Tool-crashing prevention system of numerically controlled lathe and judgment method for tool-crashing prevention system

A CNC lathe and control system technology, applied in the direction of turning equipment, toolholder accessories, measuring/indicating equipment, etc., can solve problems such as tool collision accidents, and achieve the effects of eliminating influence, reliable detection, and strong accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with embodiment the present invention is further described.

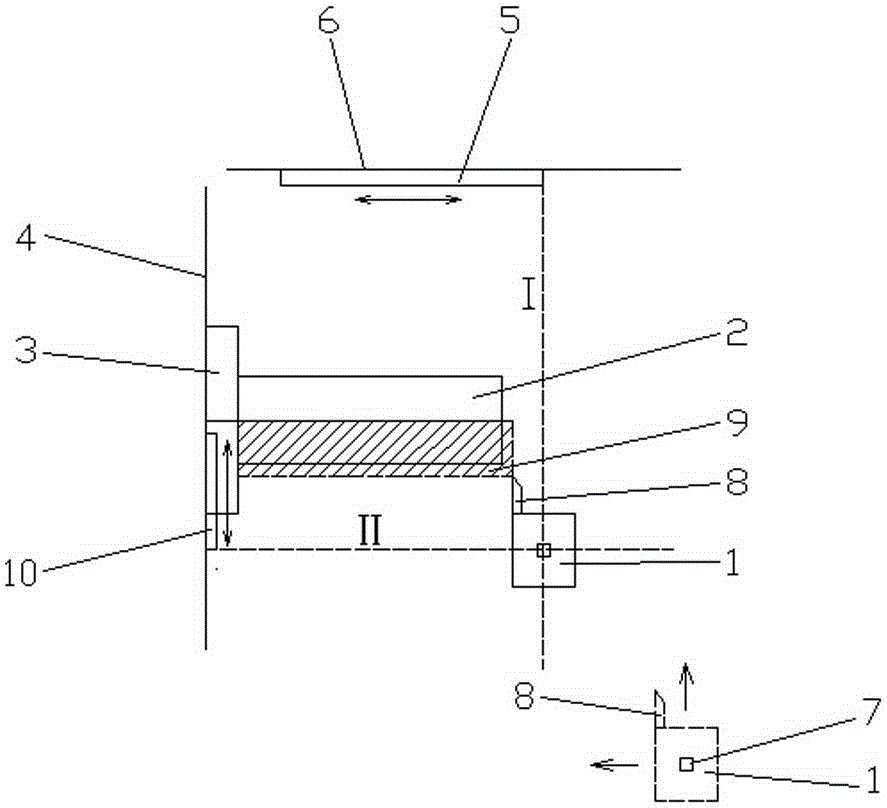

[0033] see figure 1 , a CNC lathe anti-collision tool system, comprising a tool rest 1 and a chuck 3 for fixing a workpiece 2, a mirror reflective photoelectric switch 7 is arranged in the middle of the tool rest 1, and the tool rest 1 is equipped with a rough turning tool 8, Install the X-axis reflector 10 on the spindle box of the lathe, and install the Y-axis reflector 5 on the rear baffle of the lathe. When the turning tool moves, will the mirror reflection photoelectric switch 7 on the tool holder 1 receive the X-axis and Y-axis of the lathe? The signal of the reflector on the axis can judge the position of the turning tool.

[0034] The judgment method of the anti-collision tool system of the numerical control lathe, its steps are:

[0035] 1. For the determination of the position of the CNC system turning tool on the Y axis, when the tool holder 1 moves to the dotted line I in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com