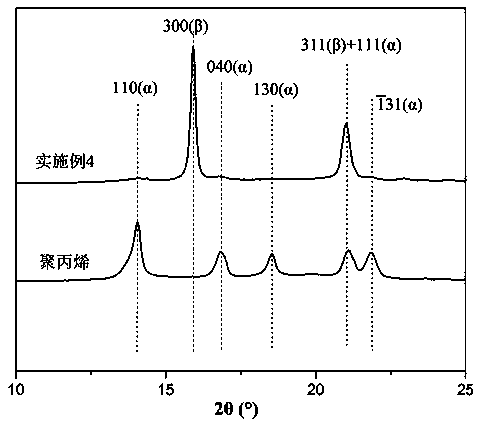

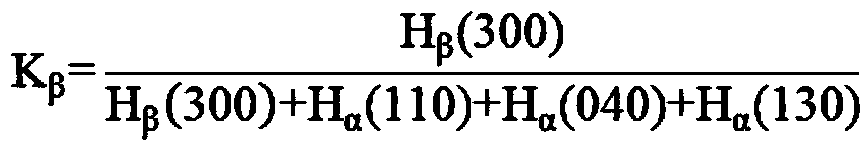

Polypropylene/liquid crystal polymer composite material with high β crystal content and preparation method

A liquid crystal polymer and composite material technology, applied in the field of polypropylene toughening and modification, can solve problems such as low β nucleation efficiency, and achieve the effects of good compatibility, excellent elongation at break, and high impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

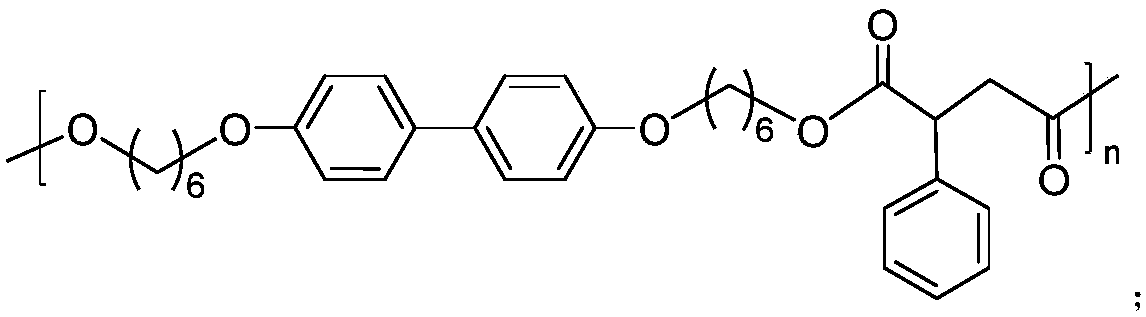

[0041] Add biphenyldioxanol and phenylsuccinic acid with a molar ratio of 1:1 into a three-necked flask, add 2‰ zinc acetate and 3‰ antimony trioxide as catalysts, heat and stir the mixture, and control the reaction temperature to 180°C and blowing nitrogen, the reaction time is 3h. After the reaction, turn off the nitrogen, start vacuuming, control the reaction temperature to rise to 200°C, the vacuum degree is less than 60Pa, the reaction time is 3.5h, and finally cool to obtain the liquid crystal polymer β nucleating agent LCP-NA (polymerization degree 90, molecular weight 50000 ).

[0042] The formula is: 400g of isotactic polypropylene (Sinopec PPH-T03, MFR=3.0g / 10min), 0.4g of liquid crystal polymer beta nucleating agent (LCP-NA), 0.4g of antioxidant 1010 (BASF, Germany).

[0043] Dry iPP and LCP-NA in a vacuum oven for 8 hours for later use. Select the appropriate screw temperature, rotation speed and aspect ratio, melt and blend the dry isotactic polypropylene, β-nuc...

Embodiment 2

[0045]Add biphenyldioxanol and phenylsuccinic acid with a molar ratio of 1:1 into a three-necked flask, add 2‰ zinc acetate and 3‰ antimony trioxide as catalysts, heat and stir the mixture, and control the reaction temperature to 180°C and blowing nitrogen, the reaction time is 3h. After the reaction, turn off the nitrogen, start vacuuming, control the reaction temperature to rise to 200°C, the vacuum degree is less than 60Pa, the reaction time is 3.5h, and finally cool to obtain the liquid crystal polymer β nucleating agent LCP-NA (polymerization degree 90, molecular weight 50000 ).

[0046] The formula is: 400g of isotactic polypropylene (Sinopec PPH-T03, MFR=3.0g / 10min), 8g of liquid crystal polymer beta nucleating agent (LCP-NA), 1.0g of antioxidant 1010 (BASF, Germany).

[0047] Dry iPP and LCP-NA in a vacuum oven for 8 hours for later use. Select the appropriate screw temperature, rotation speed and aspect ratio, melt and blend the dry isotactic polypropylene, β-nuclea...

Embodiment 3

[0049] Add biphenyldioxanol and phenylsuccinic acid with a molar ratio of 1:1 into a three-necked flask, add 2‰ zinc acetate and 3‰ antimony trioxide as catalysts, heat and stir the mixture, and control the reaction temperature to 180°C and blowing nitrogen, the reaction time is 3h. After the reaction, turn off the nitrogen, start vacuuming, control the reaction temperature to rise to 200°C, the vacuum degree is less than 60Pa, the reaction time is 3.5h, and finally cool to obtain the liquid crystal polymer β nucleating agent LCP-NA (polymerization degree 90, molecular weight 50000 ).

[0050] The formula is: 400g of isotactic polypropylene (Sinopec PPH-T03, MFR=3.0g / 10min), 16g of liquid crystal polymer beta nucleating agent (LCP-NA), 1.2g of antioxidant 1010 (BASF, Germany).

[0051] Dry iPP and LCP-NA in a vacuum oven for 8 hours for later use. Select the appropriate screw temperature, rotation speed and aspect ratio, melt and blend the dry isotactic polypropylene, β-nucl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com