Preparation method for ZnO microspherical photo anode based on multilevel structure and photo anode prepared with method

A photoanode and microsphere technology, applied in the field of photoanode, can solve the problems of complex process and easy damage of ZnO microsphere structure, and achieve the effect of simple preparation process, adjustable microsphere diameter and controllable film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

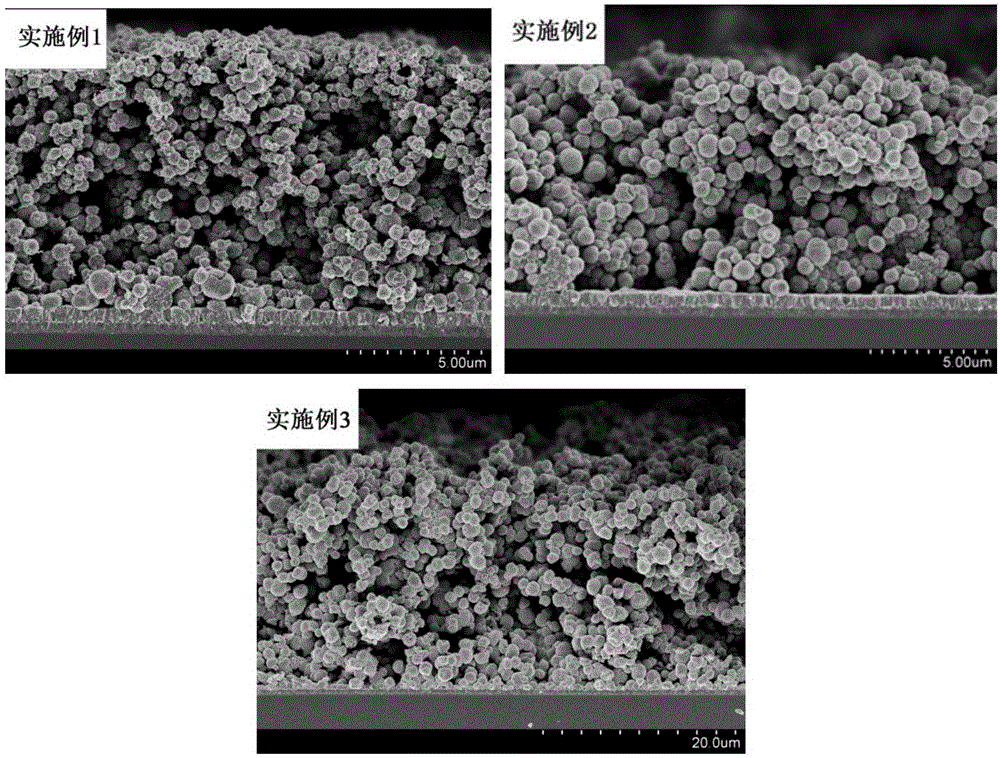

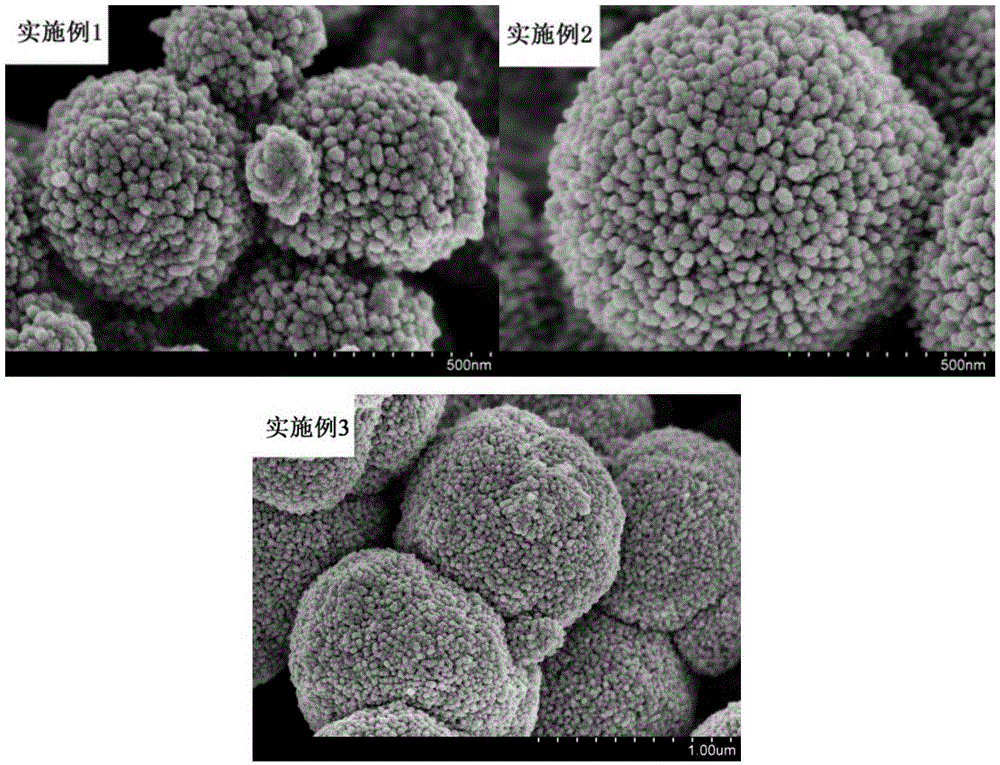

Embodiment 1

[0022] In this embodiment, a method for preparing a photoanode based on hierarchical structure ZnO microspheres, the steps are as follows:

[0023] (1) Measure 400ml of methanol solution and place it in a weighing bottle, weigh 7.90g of zinc acetate dihydrate (the concentration of zinc acetate dihydrate in methanol solution is 0.09M), and mix zinc acetate dihydrate with magnetic stirring. Add the above-mentioned weighing bottle to make it all dissolve in the methanol solution, stir the solution evenly to obtain the methanol solution of zinc acetate dihydrate;

[0024] (2) Put the cleaned FTO conductive substrate into the bottom of the above-mentioned weighing bottle filled with zinc acetate dihydrate methanol solution in the form of the conductive side facing up, put the weighing bottle on the lid and place it in a place that has been heated to In an oven at 60°C, and react at a constant temperature at this temperature for 24 hours; after the reaction, wash with deionized wate...

Embodiment 2

[0026] In this embodiment, a method for preparing a photoanode based on hierarchical structure ZnO microspheres, the steps are as follows:

[0027] (1) Measure 400ml of methanol solution and place it in a weighing bottle, weigh 11.41g of zinc acetate dihydrate (the concentration of zinc acetate dihydrate in methanol solution is 0.13M), and mix zinc acetate dihydrate with magnetic stirring Add the above-mentioned weighing bottle to make it all dissolve in the methanol solution, stir the solution evenly to obtain the methanol solution of zinc acetate dihydrate;

[0028] (2) Put the cleaned FTO conductive substrate into the bottom of the above-mentioned weighing bottle filled with zinc acetate dihydrate methanol solution in the form of the conductive side facing up, put the weighing bottle on the lid and place it in a place that has been heated to In an oven at 60°C, and react at a constant temperature at this temperature for 24 hours; after the reaction, wash with deionized wate...

Embodiment 3

[0030] In this embodiment, a method for preparing a photoanode based on hierarchical structure ZnO microspheres, the steps are as follows:

[0031] (1) Measure 400ml of methanol solution and place it in a weighing bottle, weigh 13.17g of zinc acetate dihydrate (the concentration of zinc acetate dihydrate in methanol solution is 0.15M), and mix zinc acetate dihydrate with magnetic stirring Add the above-mentioned weighing bottle to make it all dissolve in the methanol solution, stir the solution evenly to obtain the methanol solution of zinc acetate dihydrate;

[0032] (2) Put the cleaned FTO conductive substrate into the bottom of the above-mentioned weighing bottle filled with zinc acetate dihydrate methanol solution in the form of the conductive side facing up, put the weighing bottle on the lid and place it in a place that has been heated to In an oven at 60°C, and react at a constant temperature at this temperature for 48 hours; after the reaction, wash with deionized wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com