Production method of polypropylene crystal form design toughened modified optical cable loose tube

A technology of toughening modification and production method, applied in the field of material modification and optical cable production, can solve the problems of poor impact performance, heat resistance can not meet processing requirements, poor toughness of PP sleeve, etc., to achieve high heat resistance , The effect of preventing casing tie marks, good impact resistance and casing bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

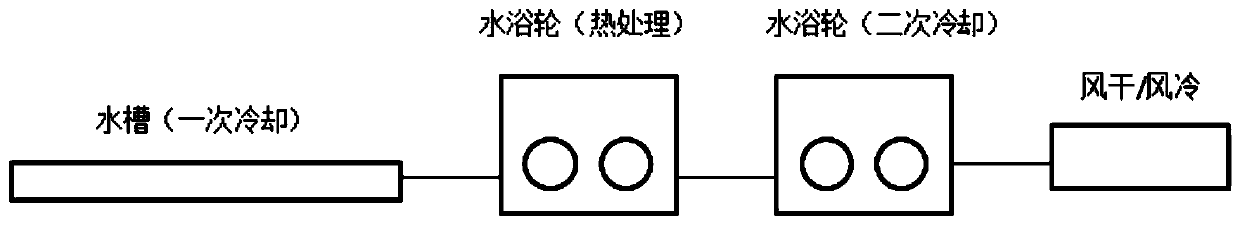

[0026] The special modified PP for secondary coating (produced by Jiangyin Aikesen, brand GPP3030), color masterbatch (produced by Yangzhou Jinsen, blue color masterbatch, brand 703, the addition amount is 2wt%) is melted and produced by a single-screw extruder 2.3 / 1.6-12B1 specification loose tube, the temperature of the four zones of the extruder body is 190°C, 200°C, 210°C, 220°C, and the temperature of the three zones of the head is 220°C, 225°C, 230°C . After drawing the tube and threading the fiber, the high-speed production speed is 200m / min and it enters the cooling water tank, the length of the water tank is 4m, the water temperature is 35°C, and then it enters the heat treatment water bath pulley, winding 5 times, the water temperature is 80°C, and enters the water bath pulley cooling after heat treatment , Winding 5 full circles, the cooling temperature is 35°C, and then enters the air-cooled drying equipment, the cooling temperature is 20°C, and then enters the wi...

Embodiment 2

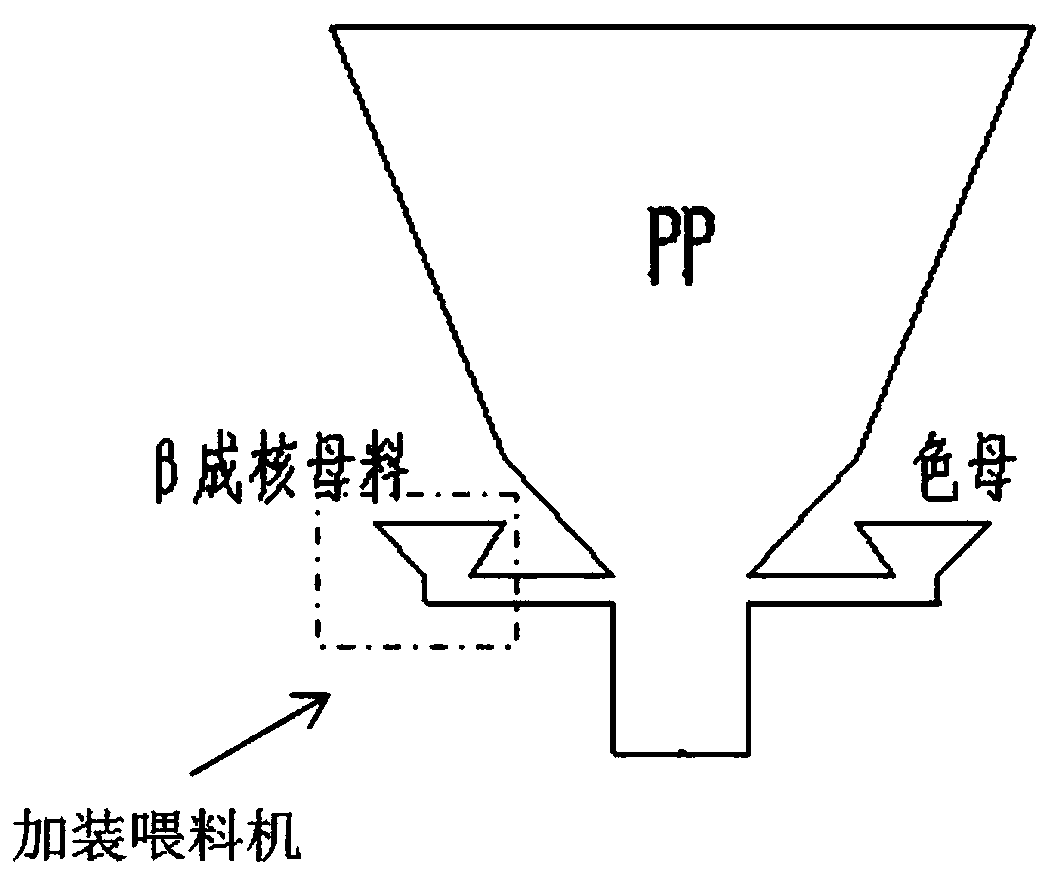

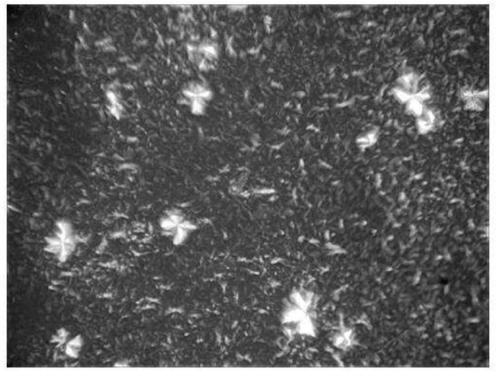

[0028] Modified PP for secondary plastic coating (produced by Jiangyin Aikesen, brand GPP3030), color masterbatch (produced by Yangzhou Jinsen, blue color masterbatch, brand 703), β-nucleating masterbatch (Nanjing Chengkuan Trading Co., Ltd., brand : MNT-C, addition amount 1wt%), the main body of the β-nucleating masterbatch is a mixture of 30wt% carboxylate nucleating agent and PP, and the three are melted through a single-screw extruder to produce 2.3 / 1.6-12B1 specification pine As for the casing, the temperature of the body of the extruder is 190°C, 200°C, 210°C, and 220°C, and the temperature of the head is 220°C, 225°C, and 230°C. After drawing the tube and threading the fiber, the high-speed production speed is 200m / min and it enters the cooling water tank. The length of the water tank is 4m, and the water temperature is 35°C. Then it enters the heat treatment water bath wheel puller, wraps 5 times, and the water temperature is 80°C. After heat treatment, it enters the wa...

Embodiment 3

[0030] Modified PP for secondary plastic coating (produced by Jiangyin Aikesen, brand GPP3030), color masterbatch (produced by Yangzhou Jinsen, blue color masterbatch, brand 703), β-nucleating masterbatch (Nanjing Chengkuan Trading Co., Ltd., brand : MNT-C, addition amount 1wt%), the main body of the β-nucleating masterbatch is a mixture of 30wt% carboxylate nucleating agent and PP, and the three are melted through a single-screw extruder to produce 2.3 / 1.6-12B1 specification pine As for the casing, the temperature of the body of the extruder is 190°C, 200°C, 210°C, and 220°C, and the temperature of the head is 220°C, 225°C, and 230°C. After drawing the tube and threading the fiber, the high-speed production speed is 200m / min and enters the cooling water tank, the length of the water tank is 4m, the water temperature is 35°C, and then enters the heat treatment water bath pulley, winding 5 times, the water temperature is 90°C, and enters the water bath pulley after heat treatmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com