A kind of non-carrier adjuvant for vaccine, its preparation method and application

A carrier and adjuvant technology, applied in the field of biomedicine, can solve the problems of strong toxicity, poor ability to stimulate immune response, affecting normal cell metabolism, etc., and achieve the effect of low cytotoxicity and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

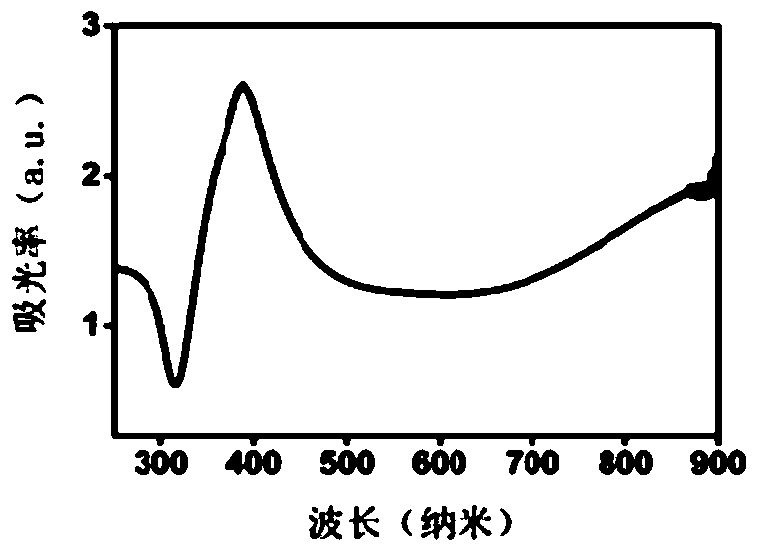

[0048] Example 1: Synthesis and characterization of silver nanorods

[0049] Preparation of silver nanorods:

[0050] At room temperature, 0.5ml 3M AgNO 3 Add 2.5ml 2M PVP to 25mL polyethylene glycol with continuous stirring, and continue stirring for 5 minutes before heating. The mixture was heated to 80°C for 1 h, and continued to be heated to 90°C for 20 h. After cooling, use a large amount of ethanol or water to precipitate, slowly pour the upper liquid, add water to dissolve the precipitate, and ultrasonically in a water bath at 20°C to obtain silver nanorods.

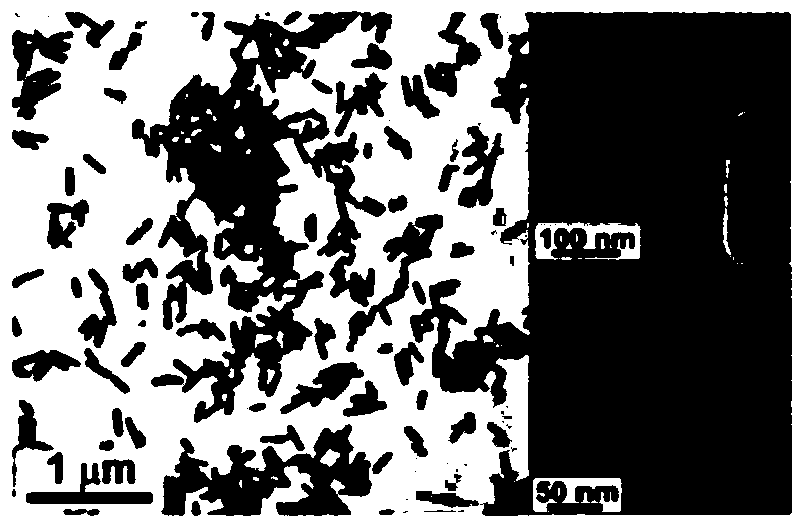

[0051] The prepared silver nanorods were characterized by FIRT, TEM and DLS, and the results are shown in Figure 2 (A), (B), (C), (D) and (E).

[0052] It can be seen from the FIRT image of Figure 2(A) that the silver nanorods have two different peaks at 400nm and 900nm, indicating that they belong to a rod-like structure; from the TEM image of Figure 2(B), it can be seen that the diameter of the silver nanorods is about...

Embodiment 2

[0058] Preparation of silver nanorods:

[0059] At room temperature, 0.5ml 1M AgNO 3 Add 2.5ml 0.5M PVP to 25ml polyethylene glycol with continuous stirring, and continue stirring for 5 minutes before heating. The mixture was heated to 80°C for 1 h, and continued to be heated to 90°C for 20 h. After cooling, use a large amount of ethanol or water to precipitate, slowly pour the upper liquid, add water to dissolve the precipitate, and ultrasonically in a water bath at 20°C to obtain silver nanorods.

[0060] The prepared silver nanorods have a diameter of about 10 nm and a length of about 150 nm.

Embodiment 3

[0062] Preparation of silver nanorods:

[0063] At room temperature, 0.5ml 5M AgNO 3 Add 2.5ml 6M PVP to 25ml polyethylene glycol with continuous stirring, and continue stirring for 5 minutes before heating. The mixture was heated to 80°C for 1 h, and continued to be heated to 90°C for 20 h. After cooling, use a large amount of ethanol or water to precipitate, slowly pour the upper liquid, add water to dissolve the precipitate, and ultrasonically in a water bath at 20°C to obtain silver nanorods.

[0064] The prepared silver nanorods have a diameter of about 120nm and a length of about 300nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com