A nano-diamond film with si-v luminescence and its controllable preparation method

A nano-diamond and polycrystalline diamond technology, which is applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems that the Si-V luminescence performance of thin films is difficult to control and does not have Si-V luminescence performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

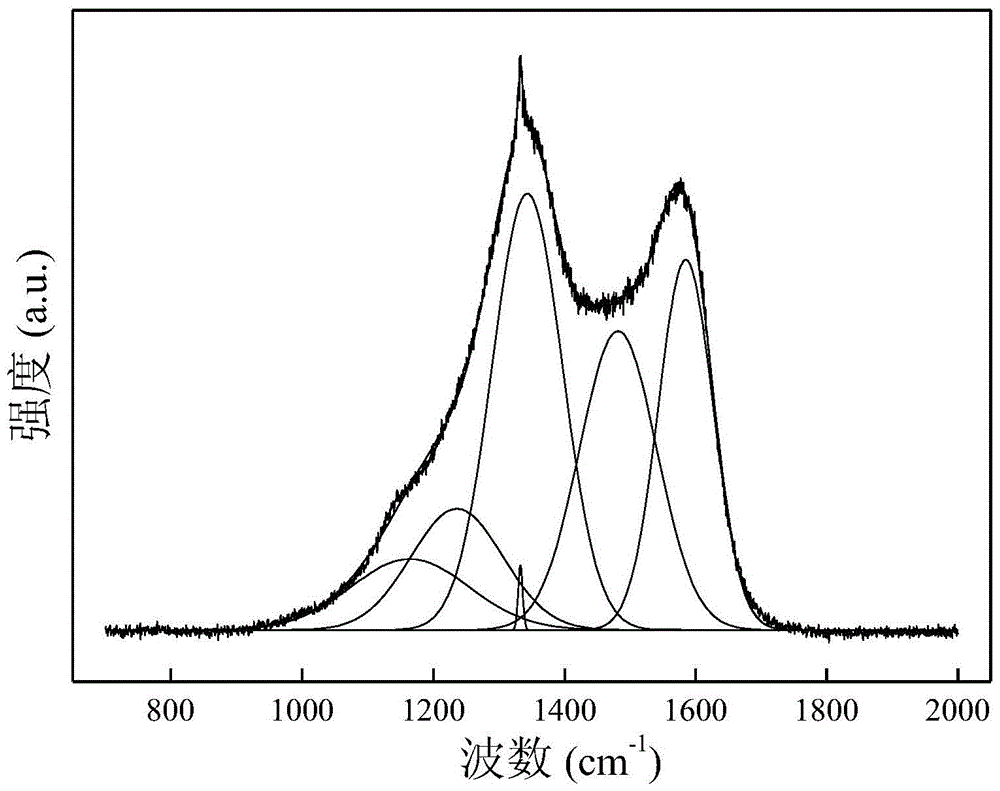

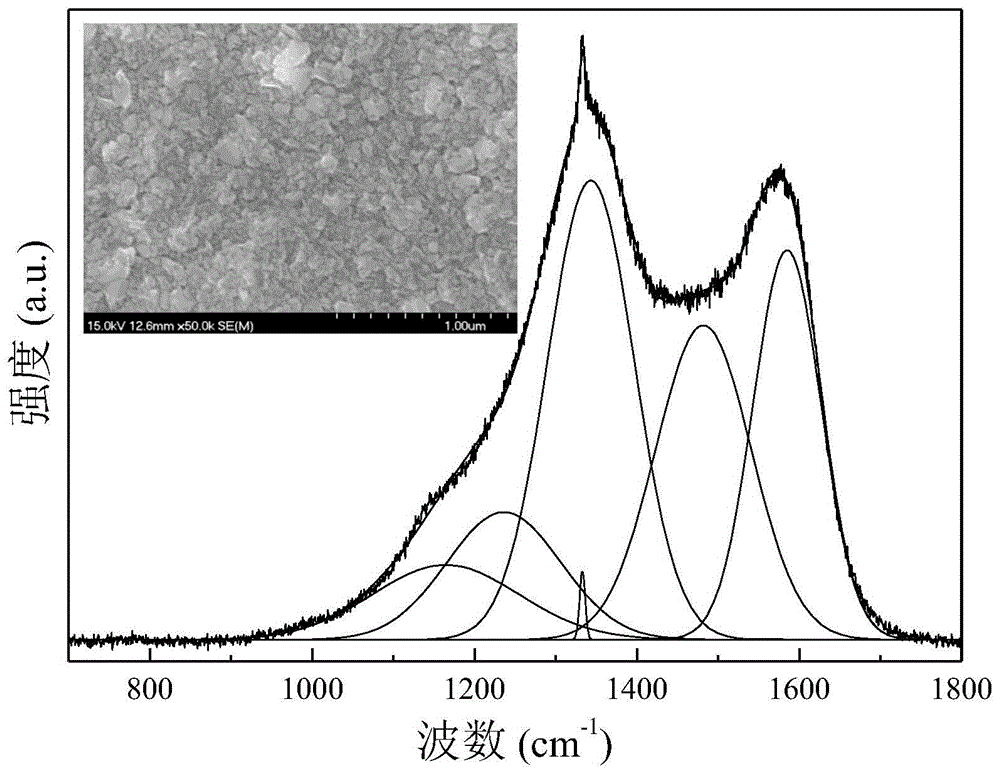

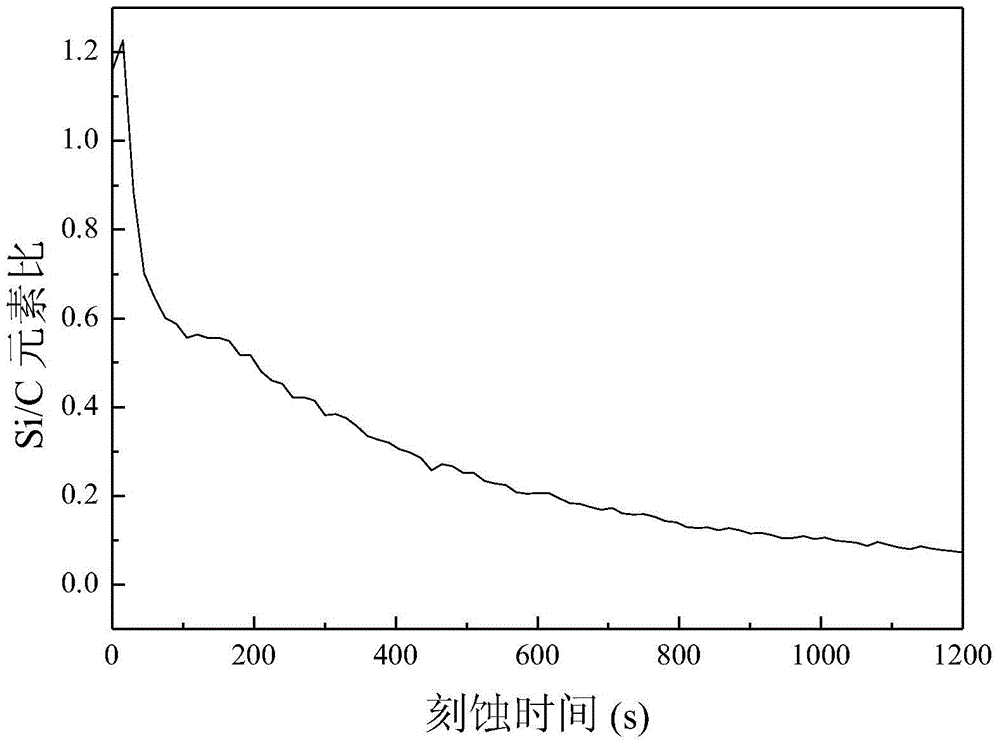

[0023] Polish the polycrystalline diamond substrate with nano-sized diamond powder for about 15 minutes. The polished polycrystalline diamond substrate was ultrasonically oscillated in a diamond micropowder-acetone suspension for 2 hours, then ultrasonically cleaned with deionized water and acetone, and dried, and then used as a substrate for growing a nano-diamond film. Using hot wire chemical vapor deposition (chemical vapor deposition equipment purchased from Shanghai Jiaoyou Diamond Coating Co., Ltd., model JUHF CVD001), using acetone as the carbon source, acetone was brought into the reaction chamber by hydrogen bubbling, and the reaction chamber The temperature is controlled at 600-700° C., the preparation time is 4 hours, and a nano-diamond film with a thickness of 4-6 μm is prepared. Using a 100keV isotope separator, the injection energy is 80keV, and the nano-diamond film is subjected to 10 14 cm -2 silicon ion implantation treatment to obtain silicon ion implanted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com