Thin-layer wrapper spreading device

A dough and thin layer technology, applied in the direction of baking pancakes, oil/fat baking, etc., can solve the problem of low degree of automation, and achieve the effect of improving work efficiency, preventing missed connections or discontinuities, and improving the quality of paving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

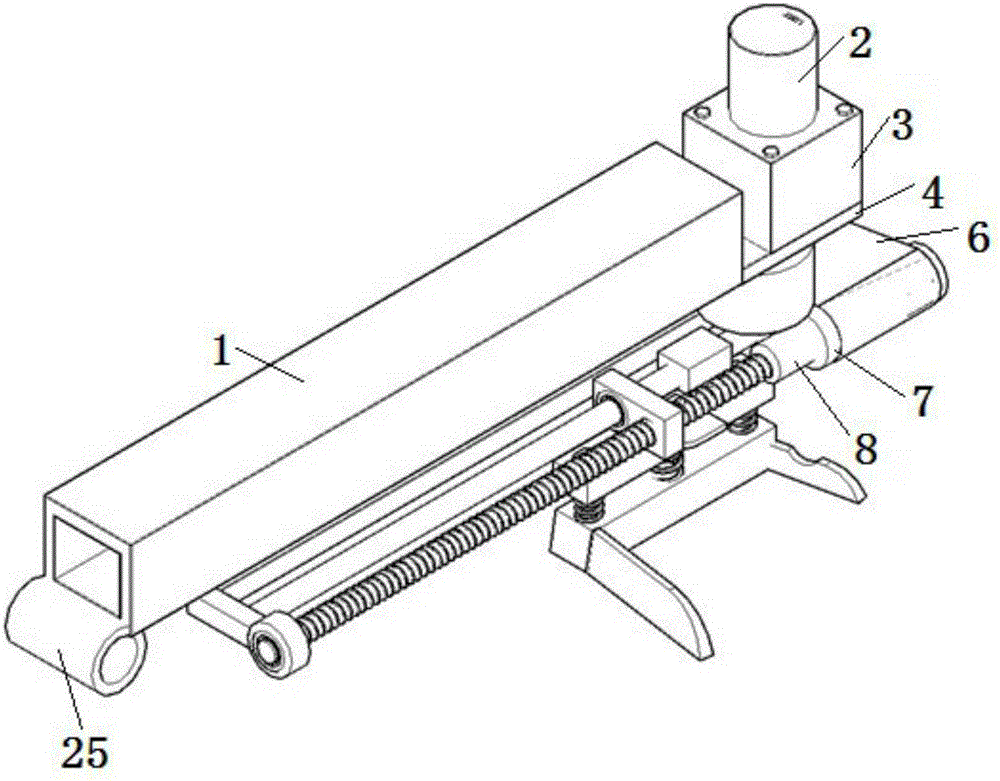

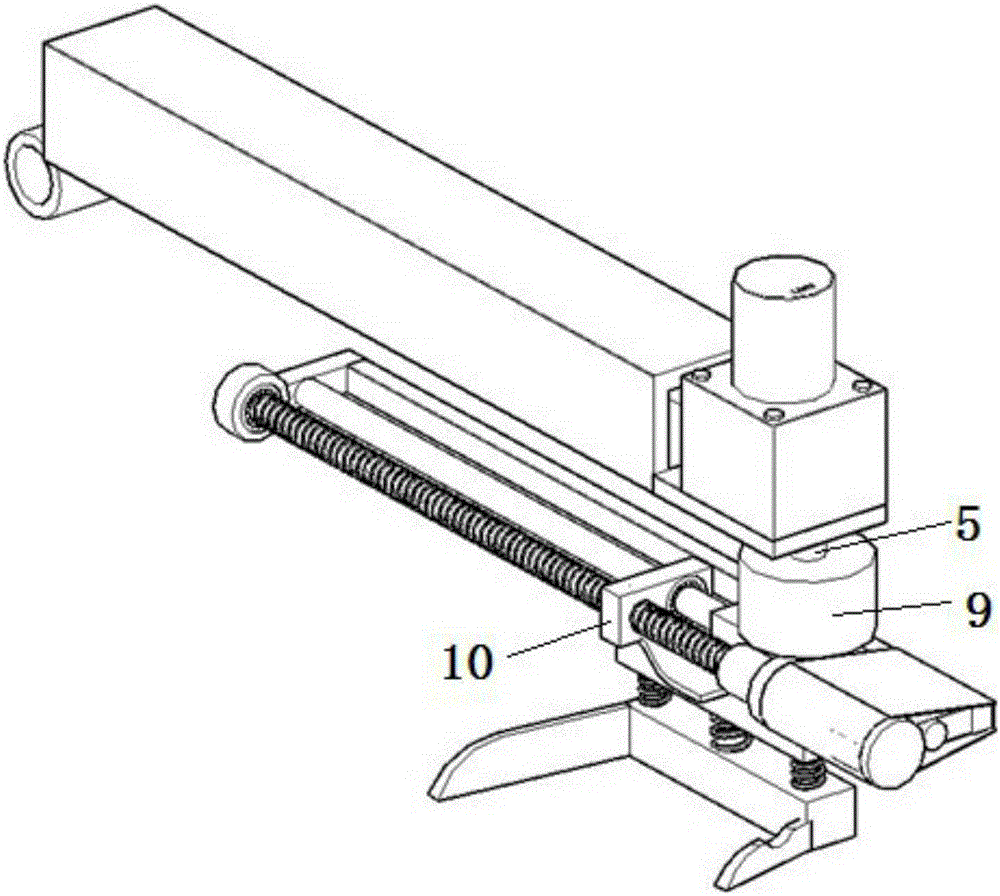

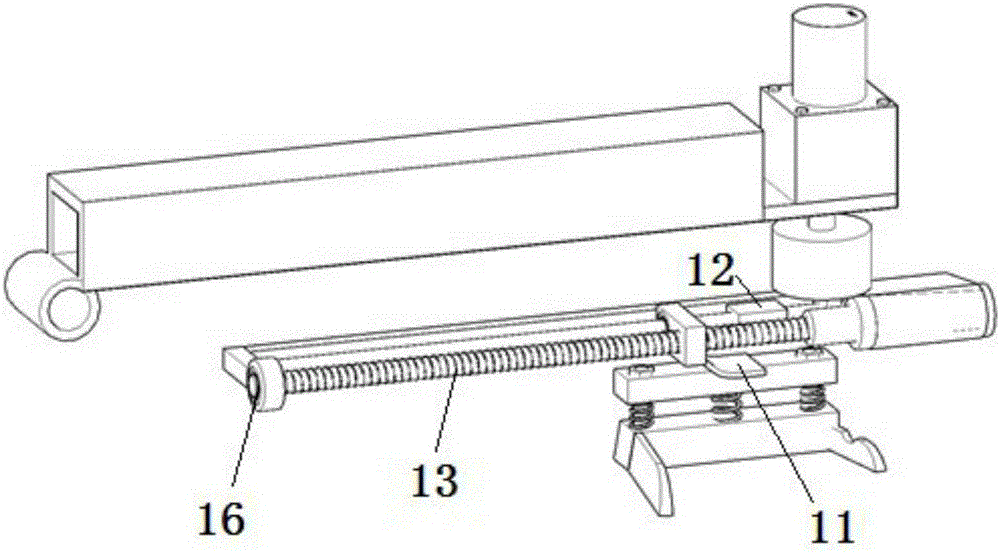

[0027] The device will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0028] Such as Figure 1-5 Shown, a kind of thin layer skin paving device, during use, there is the gap of 1-10mm between the scraper of this device and pot surface, batter is placed on and pot surface, big baffle plate (18), baffle plate main body ( 19), the trapezoidal scraper formed by the small baffle (20) wraps the batter; start the power switch, the vertical motor (2) and the horizontal motor (7) start, and the output shaft of the vertical motor (2) passes through the reducer (3) ), the drive shaft (5) drives the lead screw holder (15) to rotate, and at this time, the scraper spreads the batter evenly by rotation.

[0029] The horizontal motor (7) drives the lead screw (13) to rotate in the forward direction, the slide block (10) slides forward along the slide bar (14), and the batter in the scraper is completely spread along the circumference for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com