Test method for detonation velocity of nonel with defect

A test method and detonation tube technology, applied in the direction of measuring devices, material analysis through optical means, instruments, etc., can solve the problems of drug powder falling off the inner wall of the detonation tube, explosion rejection, drug breakage, etc., to achieve accurate measurement and reduce difficulty , the effect of reducing the amount of calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

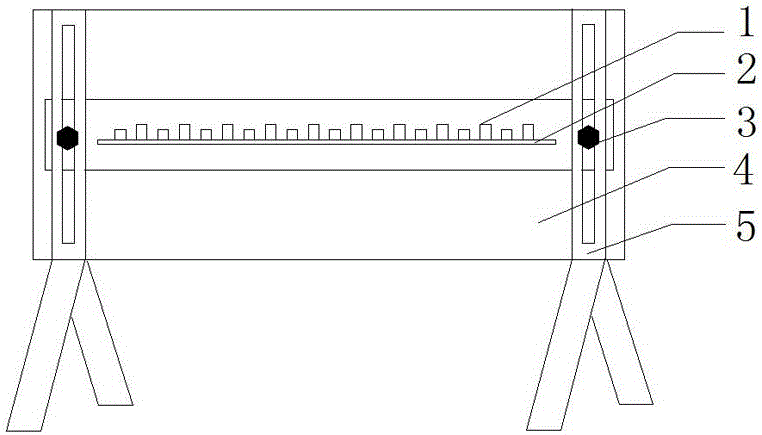

[0012] In order to obtain a slender and clear light beam, a slit is made on the hard steel sheet to cover the excess light beam, the width of the slit is 0.8mm; at the same time, in order to provide a reference for the length measurement, a scale is marked on the top of the slit with silver paint, the smallest scale 5mm, measuring range 20cm; the scale is fixed on the support frame by bolts. The shooting scale made is composed of a scale line 1, a gap 2, a fixing bolt 3, a black bottom plate 4, and a support frame 5.

[0013] Fix the defective detonating tube on the back of the shooting ruler, and align the defective part with the gap of the ruler. In order to make the nonel at the test site achieve a stable detonation, a length of 70 cm was left at the detonating end of the nonel.

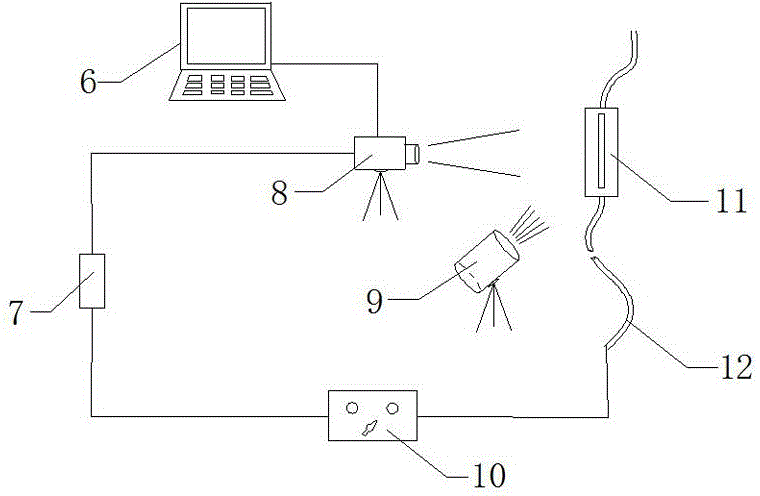

[0014] Dandong Danmei DCI-1000W high-efficiency metal halide lamp is used as the shooting light source. The high-speed camera adopts a short lens, F1.4 aperture, and is shooting directly at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com