Boiler water level detecting device and control method thereof

A technology of water level detection and control method, applied in the field of sensors, can solve the problems of inability to find sensor faults and low detection accuracy, and achieve the effects of good stability and reliability, high detection accuracy and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

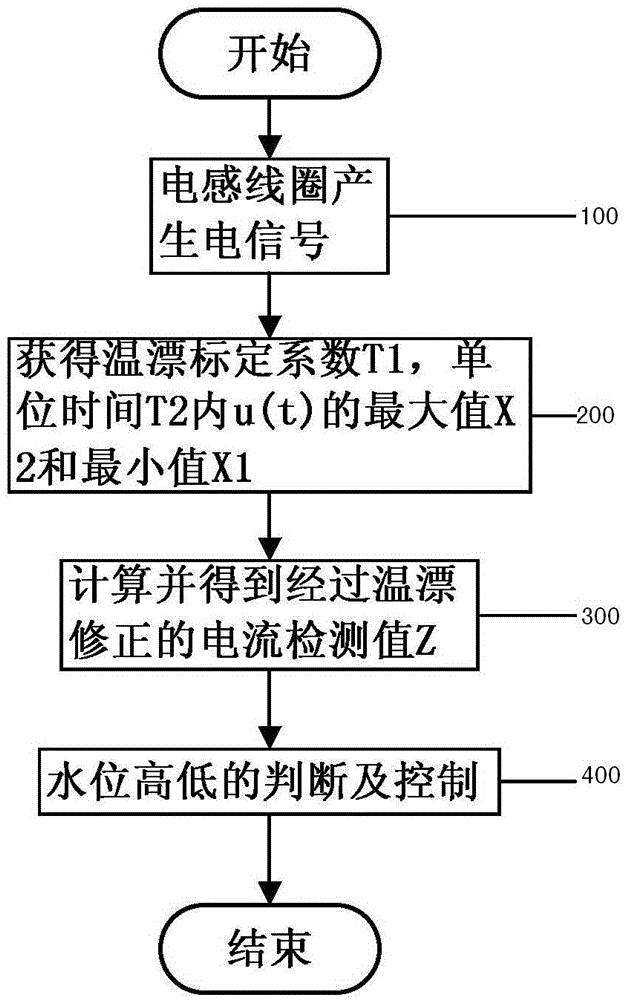

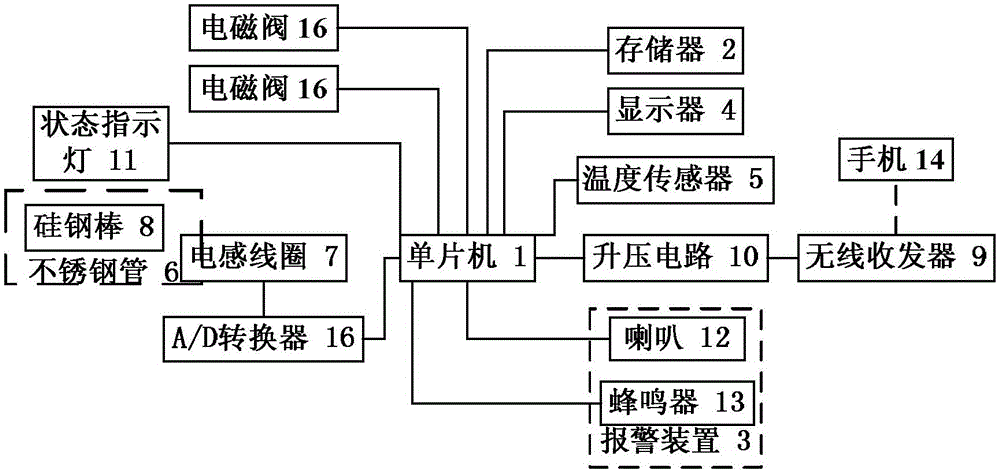

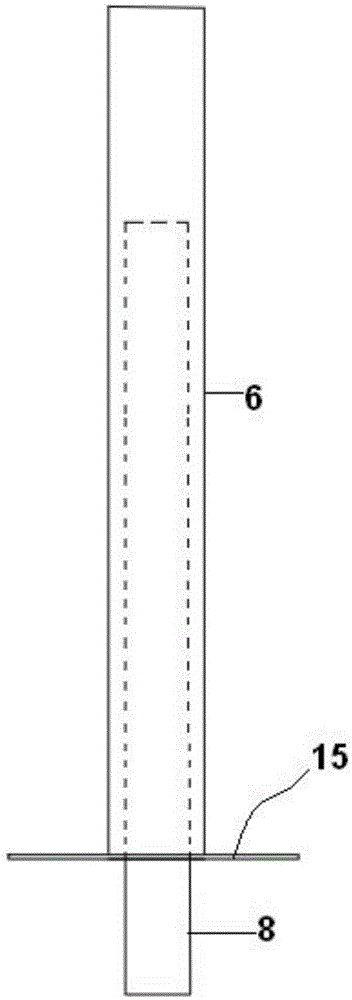

[0056] Such as figure 1 The shown embodiment is a boiler water level detection device. The boiler is provided with a water inlet pipe and an outlet pipe; it includes a housing, a single-chip microcomputer 1, an A / D converter 16 and a memory 2 arranged in the housing, and a housing An alarm device 3 and a display 4 on the body, a vertical stainless steel tube 6 with an open lower end in the boiler, an inductance coil 7 on the stainless steel tube; a silicon steel rod 8 that can move up and down relative to the stainless steel tube is arranged in the stainless steel tube , the float located at the lower end of the silicon steel rod and the guide cylinder for accommodating the lower part of the silicon steel rod and the float. Sensor 5; the lower end of the stainless steel pipe is provided with an extended edge 15 extending horizontally outwards, and the extended edge is sealed and connected with the inner wall of the boiler; an electromagnetic valve 16 is arranged on the water i...

Embodiment 2

[0076] Embodiment 2 includes all structures and steps in Embodiment 1. After the working time of the induction coil exceeds 5 minutes, step 400 of Embodiment 1 is replaced by the following steps:

[0077] The single-chip microcomputer reads the Z stored in the memory before the current time T2 time, and calculates and obtains the average value Z' of the Z at the current time and the Z before the T2 time,

[0078] When Z'≥W2, the solenoid valve of the water outlet pipe controlled by the single-chip microcomputer is opened for 5 minutes and then closed, and the display shows water information during the water intake process;

[0079] When Z′≤W1, the solenoid valve of the water inlet pipe controlled by the single-chip microcomputer is opened for 15 minutes and then closed, and the display shows the water inlet information during the water inlet process;

[0080] When W10 Increase the value of T2, return to step 200.

Embodiment 3

[0082] Embodiment 3 includes all structures and step parts in Embodiment 1, and also includes the following steps between steps 110 and 200 of Embodiment 1:

[0083] (7-1) The initial value of j is set to 1 in the memory, the initial value of i is 1, and the fault threshold E is set;

[0084] (7-2) The single-chip computer calculates the local maximum value of u(t) and obtains the upper envelope u through cubic spline interpolation up (t);

[0085] (7-3) Calculate the local minimum of the signal u(t) and obtain the lower envelope u through cubic spline interpolation low (t);

[0086] (7-4) Define the average envelope m 1 (t)=[u up (t)+u low (t)] / 2;

[0087] (7-5) Using the formula h j (t)=u(t)-m j (t) Calculate the difference h j (t);

[0088] (7-6) if h j (t) does not meet the IMF screening stop condition, make u(t)=h j (t), the value of j increases by 1, and returns to step (7-2) for h j (t) continue to decompose; when h j (t) Satisfies the IMF screening stop c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com