Decarboxylation device for process using adipic acid to prepare cyclopentanone

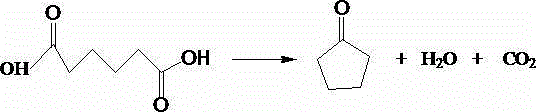

A technology of adipic acid and cyclopentanone, which is applied in the fields of condensation preparation of carbonyl compounds, chemical instruments and methods, organic chemistry, etc., can solve problems such as reducing the conversion rate of adipic acid, long decarboxylation period of adipic acid, and increasing production costs. , to achieve the effect of high separation efficiency, short reaction period and increased output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

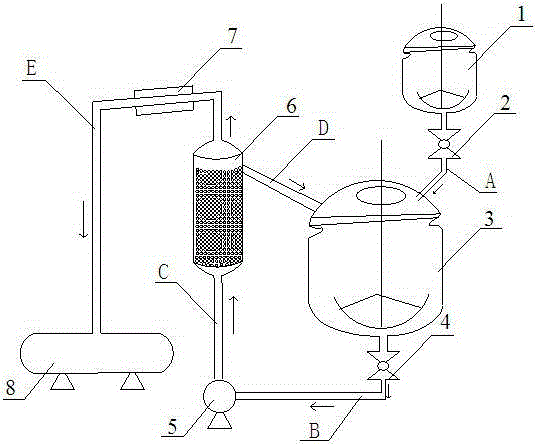

[0029] like figure 1 As shown, the decarboxylation device for preparing cyclopentanone from adipic acid in the present invention includes a dissolution tank 1 for containing and melting adipic acid. The dissolution kettle 1 is connected to the reaction kettle 3 through the first pipeline A, and the first pipeline A is provided with a first valve 2, in order to prevent backflow, the first valve 2 is a one-way valve. Both the dissolution kettle 1 and the reaction kettle 3 include a stirring device and a heating device. The purpose of the heating device is to heat and keep warm, so that the adipic acid is in a molten state, and the stirring device ensures uniform heating.

[0030] The reaction kettle 3 is connected to the inlet of the circulation pump 5 through the second pipeline B, and the second pipeline B is provided with a second valve 4. In order to prevent backflow, the second valve 4 is a one-way valve; the outlet of the circulation pump 5 passes through the third pipeli...

Embodiment 2

[0036] Use the device disclosed in embodiment 1 to prepare the processing method of cyclopentanone:

[0037] 1) Add adipic acid into the dissolution kettle 1, and heat it to 190-200°C, and at the same time, heat the temperature of the heat transfer oil in the reaction kettle 3 to 230-245°C;

[0038] 2) When the adipic acid is completely melted into liquid, open the first valve 2, and the liquid adipic acid enters the reactor 3 from the dissolution tank 1, and when the temperature of the adipic acid in the reactor 3 rises to 210-220°C, open it The second valve 4 opens the circulating pump 5, and the adipic acid is pumped to the fixed-bed reactor 6. The fixed-bed reactor 6 is equipped with a barium hydroxide catalyst, and the adipic acid passes through the catalyst in the fixed-bed reactor 6 from bottom to top. ;

[0039] 3) The gaseous cyclopentanone generated by the reaction flows into the receiver 8 through the fifth pipeline E, and the cyclopentanone is cooled to liquid dur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com