Method for preparing chlorinated titanium-rich material by taking Panxi titanium concentrate and titanium tetrachloride dust collection slag as raw materials

A technology for titanium tetrachloride and dust collection slag, applied in flotation, solid separation and other directions, can solve problems such as difficulty in preparing chlorinated titanium-rich materials, and achieve the effects of reducing smelting difficulty, smelting cost, and reducing dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

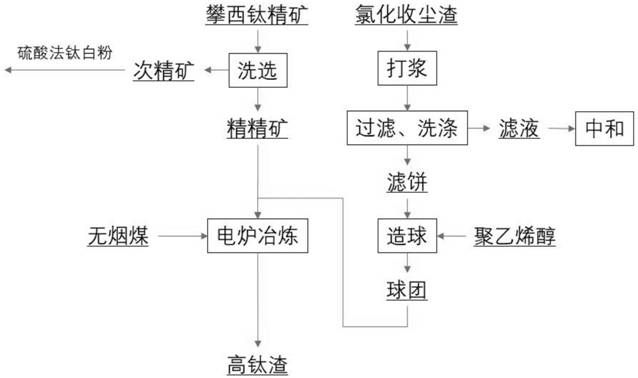

Image

Examples

Embodiment 1

[0025] Prepare titanium chloride rich material according to the following method:

[0026] (1) A Panxi high-silicon calcium magnesium titanium concentrate (TiO 2 47.47%, SiO 2 2.67%, CaO 0.85%, MgO5.10%), fine grinding first, and then adding silicon-inhibiting flotation agents for 4 times of flotation to obtain concentrate: TiO 2 50.13%, SiO 2 0.70%, CaO 0.20%, MgO 4.76%; secondary concentrate contains TiO 2 46.50%, SiO 2 3.60%, CaO 1.20% or so ordinary titanium concentrate; the silicon-inhibiting flotation agent is composed of the following components in mass fractions: 100 parts of collectors, 32 parts of inhibitors, and 30 parts of regulators. The mass ratio of Panxi titanium concentrate to silicon-inhibiting flotation agent is 1000:1.

[0027] (2) After beating the chlorinated dust collection slag with a hydrochloric acid solution with a mass concentration of 0.1%, press-filter and wash the slurry to obtain a filter cake, and the measured filter cake components are sh...

Embodiment 2

[0039] Prepare titanium chloride rich material according to the following method:

[0040] (1) A Panxi high-silicon calcium magnesium titanium concentrate (TiO 2 47.47%, SiO 2 2.67%, CaO 0.85%, MgO5.10%), fine grinding first, and then adding silicon-inhibiting flotation agents for 4 times of flotation to obtain concentrate: TiO 2 50.13%, SiO 2 0.70%, CaO 0.20%, MgO 4.76%; secondary concentrate contains TiO 2 46.50%, SiO 2 3.60%, CaO 1.20% or so ordinary titanium concentrate; the silicon-inhibiting flotation agent is composed of the following components in mass fractions: 100 parts of collectors, 32 parts of inhibitors, 30 parts of regulators; The mass ratio of titanium concentrate to silicon-inhibiting flotation agent is 1000:1.

[0041] (2) After beating the chlorinated dust collection slag with a hydrochloric acid solution with a mass concentration of 0.5%, the slurry is press-filtered and washed to obtain a filter cake, and the measured filter cake components are shown...

Embodiment 3

[0053] Prepare titanium chloride rich material according to the following method:

[0054] (1) A Panxi high-silicon calcium magnesium titanium concentrate (TiO 2 47.47%, SiO 2 2.67%, CaO 0.85%, MgO5.10%), fine grinding first, and then adding silicon-inhibiting flotation agents for 4 times of flotation to obtain concentrate: TiO 2 50.13%, SiO 2 0.70%, CaO 0.20%, MgO 4.76%; secondary concentrate contains TiO 2 46.50%, SiO 2 3.60%, CaO 1.20% or so ordinary titanium concentrate; the silicon-inhibiting flotation agent is composed of the following components in mass fractions: 100 parts of collectors, 32 parts of inhibitors, 30 parts of regulators; The mass ratio of titanium concentrate to silicon-inhibiting flotation agent is 1000:1.

[0055] (2) After beating the chlorinated dust collection slag with a hydrochloric acid solution with a mass concentration of 1%, the slurry is press-filtered and washed to obtain a filter cake, and the measured filter cake components are shown i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com