Method for sensing current in a conductor

A technology of conductors and conductive traces, which is applied in the direction of measuring electrical variables, periodic selective voltage/current level measurement, voltage/current isolation, etc., and can solve problems such as large volume, maximum circuit density limitation, and reduced lifespan.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

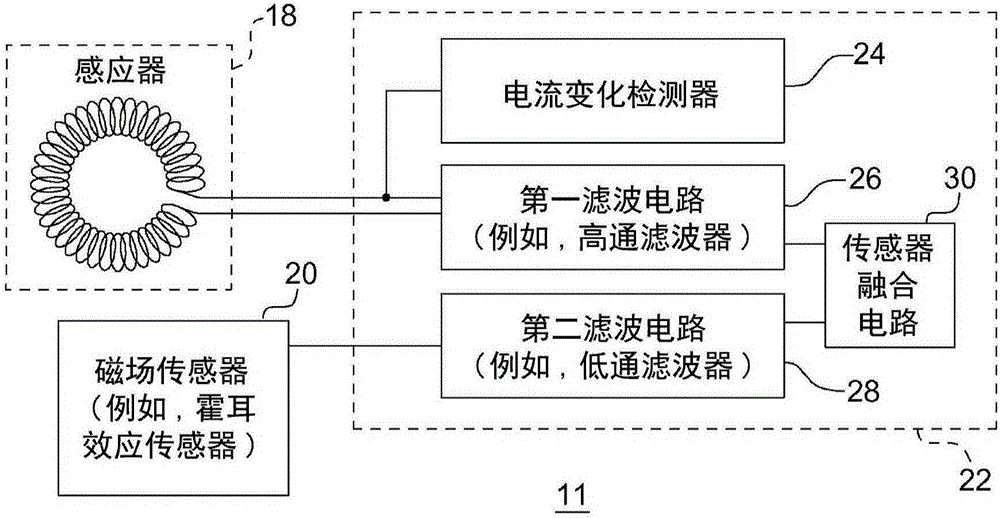

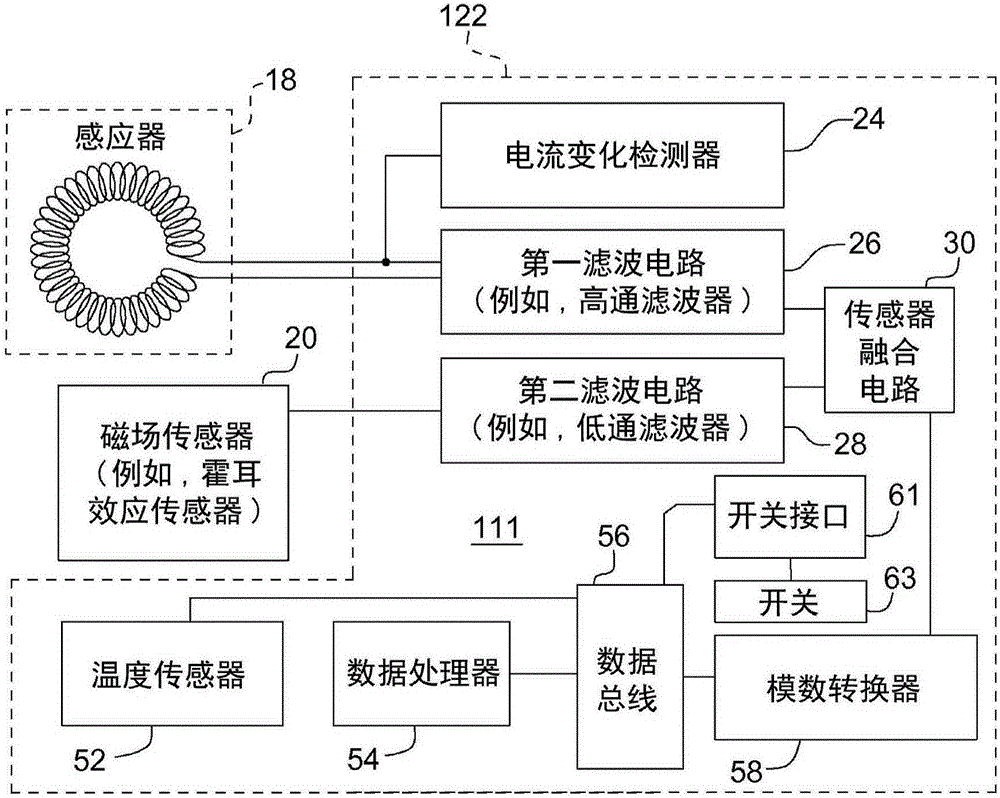

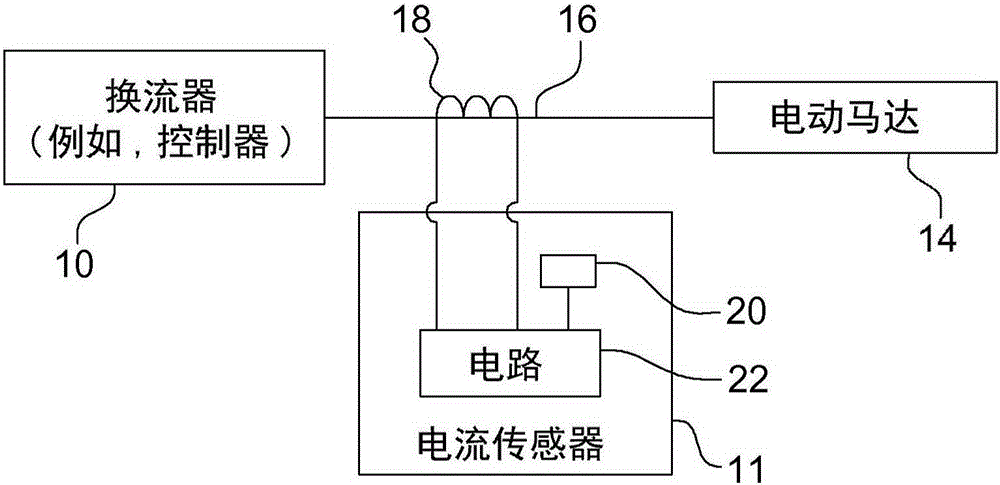

[0019] According to one embodiment, figure 1 A current sensor 11 is shown. As shown, the current sensor 11 includes a sensing conductor 16 (eg, image 3 The sensor 18 for the AC signal component (or the first AC signal component) of the observation signal in 16). Generally, conductors 16 may include conductors 16 located between a source and an electrical load. For example, conductors 16 may include conductors (eg, wires, cables, or busbars) 16 located between an output of inverter 10 or controller and an input of electric motor 14 .

[0020] Alternatively, the conductors 16 may be any power semiconductor device associated with a corresponding one or more output terminals of a corresponding power semiconductor device (eg, an insulated gate bipolar transistor (IGBT) or a metal oxide semiconductor field effect transistor (MOSFET)). conductor, conductive trace, wire, set of wires, bonding wire or set of bonding wires, wherein the current sensor 11 is configured to sense Inver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com