Plant covering material and preparation method thereof

A plant covering and base cloth layer technology, which is applied in the field of plant covering materials and its preparation, can solve the problems that the covering film does not isolate ultraviolet rays and withstand high and low temperatures, has a narrow application range, and has no preparation method, and achieves a wide application range and high production efficiency. High, good work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The preparation method of the plant covering material comprises the following steps: a, purchasing the raw materials required above; b, adding polyvinyl chloride, dioctyl ester, soybean oil, ultraviolet absorber, anti-cold agent, titanium dioxide, calcium carbonate and water In an ordinary mixer, the stirring speed is 200r / min, and the stirring time is 8min. Stir evenly to prepare a coating liquid; c, pour the coating liquid into the liquid discharge tank 5 of the scraping equipment, and scrape it on the On the two surfaces of the base cloth layer, the coating thickness is 0.15 mm, which is the protective layer; d, the base cloth layer after scraping is ventilated and dried to prepare the plant covering material.

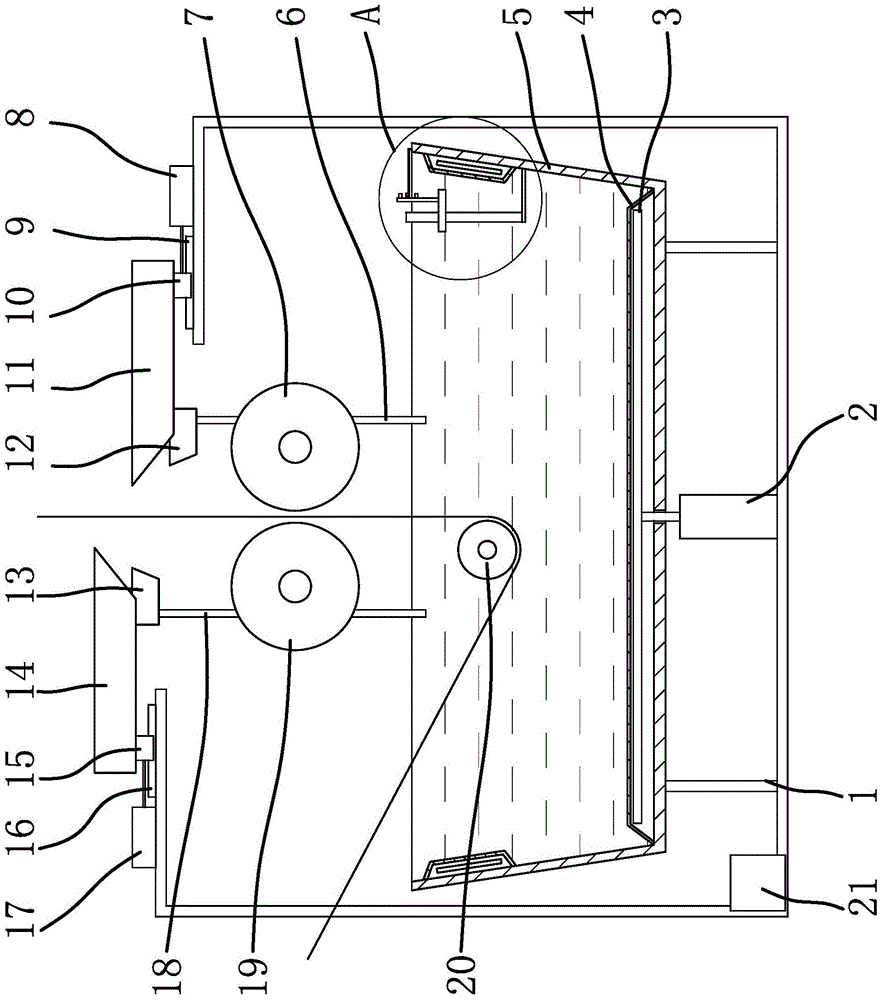

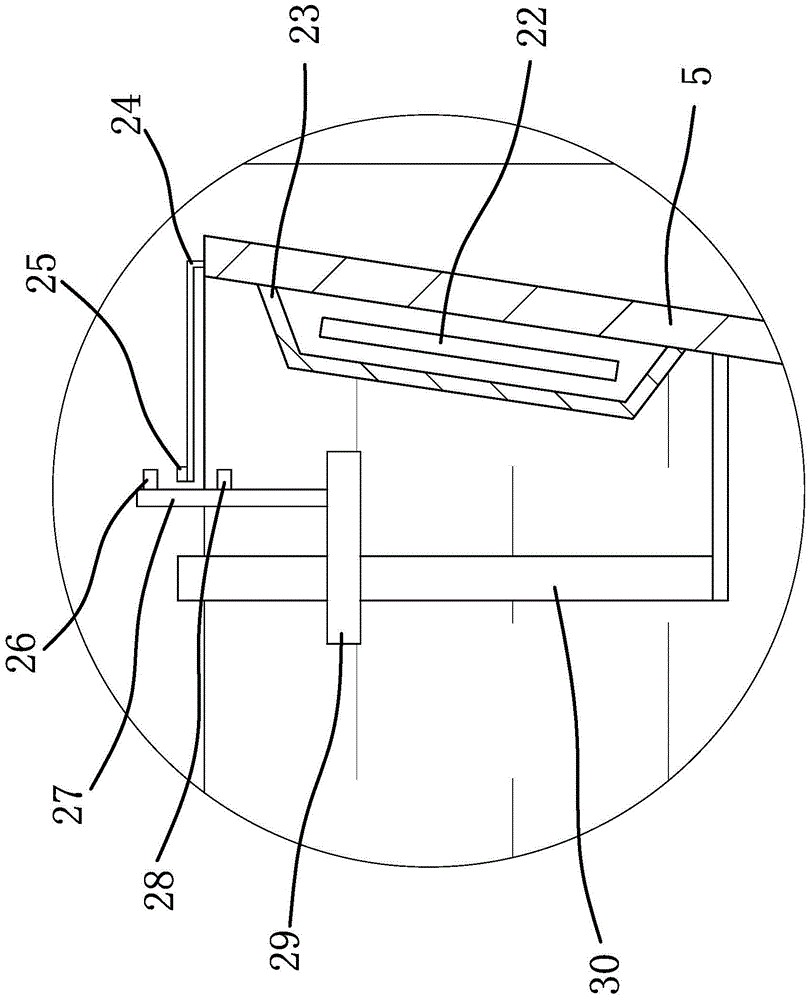

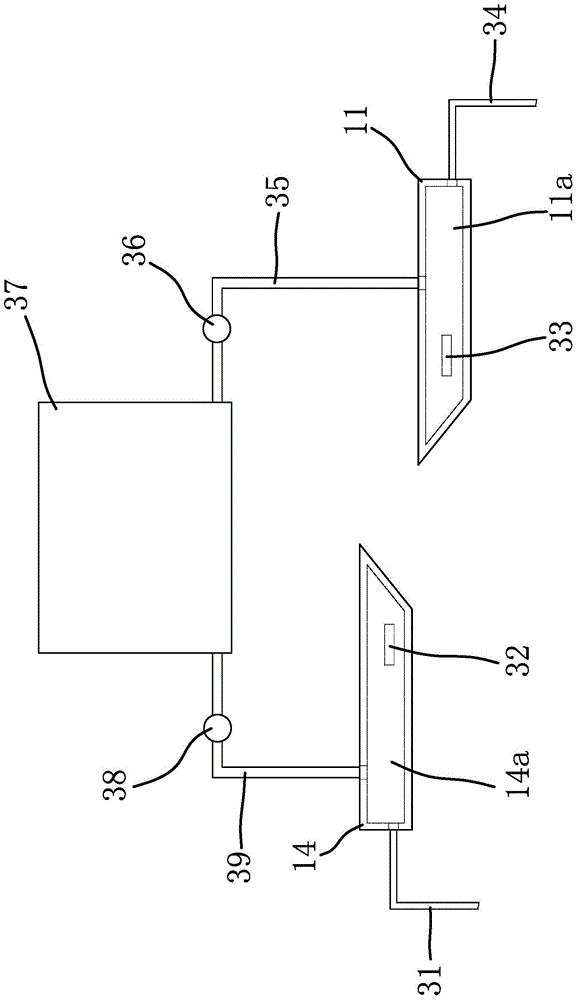

[0042] Such as figure 1 , figure 2 As shown, the scraping equipment in step c includes a frame 1, a liquid discharge tank 5 is fixed on the frame 1, and a liquid discharge tank 5 is fixed on the frame 1 by bolt connection; There is a guide roller 20, and t...

Embodiment 2

[0049] The preparation method of the plant covering material comprises the following steps: a, purchasing the raw materials required above; b, adding polyvinyl chloride, dioctyl ester, soybean oil, ultraviolet absorber, anti-cold agent, titanium dioxide, calcium carbonate and water In an ordinary mixer, the stirring speed is 250r / min, and the stirring time is 12min. Stir evenly to prepare a coating liquid; c, pour the coating liquid into the liquid discharge tank 5 of the scraping equipment, and scrape it on the On the two surfaces of the base cloth layer, the coating thickness is 0.25mm, which is the protective layer; d, the base cloth layer after scraping is ventilated and dried to prepare the plant covering material.

[0050] Such as figure 1 , figure 2 As shown, the scraping equipment in step c includes a frame 1, a liquid discharge tank 5 is fixed on the frame 1, and a liquid discharge tank 5 is fixed on the frame 1 by bolt connection; There is a guide roller 20, and t...

Embodiment 3

[0057] The preparation method of the plant covering material comprises the following steps: a, purchasing the raw materials required above; b, adding polyvinyl chloride, dioctyl ester, soybean oil, ultraviolet absorber, anti-cold agent, titanium dioxide, calcium carbonate and water In an ordinary mixer, the stirring speed is 300r / min, and the stirring time is 15min. Stir evenly to prepare a coating liquid; c, pour the coating liquid into the discharge tank 5 of the scraping equipment, and scrape it on the On the two surfaces of the base cloth layer, the coating thickness is 0.35mm, which is the protective layer; d, the base cloth layer after scraping is ventilated and dried to prepare the plant covering material.

[0058] By adopting the preparation method, the protective layer is firmly fixed on the base cloth layer by scraping, without excessive manual operations, continuous and uninterrupted production can be realized, and the production efficiency is high.

[0059] Such as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com