Spinning device for preparation of micro-nanofibers

A technology of spinning device and spinning system, which is applied in the field of preparation devices for micro-nano fiber materials, can solve problems affecting continuous production, etc., and achieve the effects of improving fiber mechanical properties, improving production efficiency, and reducing the content of beads in micro-nano fiber nets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0033] 1. Description of device structure:

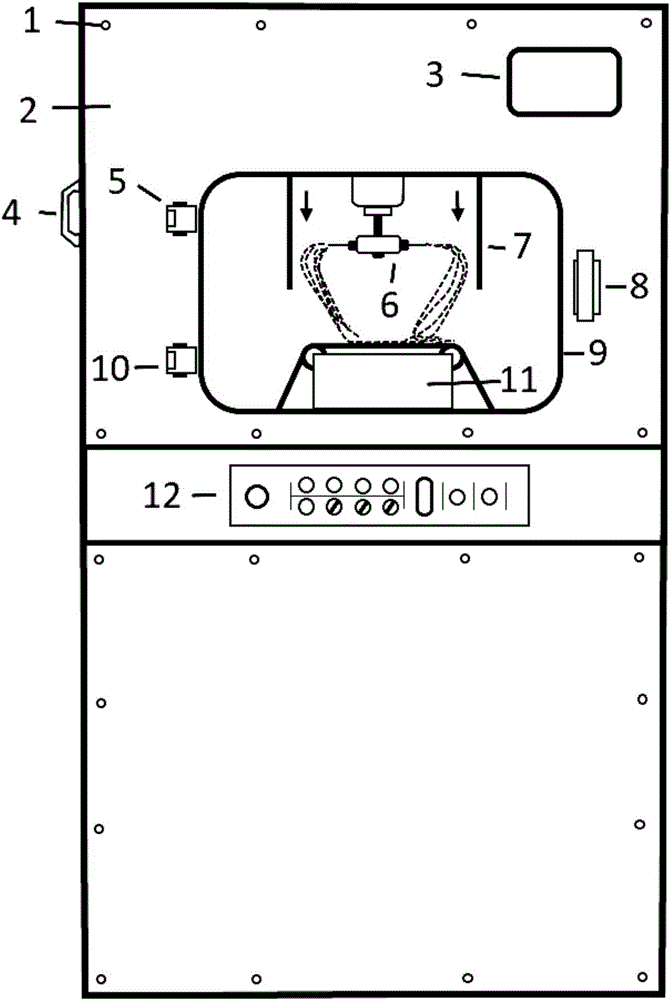

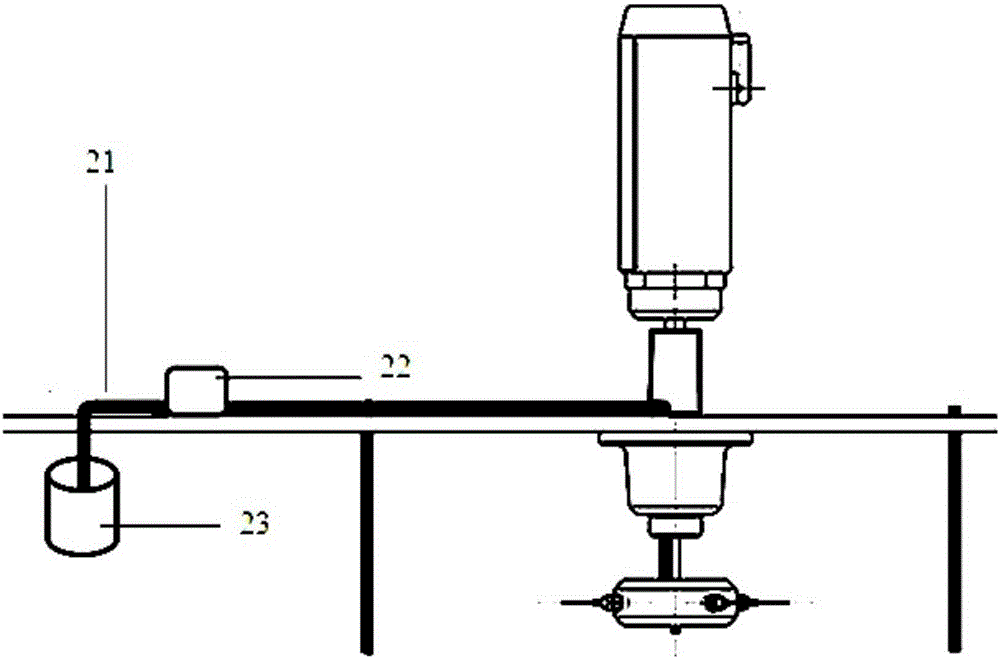

[0034] A spinning device for preparing micro-nano fibers, including a collection system, a spinning system, a continuous feeding system, a dehumidification system, and a control system.

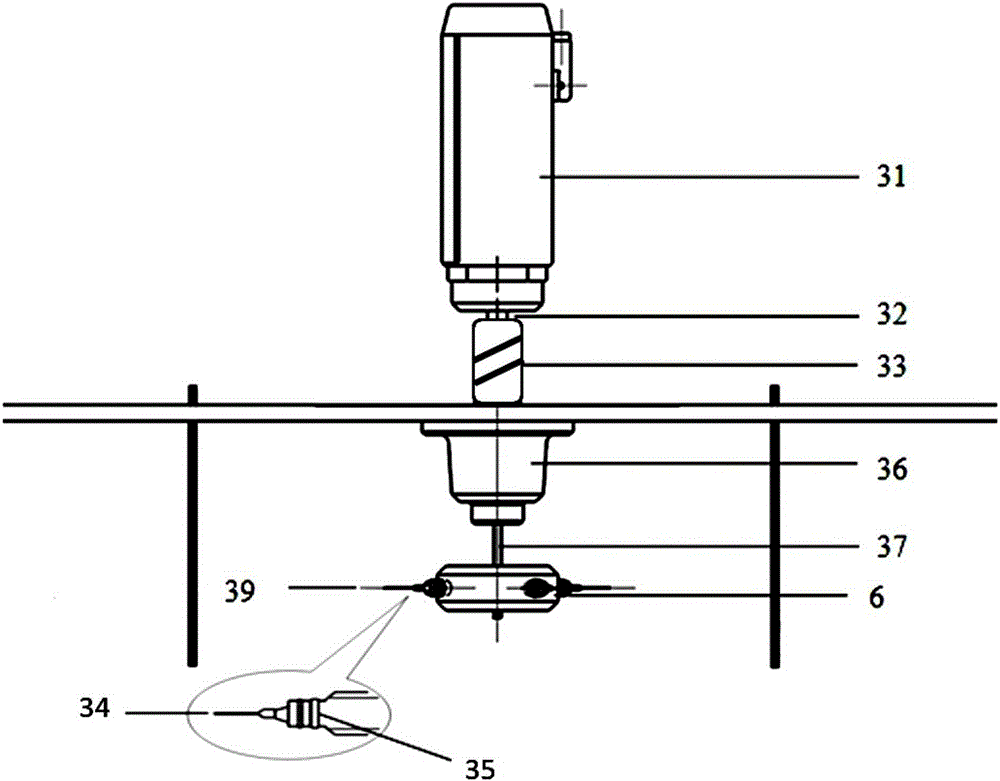

[0035] Spinning system comprises motor 31, insulating shaft coupling 33 and spinneret 6, and the rotating shaft 32 of motor 31 and the rotating shaft 37 of spinneret 6 are all installed vertically, and realize connection by insulating shaft coupling 33; The inside of the main body of the device 6 is hollow, and its top is provided with a spinning solution inlet; the outside of the main body of the spinneret 6 is surrounded by a plurality of dispensing needles 34, and each dispensing needle 34 passes through the connector 35 and the inside of the spinneret 6 respectively. The connection is realized; the main body of the spinneret 6 is arra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com