Clamp finger chain-type used plastic film collector

A recycling machine and residual film technology, applied in the direction of collectors, agricultural machinery and tools, applications, etc., can solve the problems of difficult manufacturing, high impurity content, residual film residue, etc., to achieve high operating speed, small impurity content, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

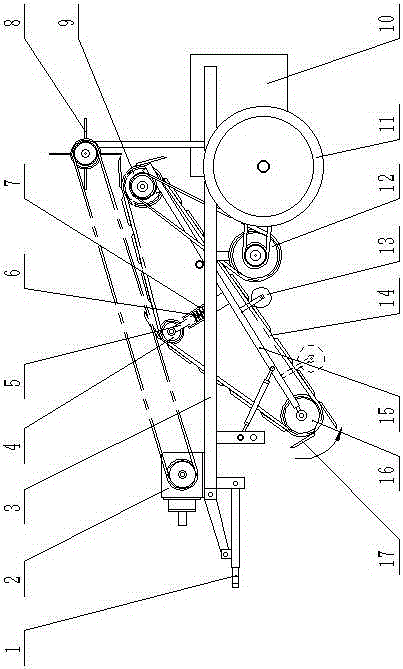

[0015] refer to figure 1 , is an embodiment of a finger chain type residual film recovery machine, including a traction device (1), a frame (3), a film collection device, a film collection transmission system (12), a film removal device (8), a film removal device The transmission system (2), ground wheel (11) and residual film box (10), are characterized in that the traction device (1) is set on the front side of the frame (3), and the film collecting device is set in the middle of the frame (3). The film device (8) is arranged above the rear side of the film collecting device, the residual film box (10) is arranged on the rear side of the film collecting device, and the film collecting drive system (12) and the film stripping drive system (2) are respectively arranged on the frame (3 ), the film-retracting drive system (12) connects the ground wheel (11) with the film-retracting device, the stripping drive system (2) is connected with the stripping device (8), and the ground ...

Embodiment 2

[0017] The difference between this embodiment and embodiment 1 is that the lower film sprocket (16) is a flat belt pulley.

Embodiment 3

[0019] The difference between this embodiment and embodiment 1 is that the tensioning sprocket (4) is a flat pulley.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com