Simulating and evaluating method for acidification of carbonate heavy-oil reservoir

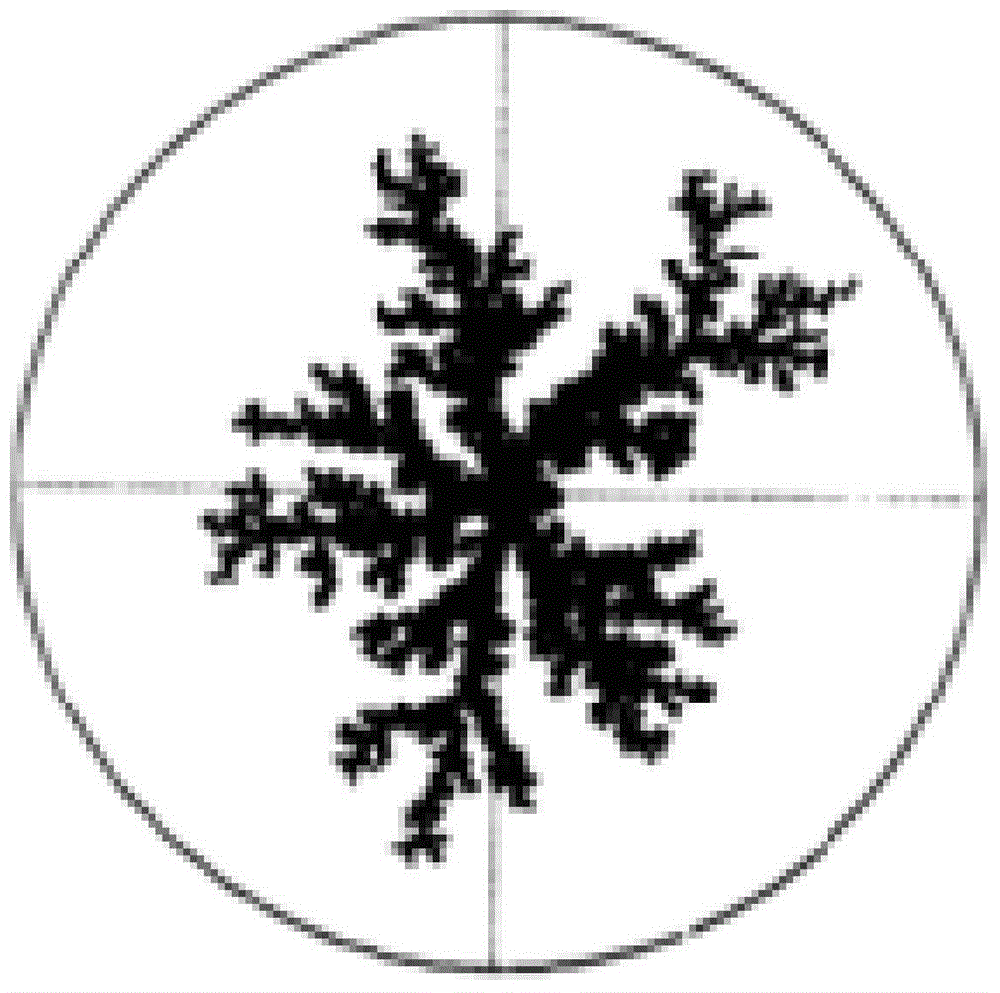

A technology for heavy oil reservoirs and carbonate rocks, which is used in earth-moving drilling, fluid production, wellbore/well components, etc., can solve the problem that the morphological characteristics and differences of acid-etched holes cannot be determined, and cannot reflect the properties of formation fluids. Problems such as the effect of acid etching hole formation and expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0054] The experimental object is the core of the Shirinish heavy oil reservoir in the Zagros structural belt in the Middle East. The temperature of the reservoir is 50°C, and the viscosity of the heavy oil is 500-2000mPa.s under the formation conditions. The core of the Shirinish section is taken and processed into several cylindrical pieces. Rock core samples, according to the simulation process of this patent method, carry out the following operations:

[0055] (1) Determination of relevant relevant parameters, the results are shown in Table 1 below:

[0056] Table 1

[0057]

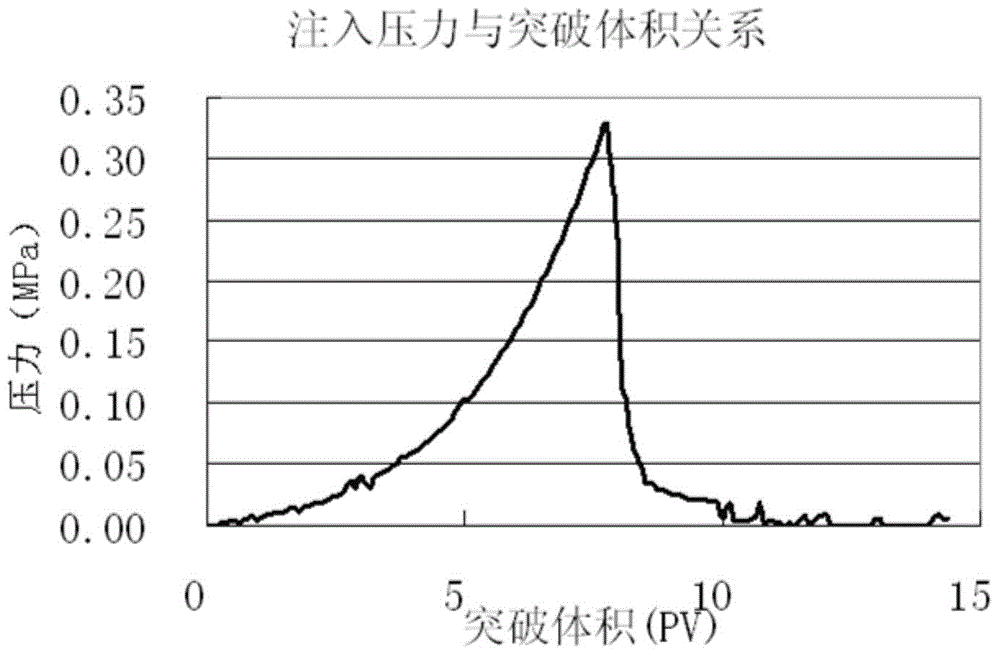

[0058] (2) Wash the core with oil, measure the pore volume, calculate the porosity, and then inject 2% KCl solution at the injection rate to measure the permeability. The results are shown in Table 2. Heat the heavy oil so that its viscosity is lower than 10mpa.s, use the heavy oil to displace the core, wait for the heavy oil to return from the outlet, and end after the flow is stable, lower the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com