Efficient oxygen increasing tank

An oxygen tank and high-efficiency technology, applied in the field of sewage treatment, can solve the problems of affecting the survival rate of aquarium fish, consuming the physical energy of aquarium fish, and gas source escaping the water surface, etc., achieving good oxygenation effect, preventing oxygen backflow, improving The effect of the degree of turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

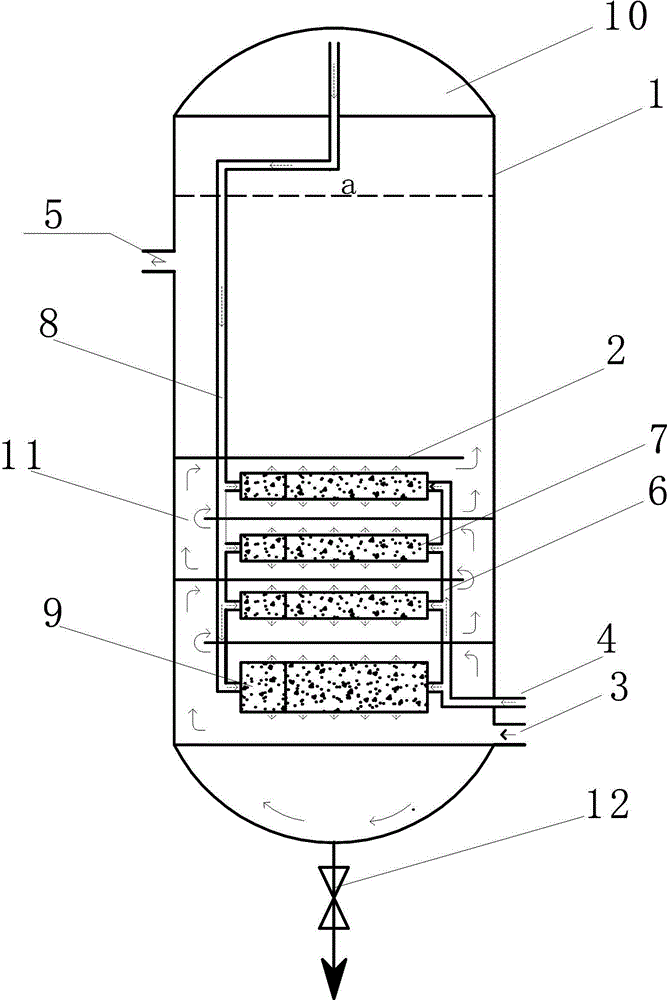

Method used

Image

Examples

Embodiment 1

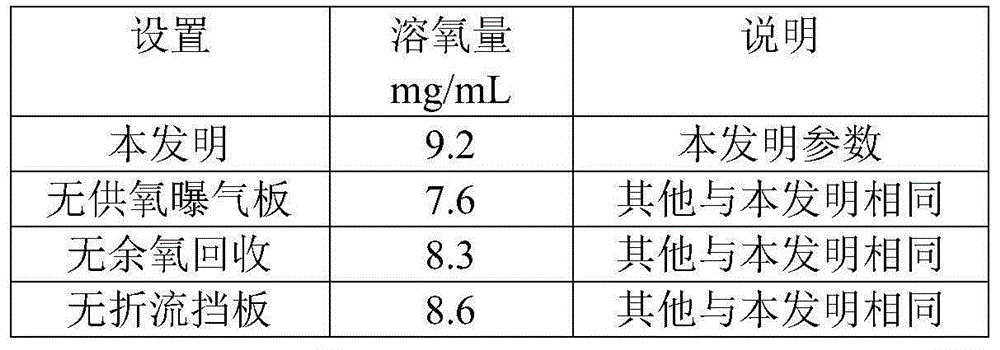

[0036] Embodiment 1: the impact of different oxygenation methods on dissolved oxygen:

[0037] Parameter control: water flow is 600m 3 / h, the oxygen flow rate is 0.5m 3 / h, the cooling medium (cooling water) flow rate is 500m 3 / h, the temperature is 5°C, and the residual oxygen recovery chamber 10 (ie the pressure reflected by the top pressure gauge) is 0.12Mpa.

[0038] After testing, the dissolved oxygen content was 9.2mg / mL.

[0039] After testing, the influence of different oxygenation methods on dissolved oxygen is shown in Table 1. From Table 1, it can be seen that under the same conditions, the method according to the present invention has no oxygen supply aeration plate, no residual oxygen recovery device, and no baffle plate. , the amount of dissolved oxygen is large.

[0040] Table 1 Effect of different oxygenation methods on dissolved oxygen

[0041]

Embodiment 2

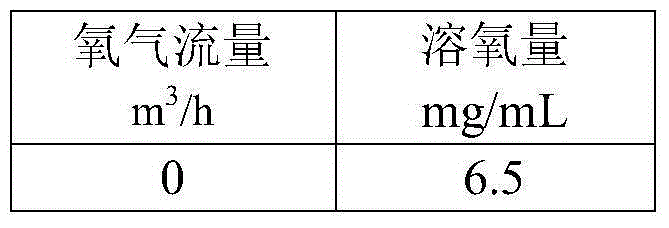

[0042] Embodiment 2: the influence of oxygen intake on dissolved oxygen:

[0043] The structural parameters are the same as those in Example 1, except that the flow rate of oxygen intake is different. After testing, the influence of oxygen intake on dissolved oxygen is shown in Table 2. It can be seen from Table 2 that under the same conditions, the greater the oxygen intake, the greater the dissolved oxygen.

[0044] Table 2 The effect of oxygen intake on dissolved oxygen

[0045]

[0046]

Embodiment 3

[0047] Embodiment 3: the influence of temperature on dissolved oxygen:

[0048] The structural parameters are the same as in Example 1, only the temperature (regulated by the flow rate of the cooling medium) is different. After testing, the influence of temperature on dissolved oxygen is shown in Table 3, as can be seen from Table 3: under the same conditions, the lower the temperature, the higher the dissolved oxygen amount. big.

[0049] Table 3 Effect of temperature on dissolved oxygen

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com