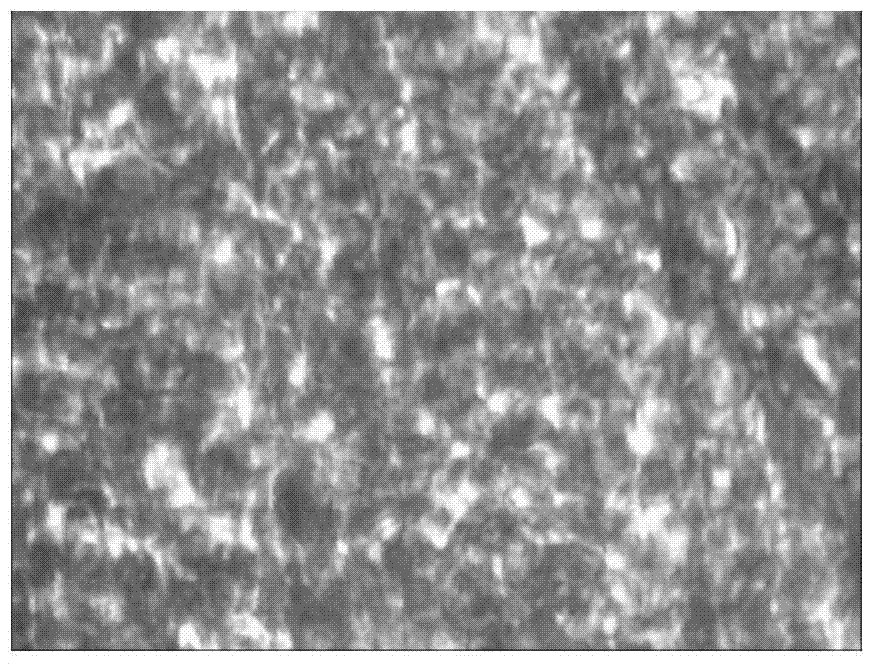

Embodiment 1

[0043] Example 1: The PPR raw material (produced by Daqing Refining and Chemical Company, brand PA14D) is heated and sheared in an extruder until the raw material is completely melted and plasticized. The barrel temperature of the extruder is 220 ° C, and the die head temperature is 230 ℃. Then the pipes are drawn into the vacuum sizing cooling water tank at a pulling speed of 10 meters per minute, the length of the water tank is 2 meters, the temperature of the cooling water tank is 20°C, and the residence time is 12s. The pipe is then passed through a continuous insulation sleeve. The length of the insulation casing is 20 meters, the temperature inside the insulation casing is maintained at 60-120°C, and the residence time is 120s. Finally, the pipe is cooled by cooling water tank, cut and packed. The length of the cooling water tank is 6 meters, the temperature of the cooling water is 20°C, and the residence time is 36s.

Embodiment 2

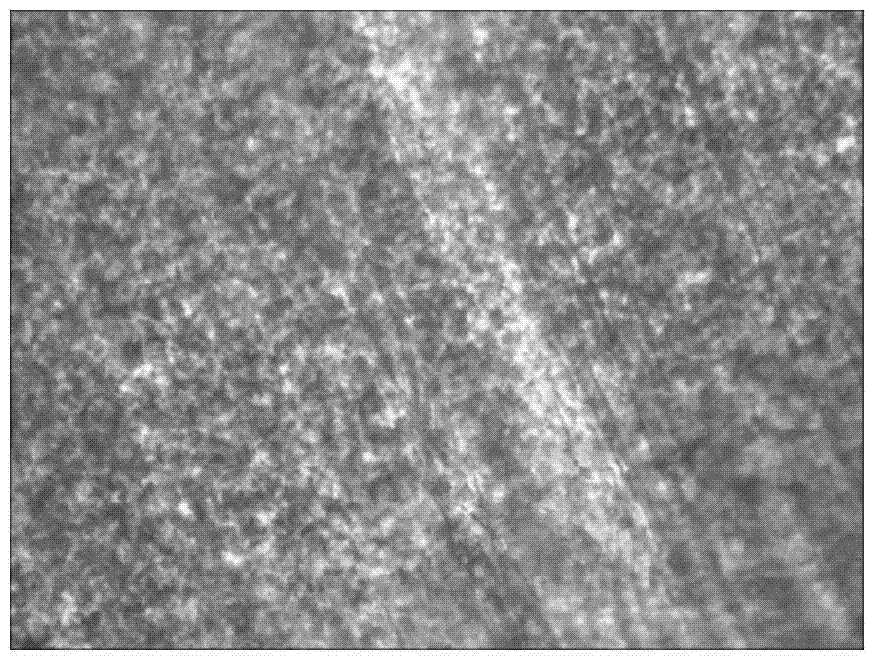

[0044] Embodiment 2: Beta ~ PPRTMRA7050 ~ GN raw material produced by Borealis is heated and sheared in an extruder until the raw material is completely melted and plasticized. The barrel temperature of the extruder is 220° C., and the die head temperature is 235°C. Then the pipes are put into the vacuum sizing cooling water tank at a pulling speed of 11 meters per minute, the length of the water tank is 2 meters, the temperature of the cooling water is 20°C, and the residence time is 11s. Then the pipe is passed through a continuous cooling water tank with a length of 26 meters, the temperature of the cooling water is 20°C, and the residence time is 142s. Finally, it is cut and packaged.

Embodiment 3

[0045] Embodiment 3: Beta ~ PPRTMRA7050 ~ GN raw material produced by Borealis is heated and sheared in an extruder until the raw material is completely melted and plasticized. The barrel temperature of the extruder is 210° C., and the die head temperature is 220°C. Then the pipes are respectively fed into the vacuum sizing cooling water tank at a traction speed of 10 meters per minute, the length of the water tank is 2 meters, the temperature of the cooling water tank is 20°C, and the residence time is 12s respectively. Then the pipe is passed through a continuous cooling water tank with a length of 26 meters, the temperature of the cooling water is 20°C, and the residence time is 156s. Finally, it is cut and packaged.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com