A silicon additive based on crystalline silicon diamond wire cutting waste and its preparation method

A technology of diamond wire cutting and silicon additives, which is applied in the field of secondary resource utilization, can solve problems such as potential safety hazards, fire hazards, and increased production costs, and achieve the effects of reducing energy consumption and production costs, fast melting speed, and realizing reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

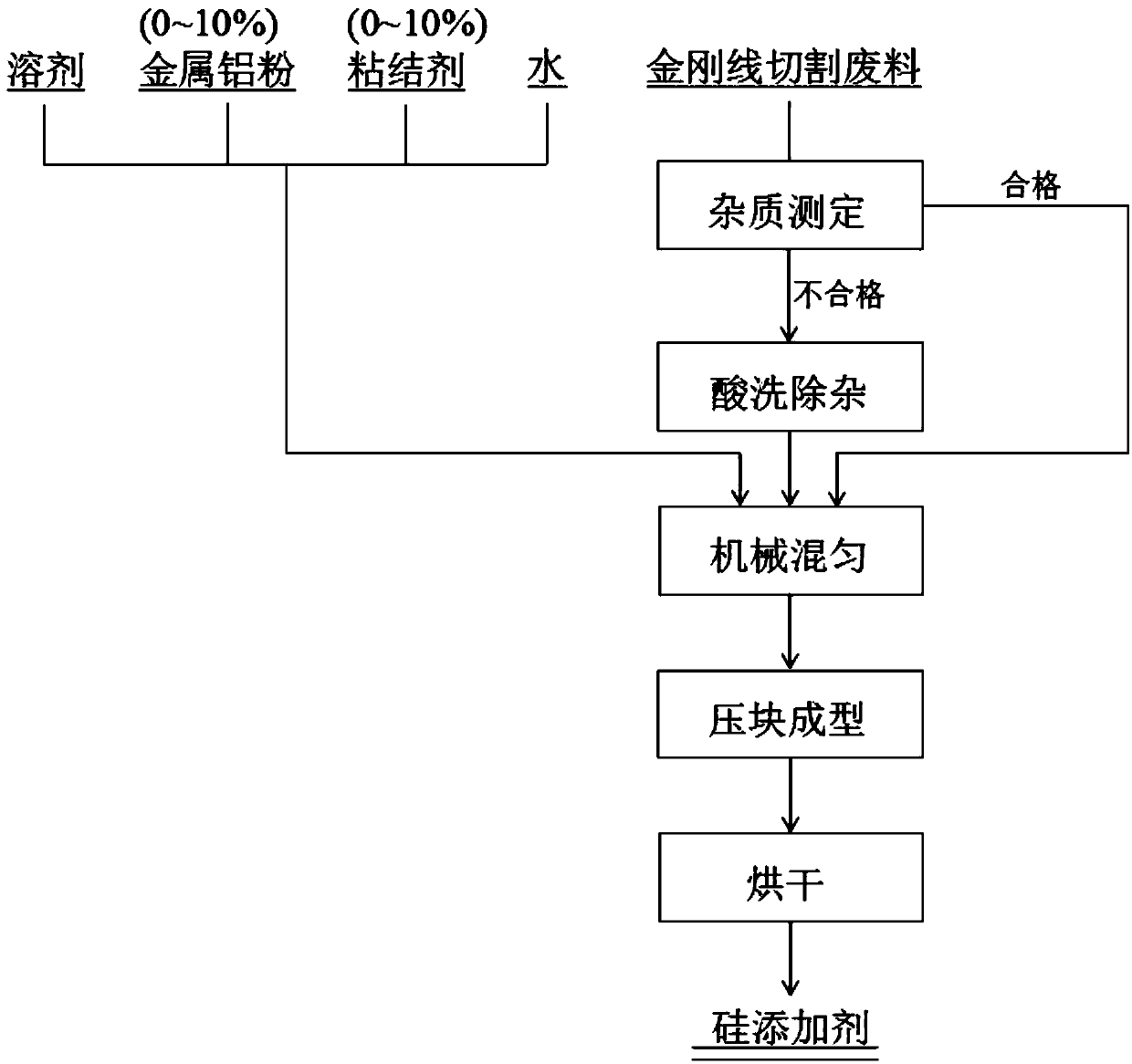

[0025] The method for preparing a kind of silicon additive for aluminum alloy using diamond wire cutting waste of crystalline silicon as raw material of the present invention is carried out in the following steps:

[0026] (1) Weigh a certain amount of crystalline silicon diamond wire cutting waste, solvent and binder, wherein, by weight percentage, the solvent accounts for 30%, the binder accounts for 5%, and the balance is cutting waste. After that, add water accounting for 10% of the total amount of material, and mix evenly in a mixer after batching.

[0027] (2) The mixed material is pressed into blocks by cold isostatic pressing, each block weighs 500-4000g, the pressure used for forming is 120MPa, and the holding time is 300s. The cake obtained after drying is crystal-based Silicon additives for silicon diamond wire sawing scrap.

Embodiment 2

[0029] The method for preparing a kind of silicon additive for aluminum alloy using diamond wire cutting waste of crystalline silicon as raw material of the present invention is carried out in the following steps:

[0030] (1) take by weighing the diamond wire cutting scrap of a certain amount of crystalline silicon, solvent, binding agent and metal aluminum powder, wherein, by weight percentage, solvent accounts for 5%, and aluminum powder accounts for 10% and the particle size of adding aluminum powder is 0.8mm, the margin is cutting waste. After that, add water accounting for 20% of the total amount of material, and mix evenly in a mixer after batching.

[0031] (2) The mixed material is pressed into blocks by cold isostatic pressing. The weight of each block is 500-4000g. The pressure used for forming is 600MPa, and the holding time is 60s. The cake obtained after drying is crystal-based Silicon additives for silicon diamond wire sawing scrap.

Embodiment 3

[0033] The method for preparing a kind of silicon additive for aluminum alloy using diamond wire cutting waste of crystalline silicon as raw material of the present invention is carried out in the following steps:

[0034] (1) Take by weighing a certain amount of crystalline silicon diamond wire cutting waste, solvent, binding agent and metal aluminum powder, wherein, by weight percentage, solvent accounts for 20%, binding agent accounts for 10%, and aluminum powder accounts for 5% And the particle size of the added aluminum powder is 0.2mm, and the remainder is cutting waste. Add water accounting for 5% of the total amount of material afterwards, and mix evenly in a mixer after batching.

[0035] (2) The mixed material is pressed into blocks by cold isostatic pressing, each block weighs 500-4000g, the pressure used for forming is 200MPa, and the holding time is 150s. The cake obtained after drying is crystal-based Silicon additives for silicon diamond wire sawing scrap.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com