Starch-based foaming packing material precursor, starch-based foaming packing material and preparation methods

A packaging material and starch-based technology, applied in the field of starch-based foam packaging materials, can solve the problems of bulky, high cost, and space-consuming foam packaging materials, and achieve convenient use of microwave ovens, cost savings, and reduced storage and transportation space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The starch-based foam packaging material of the present embodiment comprises the following steps:

[0042] (1) Weighing materials: hydroxypropyl starch 83wt%, polyvinyl alcohol 7wt%, glycerin 5wt%, talcum powder 2wt%, water 3wt%;

[0043] (2) Put 83wt% of hydroxypropyl starch, 7wt% of polyvinyl alcohol and 2wt% of talcum powder into a high-speed mixer, and pre-mix for 5min at a rate of 70r / min at room temperature;

[0044] (3) Add glycerin 5wt% and water 3wt% and blend at 60°C at a rate of 120r / min for 25min to ensure uniform mixing;

[0045] (4) Open twin-screw extruder, add plasticizer in the pretreatment material that step (3) obtains, carry out extrusion granulation:

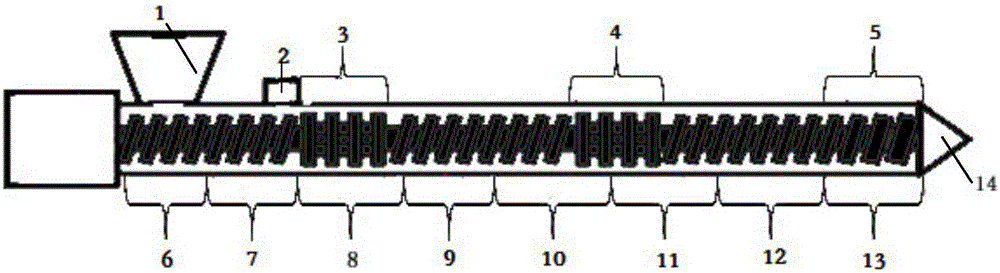

[0046] (41) The twin-screw extruder used in this implementation is as figure 1 As shown, the screw is provided with a kneading section 3 , a kneading section 4 , a compression section 5 and a feeding section 6 . Turn on the twin-screw extruder and set the seven-stage temperature of the twin-screw e...

Embodiment 2

[0054] The starch-based foam packaging material of the present embodiment comprises the following steps:

[0055] (1) weighing materials: hydroxypropyl starch 86wt%, polyvinyl alcohol 4wt%, sorbitol 8wt%, calcium carbonate 1wt%, water 1wt%;

[0056] (2) Put 83wt% of hydroxypropyl starch, 7wt% of polyvinyl alcohol and 2wt% of talcum powder into a high-speed mixer, and pre-mix for 8min at a rate of 200r / min at room temperature;

[0057] (3) Add glycerin 8wt% and water 1wt% and blend at 50°C for 20min at a rate of 200r / min to ensure uniform mixing;

[0058] (4) Open twin-screw extruder, add plasticizer in the pretreatment material that step (3) obtains, carry out extrusion granulation:

[0059] (41) Turn on the twin-screw extruder and set the temperature of the seven sections of the twin-screw extruder to be the temperature respectively: the temperature of the first section 7 of the screw is 65°C, the temperature of the second section of the screw is 85°C, and the temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com