Constructed Wetland with Three Dikes and Two Channels Enhanced Surface Flow and Its Operation Method

A technology of artificial wetlands and embankments, applied in chemical instruments and methods, aerobic process treatment, water/sludge/sewage treatment, etc., can solve the problems of low water purification efficiency, large floor space, difficult maintenance, etc., to overcome Effects of large footprint, increased contact area, and increased processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

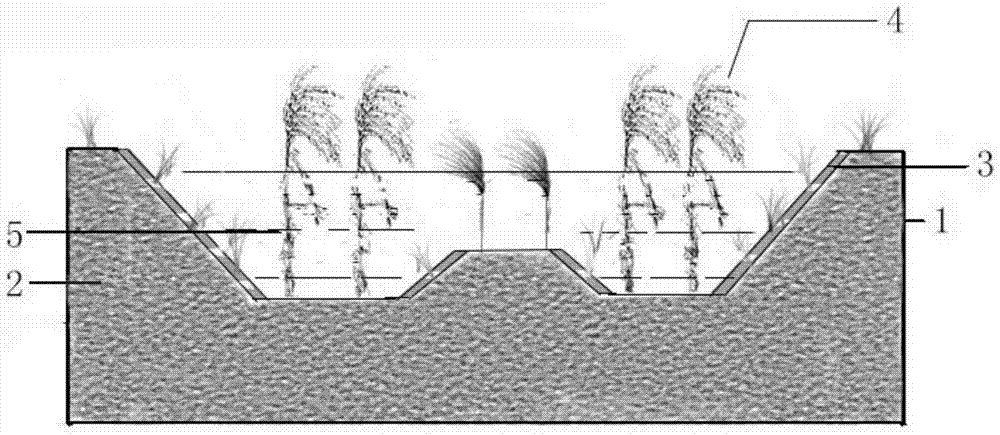

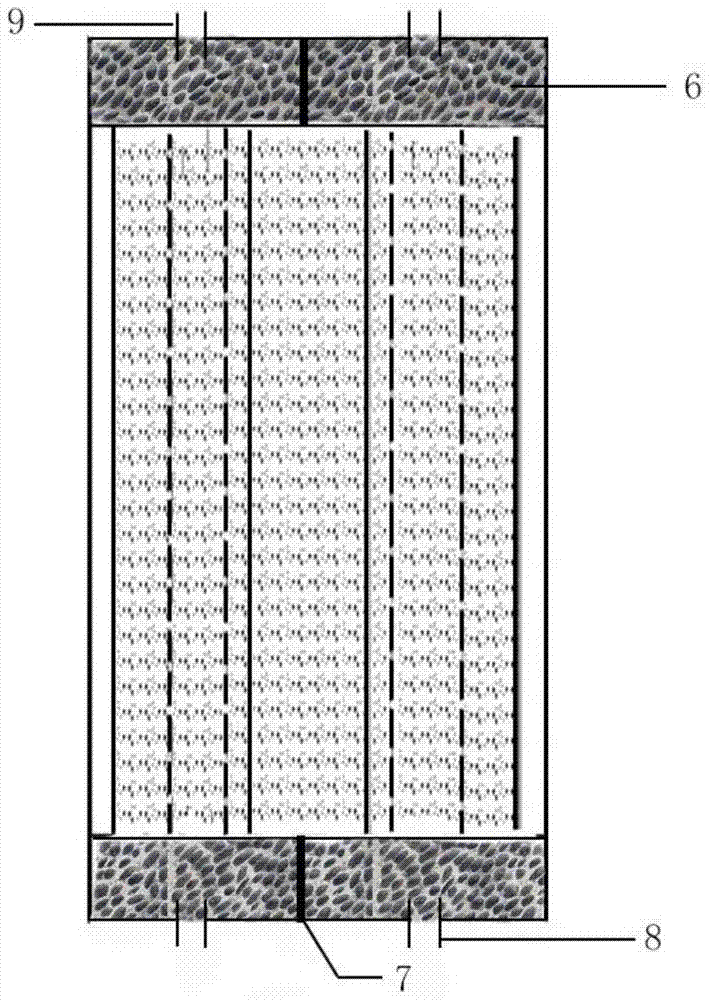

[0029] The artificial wetland with three embankments and two roads in this embodiment, such as figure 1 with figure 2 As shown, it includes bed body 1 (made of concrete body) and matrix 2. The bed body 1 is filled with a matrix 2, and the matrix 2 is soil. The water inlet end of the bed body 1 is provided with a water distribution weir 6 and a water inlet pipe 9, the water outlet end is provided with a drain pipe 8, and both ends are provided with baffle plates 7 to separate the two water inlet pipes or drain pipes. Control valves can be set on the water inlet pipe 9 and the drain pipe 8 to adjust the water inlet and outlet. The water distribution weir 6 is a triangular weir with a height of 0.4-0.45m piled up by gravel or stones with a particle size of 12-20cm. The cross section of the bed body 1 is rectangular, and the ratio of the width to the height of the bed body 1 is 1.8:1-2.0:1. The bed body 1 is inclined from the water inlet end to the water outlet end in the len...

Embodiment 2

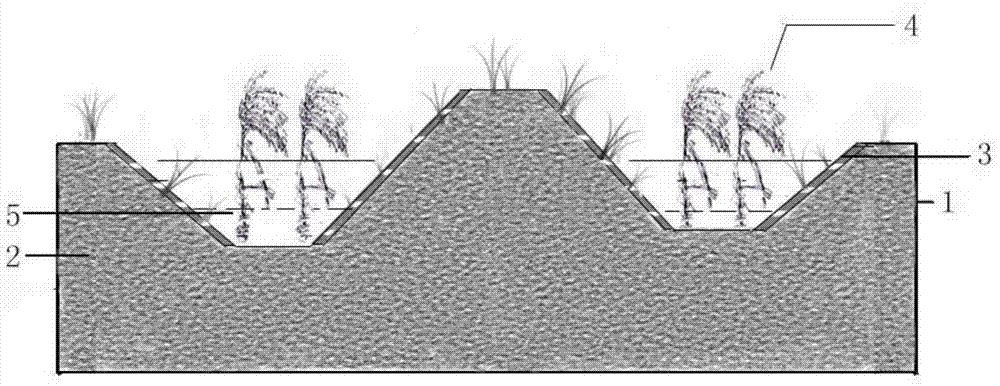

[0033] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the height of the middle embankment is 20cm-30cm higher than the left embankment and the right embankment, and the non-submerged operation mode is adopted:

[0034] By controlling the speed of water in and out, and adjusting the water level of the two grooves, the middle embankment will not be submerged; the water flows through multiple filtrations of substrates, animals, plants and microorganisms to achieve sufficient purification and is discharged through the drain pipe.

[0035] In this embodiment, because the middle embankment is higher than the left embankment and the right embankment, the system realizes the symbiosis of wet plants and aquatic plants, which increases the degree of natural restoration of the system, thereby increasing the biodiversity in the system. The slope design greatly increases the contact area between the substrate and the sewage, improving the efficie...

Embodiment 3

[0037] Such as Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the height of the middle embankment is the same as that of the left embankment and the right embankment, and the alternate dry and wet operation mode is adopted:

[0038] Make the two trenches run alternately between dry and water, provide sufficient oxygen to enable plants and microorganisms to perform aerobic respiration, switch between aerobic respiration and anaerobic respiration, and maintain the activity of plants and microorganisms to the greatest extent; by controlling the in and out Water speed, adjusts the water level in the gutter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com