Overdamped vibration isolator capable of generating negative stiffness through inclined magnets

A super-damping and vibration isolator technology, applied in the direction of shock absorbers, shock absorber-spring combinations, shock absorbers, etc., can solve the problems of reduced measurement accuracy of instruments, shortened service life of structures, and reduced launch accuracy. The effect of widening the vibration isolation frequency band, facilitating adjustment and replacement, and suppressing vibration response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

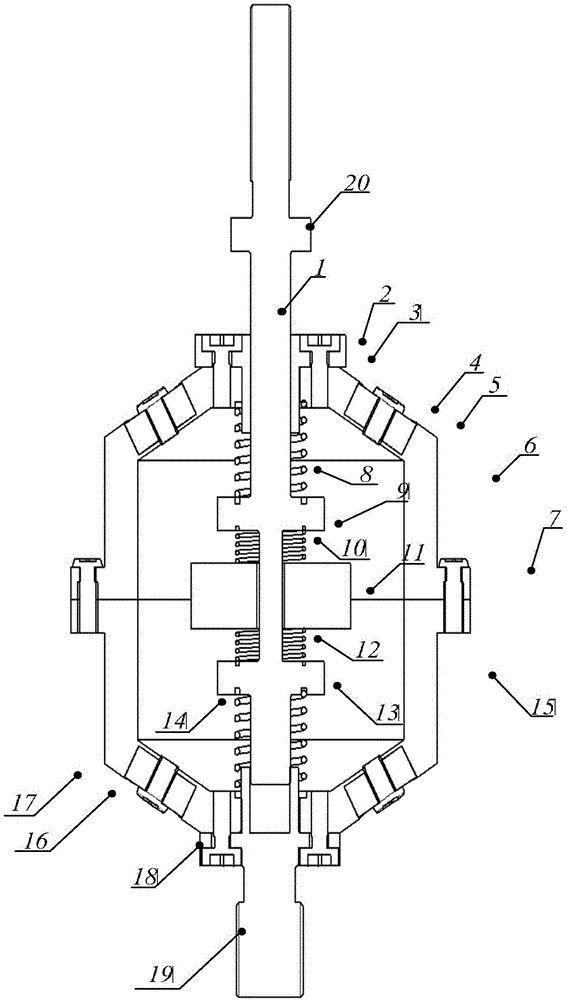

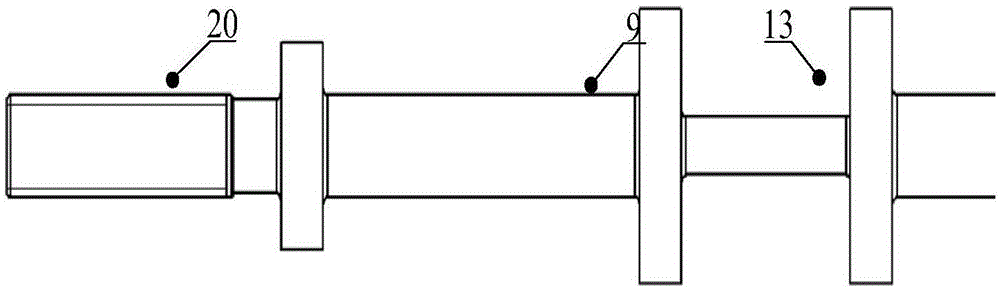

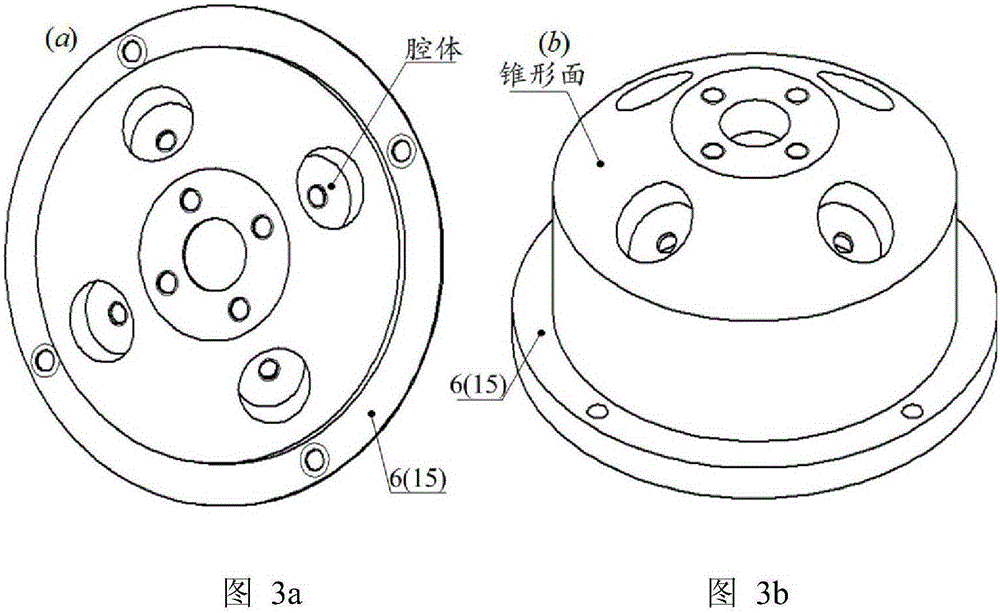

[0026] Such as figure 1 , figure 2 , shown in Fig. 3 and Fig. 4, the present invention is a kind of super-damping vibration isolator that adopts inclined magnet to produce negative stiffness, comprises the central shaft with first boss 20, second boss 9, third boss 13 1. A threaded segment is provided on the upper shaft section of the first boss 20; a sliding bearing 3 is arranged axially between the first boss 20 and the second boss 9; the sliding bearing 3 passes through The first fastening bolt 2 is fastened to the upper end surface of the upper end cover 6; four cavities are arranged on the conical surface of the upper end cover 6; the first inclined annular permanent magnet 5 is installed on the upper end cover 6 in the cavity on the conical surface; the upper end cover 6 and the first inclined annular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com