A kind of acicular wollastonite/urea-formaldehyde resin formula for glass wool insulation material

A needle-shaped wollastonite and urea-formaldehyde resin technology, which is applied in the field of modified urea-formaldehyde resin formulations, can solve the problems of no substantial impact on the performance of urea-formaldehyde resin, and no report on permeability, so as to improve interfacial compatibility and excellent The effect of carrying effect and speeding up the dipping speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

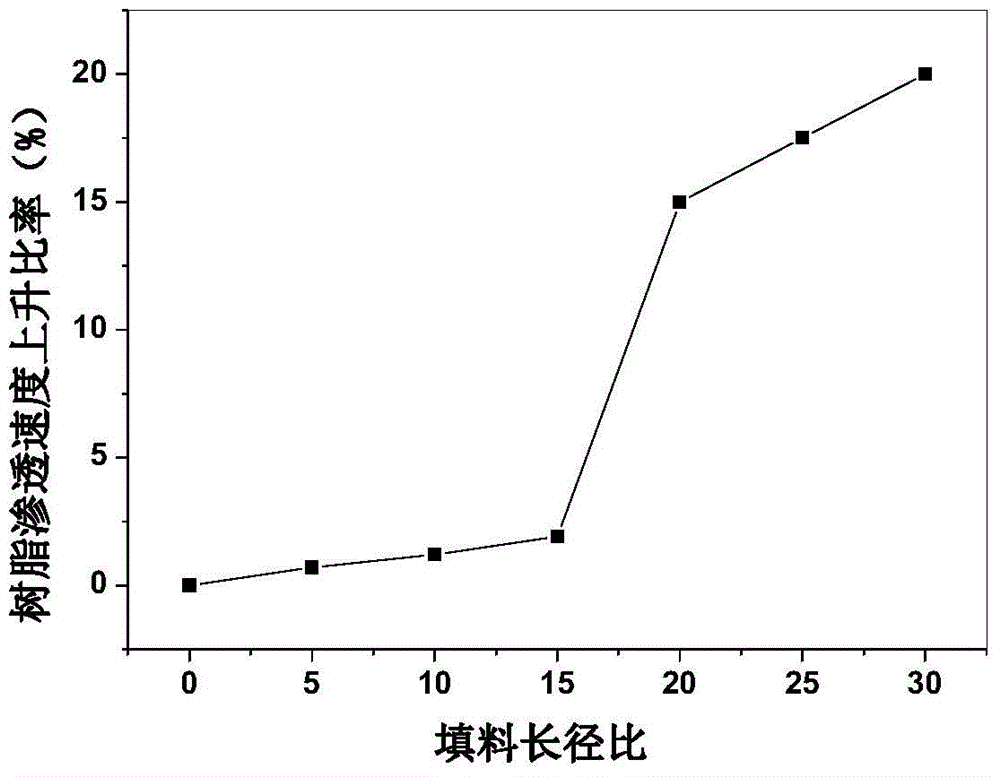

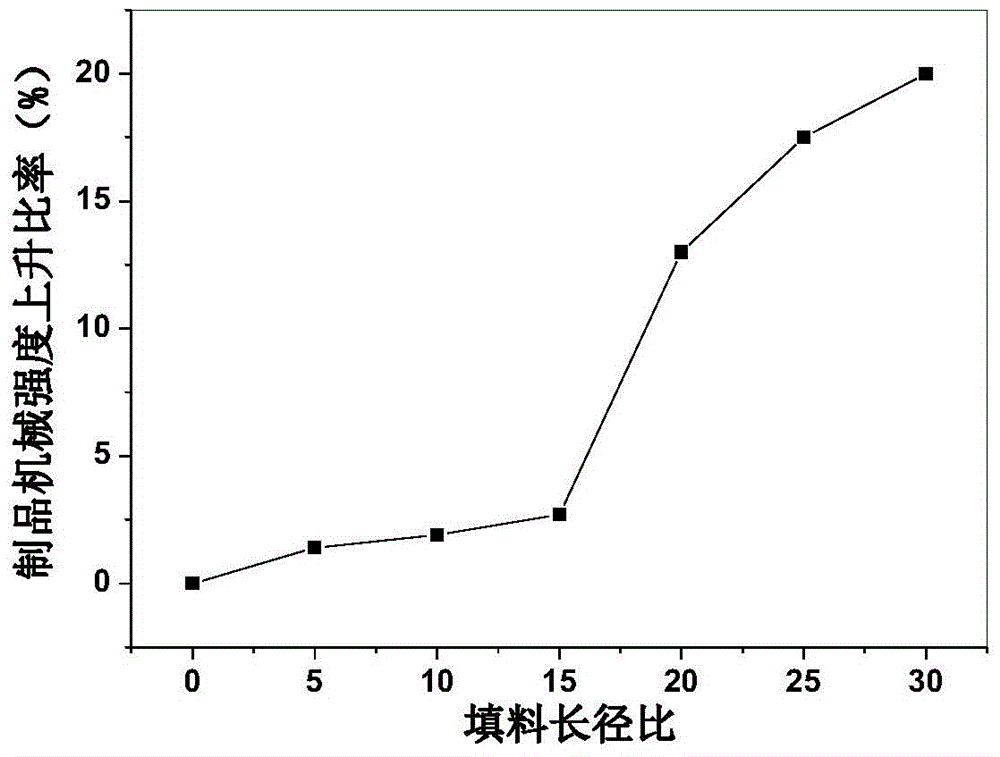

[0026] A high-permeability acicular wollastonite / urea-formaldehyde resin formula for glass wool insulation materials, which consists of 65kg formaldehyde solution, 18kg urea, 10kg melamine, and 7kg acicular silica fume with an aspect ratio of 25:1 Stone, mix and stir evenly, and then adjust the pH value to 7-8 with sodium hydroxide to obtain acicular wollastonite / urea-formaldehyde resin with high permeability. Compared with pure urea-formaldehyde resin, the formula can increase the penetration speed of glass fiber by 30-35%, and the mechanical strength of the prepared glass fiber reinforced plastic product can be increased by 20-35%.

Embodiment 2

[0028] A high-permeability acicular wollastonite / urea-formaldehyde resin formula for glass wool insulation materials, which consists of 70kg formaldehyde solution, 15kg urea, 14kg melamine, and 1kg acicular silica fume with an aspect ratio of 25:1 Stone, mix and stir evenly, and then adjust the pH value to 7-8 with sodium hydroxide to obtain acicular wollastonite / urea-formaldehyde resin with high permeability. Compared with pure urea-formaldehyde resin, the formula can increase the penetration rate of glass fiber by 15-20%, and the mechanical strength of the prepared glass fiber reinforced plastic product can be increased by 10-20%.

Embodiment 3

[0030] A high-permeability acicular wollastonite / urea-formaldehyde resin formula for glass wool insulation materials, which consists of 55kg formaldehyde solution, 25kg urea, 10kg melamine, and 10kg acicular silica fume with an aspect ratio of 20:1 Stone, mix and stir evenly, and then adjust the pH value to 7-8 with sodium hydroxide to obtain acicular wollastonite / urea-formaldehyde resin with high permeability. Compared with pure urea-formaldehyde resin, the formula can increase the penetration rate of glass fiber by 25-35%, and the mechanical strength of the prepared glass fiber reinforced plastic product can be increased by 20-30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com