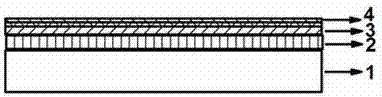

A kind of preparation method of ultra-high protective silver conductive film

A conductive film, ultra-high technology, applied to the conductive layer on the insulating carrier, cable/conductor manufacturing, circuit, etc., can solve the problems of the decline of the conductive performance of the silver wire network and the insufficient protective performance of the film, and achieve stable physical and chemical properties. Scattering of light, high light transmittance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0020] PET was used as the substrate. Tear off the protective film on the new substrate, put it into acetone and ethanol and sonicate it for 5 minutes respectively. Then dry it with an infrared oven lamp. Then put it into the plasma cleaner and vacuum clean it for 5 minutes;

[0021] Cut the DJB-823 solid film protective agent into powder, weigh 0.5-2 g, and add it into 100 ml of mixed solvent (No. 120 solvent gasoline 60%, n-butanol 40%). Heat to 55-65°C in a water bath with gentle stirring for 10 minutes. After the protective agent is completely dissolved into a clear solution, keep the temperature of the water bath at 50-65°C for use;

[0022] On the processed substrate, a layer of DJB-823 solid film protectant solution was coated with a Gardco Automatic Drawdown Machine DP8301 sheet coating machine. Then, it was first baked with an infrared baking lamp for 5 minutes, and then dried in a vacuum oven at 100° C. for 10 minutes under vacuum. Obtain a bonding layer with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com